Preparation method of carbon fiber reinforced polyether ether ketone composite material

A technology of polyether ether ketone and composite materials, which is applied in the fields of carbon fiber, fiber treatment, chemical instruments and methods, etc. It can solve the problems of difficult three-dimensional weaving technology, high difficulty in cleaning machines, high viscosity of PEEK resin, etc., and achieve excellent mechanical properties and thermal stability, flexible processing, and low elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

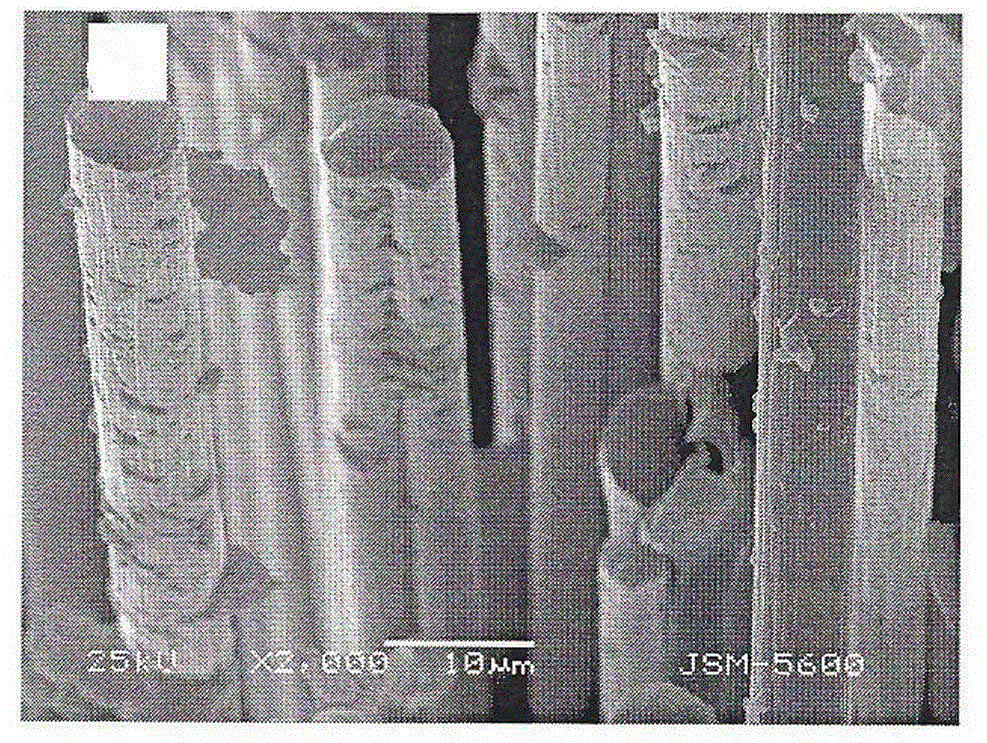

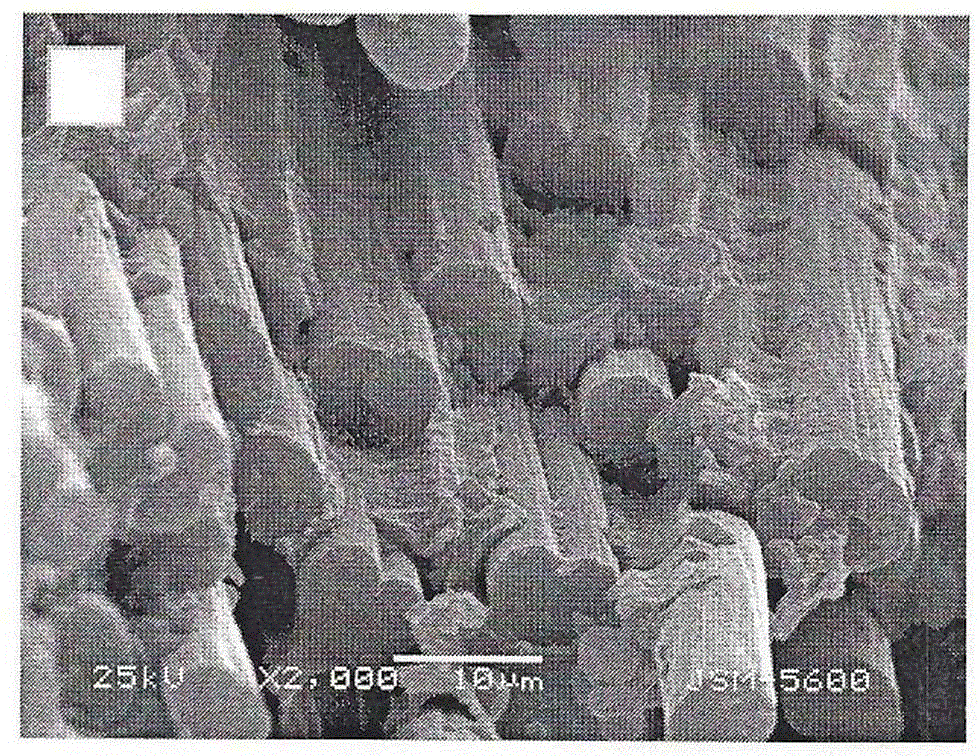

[0022] Weave the carbon fiber into a 2D woven plain weave preform, the weaving angle θ=90°, and then soak the woven preform in acetone for 48 hours, and then use a mixed acid: (sulfuric acid: nitric acid = 3:2) to ultrasonicate for 20 minutes , its microscopic appearance is as figure 1 As shown, rinse with deionized water and dry. Dissolve diphenyl sulfone (DPS) in an appropriate amount of acetone and stir. After the diphenyl sulfone (DPS) is fully dissolved, add polyetheretherketone (PEEK) powder in a proportion of 80% by mass, fully stir, and steam the acetone and then dry the powder. Dry to obtain a polyetheretherketone / diphenylsulfone (PEEK / DPS) mixture. Weigh out an appropriate amount of the mixture, and hot press it at 390°C and pressure 3 MPa to form a pure polyetheretherketone resin sheet, during which diphenyl sulfone (DPS) sublimates. According to the carbon fiber (CF) volume fraction of 45% and polyetheretherketone (PEEK) volume fraction of 65%, the obtained dry p...

Embodiment 2

