Equipment of garbage transfer station

A technology for garbage transfer vehicles and transfer stations, which is applied in trash cans, garbage conveying, garbage collection, etc. It can solve the problems of large overflow loss and throttling loss, low mechanical efficiency, hidden safety hazards, etc., so as to reduce energy loss, mechanical The effect of improving efficiency and preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

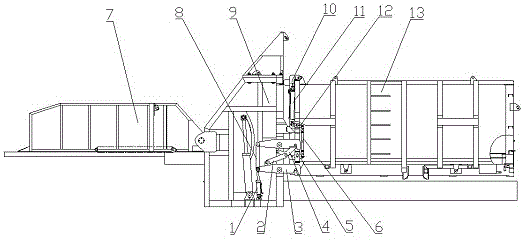

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

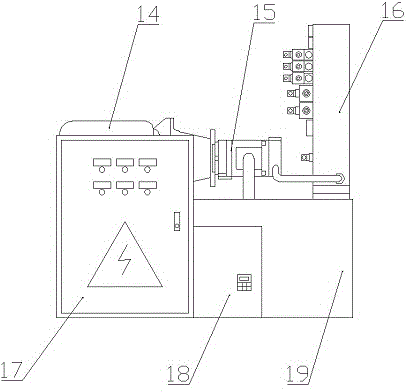

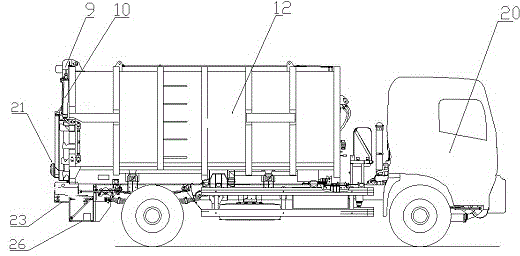

[0025] Such as Figure 1 to Figure 5 As shown, the garbage transfer station equipment of the present invention includes a garbage compressor 9, a garbage transfer vehicle 20 with a detachable garbage bin 13 and a control device, and the control device includes a fuel tank 19, a motor 14, an oil pump 15, a programming controller 17 and an oil pump. The road block assembly 16 also includes a frequency converter 18 and an inductor (not shown in the figure) used to sense the working conditions of the garbage compressor 9. The sensor is electrically connected to the programming controller 17, and the programming controller 17 and the frequency converter 18 Electric connection, the frequency converter 18 is electrically connected with the motor 14; one end of the docking of the garbage compressor 9 and the garbage bin 13 is provided with a first hydraulic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com