Straw fermented coarse feed and preparation method thereof

A roughage and straw technology, applied in animal feed, animal feed, applications, etc., can solve the problems of unfavorable food safety, lack of formulated feed, unfavorable growth of mutton sheep, etc., to improve gastrointestinal absorption capacity, no drug residue, palatability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

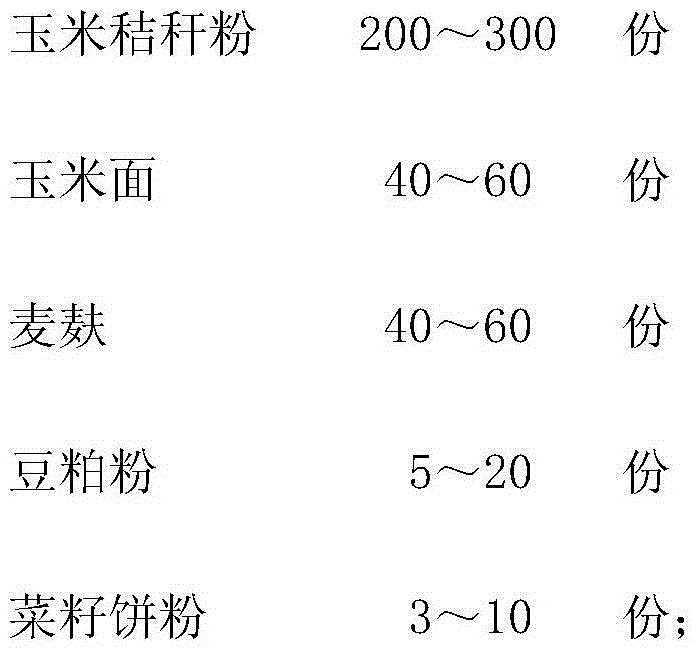

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of the straw fermented roughage comprises the following steps:

[0050] Preparation of beneficial bacteria liquid

[0051] Take non-polluted deep well water, add corn flour, wheat flour, brown sugar, starch, pour into a container and seal it for fermentation;

[0052] Fermentation time: when the daily average temperature is 35 degrees, it can be fermented in 1 day; when the daily average temperature is 30 degrees, it can be fermented in 2 to 3 days; when the daily average temperature is 25 degrees, it can be fermented in 7 days to 10 days; When the temperature is 15 degrees, it can be fermented in 13 to 17 days; when the daily average temperature is lower than 10 degrees, it is necessary to take measures to increase the temperature for fermentation, and heat the used clean water to warm water of about 25 degrees to facilitate early fermentation;

[0053] Preparation of Corn Stalk Meal

[0054] The corn stalks harvested in autumn, after more than...

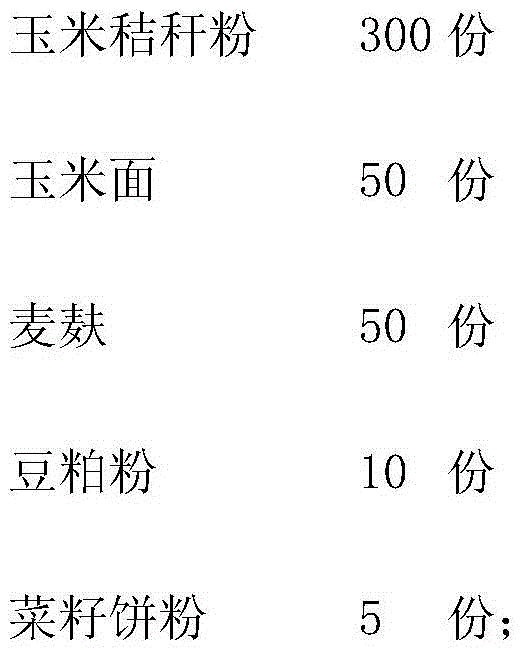

Embodiment

[0065] 1. Preparation of beneficial bacteria liquid

[0066] 1. Fermentation raw materials: Take 100 jin of clean water from a deep well without pollution, add 30 jin of corn flour, 10 jin of wheat flour, 4 jin of brown sugar, and 4 jin of starch, stir evenly, pour it into a dissolver and seal it, so that Sealing can not leak, carry out fermentation.

[0067] 2. Fermentation time: when the daily average temperature is 35 degrees, it can be fermented in 1 day; when the daily average temperature is 30 degrees, it can be fermented in 2 to 3 days; when the daily average temperature is 25 degrees, it can be fermented in 7 days to 10 days; When the daily average temperature is 15 degrees, it can be fermented in 13 to 17 days; when the daily average temperature is lower than 10 degrees, measures should be taken to increase the temperature for fermentation, and the clean water used should be heated to warm water of about 25 degrees to facilitate early fermentation.

[0068] 2. Prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com