[0024] The carbon fiber is woven into a 2D woven plain weave preform, the braiding angle θ=90°, and then the woven preform is soaked in acetone for 48 hours, and then ultrasonicated with mixed acid (sulfuric acid: nitric acid = 3:2) for 20 minutes. Rinse with deionized water and dry. Dissolve diphenyl sulfone (DPS) in an appropriate amount of acetone and stir. After the diphenyl sulfone (DPS) is fully dissolved, add polyetheretherketone (PEEK) powder in a proportion of 80% by mass, fully stir, and steam the acetone and then dry the powder. Dry to obtain a polyetheretherketone / diphenylsulfone (PEEK / DPS) mixture. Weigh out an appropriate amount of the mixture, and hot press at 390°C and pressure 4 MPa to form a pure polyetheretherketone (PEEK) resin sheet, and diphenyl sulfone sublimes during the hot pressing process. According to the carbon fiber (CF) volume fraction of 60% and the polyetheretherketone (PEEK) volume fraction of 40%, the obtained dry preform and the prepared po...

Embodiment 3

[0026] The carbon fiber is woven into a 2D woven plain weave preform, the braiding angle θ=90°, and then the woven preform is soaked in acetone for 48 hours, and then ultrasonicated with mixed acid (sulfuric acid: nitric acid = 3:2) for 20 minutes. Rinse with deionized water and dry. Dissolve diphenyl sulfone (DPS) in an appropriate amount of acetone and stir. After the diphenyl sulfone (DPS) is fully dissolved, add polyetheretherketone (PEEK) powder in a proportion of 80% by mass, fully stir, and steam the acetone and then dry the powder. Dry to obtain a polyetheretherketone / diphenylsulfone (PEEK / DPS) mixture. Weigh out an appropriate amount of the mixture, and heat-press it at 390°C under a pressure of 4 MPa to form a pure polyetheretherketone (PEEK) resin sheet, during which diphenyl sulfone sublimates. According to the carbon fiber (CF) volume fraction of 70% and the polyetheretherketone (PEEK) volume fraction of 30%, the obtained dry preform and the prepared polyethereth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com