Method and device for recycling low-concentration brine

A brine circulation and low-concentration technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as increasing consumption, affecting the ecological environment, and increasing costs, and achieve reduction The effect of production cost, less human resources and low infrastructure cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: a kind of low-concentration saline brine recycling method comprises the following steps:

[0033] S10, collecting salt water, collecting salt water with a concentration of 15%;

[0034] S20, filtering, filtering the brine, and removing large particles of impurities and fine impurities in the brine in turn;

[0035] S30, activated carbon adsorption, through activated carbon to absorb free substances in the filtered brine, and remove peculiar smell, to obtain filtered and purified brine, the activated carbon is in the form of powder, granular and cylindrical activated carbon, selected from fruit shell activated carbon , wood activated carbon, coal-based activated carbon, any one or their mixture, the three activated carbons have good adsorption effect on the organic matter and pigment in the brine;

[0036] S40, chemical sterilization, adding sodium hypochlorite solution to the filtered and purified salt water to remove harmful microorganisms in the salt wa...

Embodiment 2

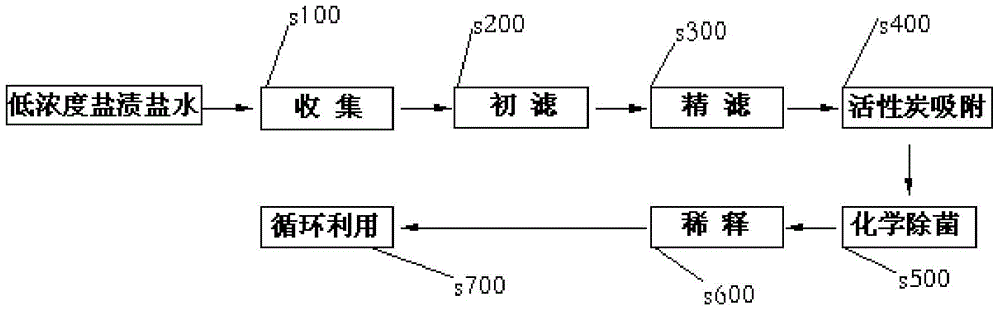

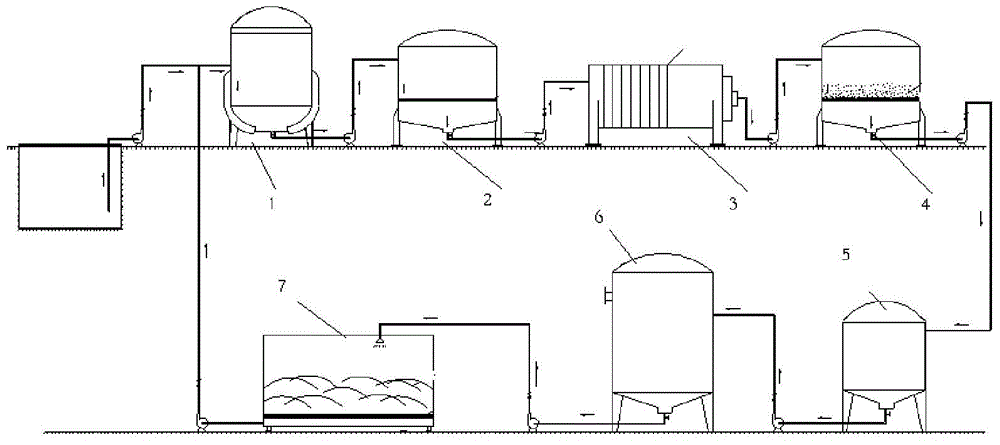

[0039] Embodiment 2: low-concentration saline brine recycling method, such as figure 1 shown, including the following steps:

[0040] S100, collecting brine, collecting brine with a concentration of 10%;

[0041] S200, initial filtration, the brine is initially filtered through the filter to remove large particles of impurities in the brine, among which, the filter of various materials that can remove large particles of impurities can be used in the initial filtration, generally speaking, the filter is made of metal It is made of silk, and the appropriate filter mesh diameter is selected according to the specific conditions of impurities contained in the brine. Generally, the mesh diameter of the filter mesh is at least 20 mesh;

[0042] S300, fine filtration, the brine after primary filtration is fine-filtered by a filter press to remove fine impurities in the brine, and the fine filter can be selected with a large processing capacity, low cost, good filtering effect, and is...

Embodiment 3

[0047] Embodiment 3: the same as Embodiment 2, the difference is:

[0048] S300, fine filtration, performing fine filtration on the brine after the preliminary filtration through a plate and frame filter press, so as to remove fine impurities in the brine;

[0049] S400, activated carbon adsorption, through the shell activated carbon to absorb the free substances in the finely filtered brine, and remove the peculiar smell, so as to obtain the filtered and purified brine, wherein the temperature of the finely filtered brine is kept at 45 °C, and the fruit shell activated carbon is added The amount is 5.0% of the brine after fine filtration, and the adsorption time is 60 minutes;

[0050]S500, chemical sterilization, adding sodium hypochlorite solution to the filtered and purified brine to remove harmful microorganisms in the brine, wherein the concentration of the sodium hypochlorite solution is 3mg / L, and the sterilization time is 50min;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com