Papermaking rubber roller with high-strength non-woven and production process

A production process, non-woven technology, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problems of short service life, high temperature and high pressure resistance, etc., and achieve the effect of long service life, long life cycle and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

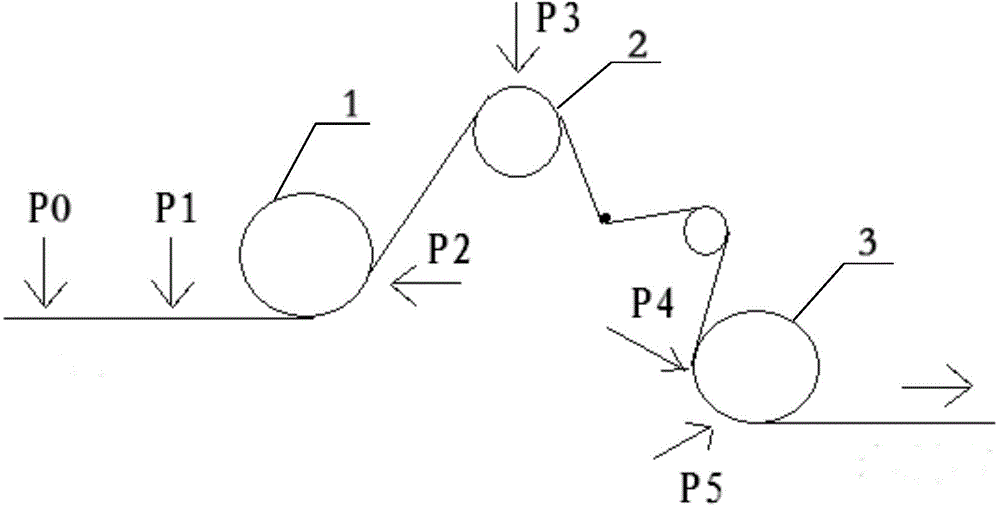

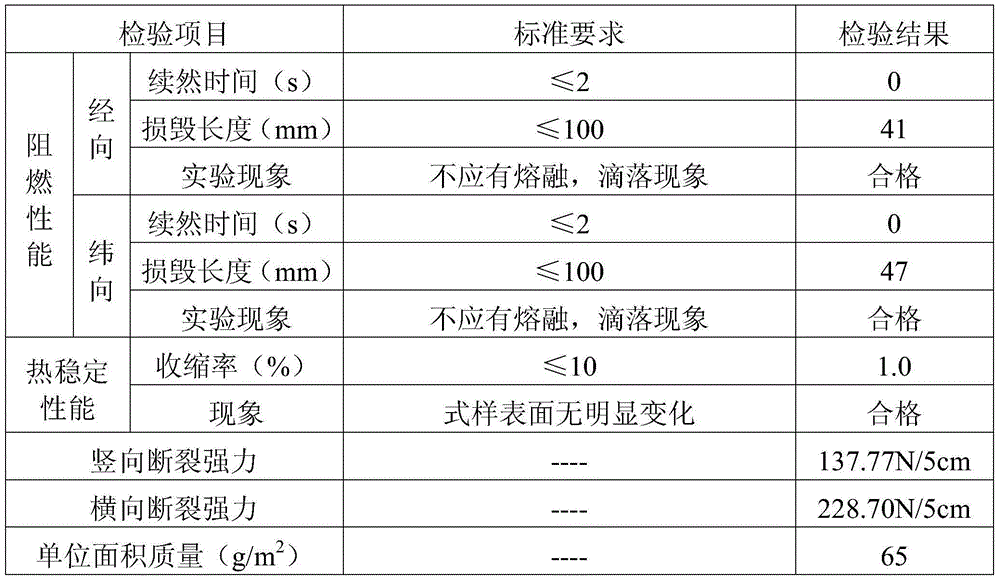

[0024] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0025] The invention is a high-strength non-woven fabric for paper-making rubber rollers, which is made of aramid 1414 fibers through a hydroentanglement process. The specific production process is: A. Opening: the aramid fiber is accurately weighed by an electronic scale, and then quantitatively transported to the rough opener for preliminary opening of the aramid fiber; Cotton box, to mix the aramid fiber evenly, and add 5% conductive fiber at the same time; then send the aramid fiber to the fine opening machine, where the fiber raw material is finely opened to make the fiber more fluffy;

[0026] B. Carding: Feed the finely opened aramid fibers into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com