High glow-wire ignition temperature halogen-free flame-retardant reinforced nylon composite and preparation method thereof

A technology of nylon composite material and light-off temperature, which is applied in the field of nylon materials, can solve problems such as endangering physical and mental health, failing to meet safety requirements, and inability to light-off, etc., to achieve easy process operation, simple preparation method, and high light-off temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

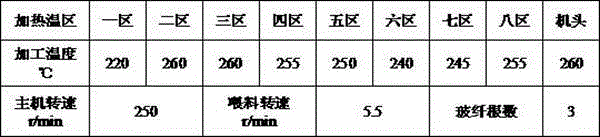

Method used

Image

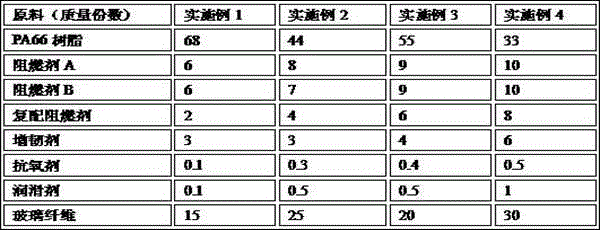

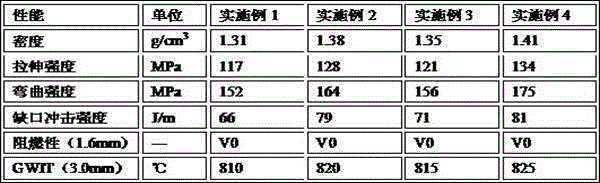

Examples

Embodiment approach

[0038] The viscosity of the PA66 resin in the present invention is 2.0~2.5Pa·S, specifically, the PA66 resins produced by Shenma Industrial Co., Ltd. with the grades of EPR24, EPR27, EPR32 and FYR27 can be selected, as an embodiment of the present invention, The preferred grade is PA66 resin of EPR24.

[0039] The invention adopts a novel composite flame retardant system, and obtains a highly efficient, low-smoke, non-toxic halogen-free flame retardant reinforced nylon composite material through multiple flame retardant effects of gas phase and condensed phase flame retardants. The flame retardant A is any one or a combination of OP1312 and OP1314. The flame retardant B is any one or a combination of melamine pyrophosphate and melamine polyphosphate. When the flame retardant B is thermally decomposed, it can absorb a large amount of heat, thereby reducing the temperature of the material and achieving the effect of flame retardancy. . The compound flame retardant is obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com