Characterization method and device for in-situ unsteady surface chemical reaction

A chemical reaction and surface reaction technology, applied in scientific instruments, measuring devices, instruments, etc., can solve problems such as inability to achieve in-situ online detection of products and dynamic trends, poor stability, and poor synchronization with coal temperature changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

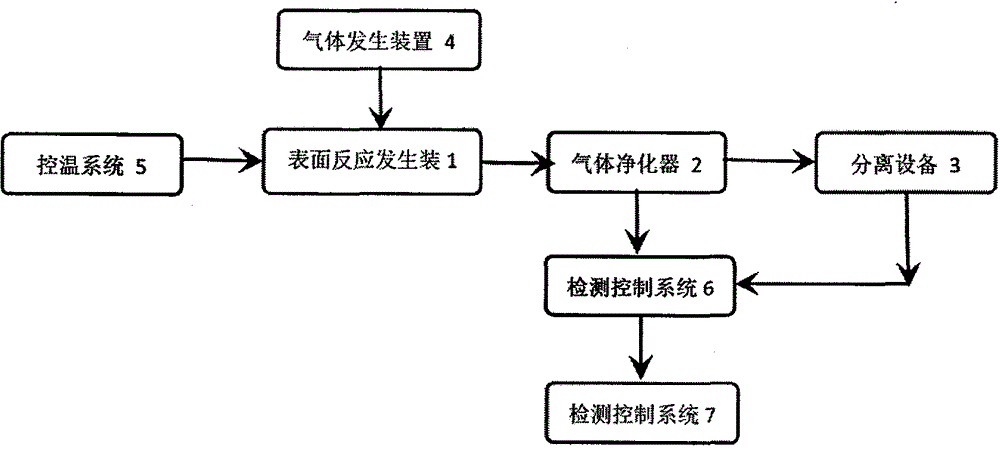

Embodiment 1

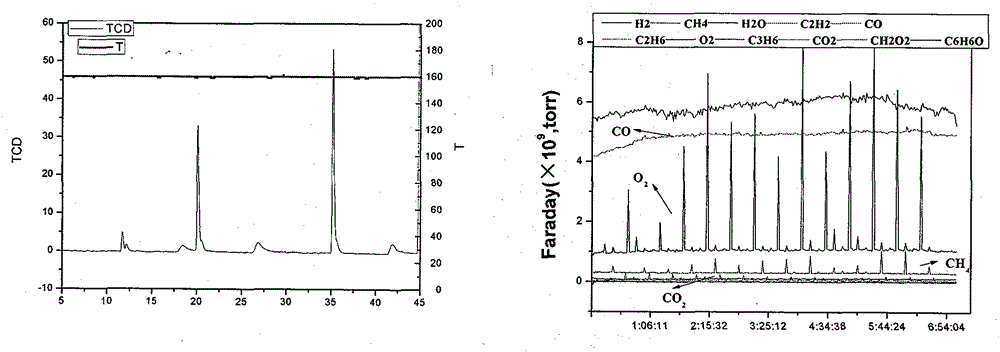

[0019] Example 1: The method of in-situ coal pyrolysis and semi-coke gasification reaction is as follows: firstly crush and sieve the coal block to the required particle size, dry the coal sample, take an appropriate amount and put it into the surface generating device, and then press a certain flow rate The carrier gas is introduced, and the temperature is programmed at different heating rates to the experimental predetermined temperature for a period of time to make semi-coke. During the pyrolysis process, the chromatographic mass spectrometer performs simultaneous and online detection of the pyrolysis products to quickly reflect the changes on the surface of the coal sample, and then The semi-coke sample is not taken out, and the gas generator is used to inject water vapor into the surface generator in situ to fully contact the semi-coke coal sample for gasification reaction. During the experiment, the gas generated in the surface generator is purified by the purifier Enter ...

Embodiment 2

[0021] Example 2: The method for catalytic reaction of in-situ methanation of synthesis gas is: first, grind or sieve the catalyst to the required particle size, take an appropriate amount and load it into the surface generating device, then feed the synthesis gas according to a certain flow rate and ratio, and heat up to The predetermined temperature of the experiment is constant, under a certain pressure, and then the synthetic gas is pumped into the surface generating device by the gas generating device to fully contact the catalyst for methanation reaction. During the experiment, the generated gas generated in the surface generating device is purified by the purifier and enters the The separation equipment is separated, and the detection and control system detects the H in the separated generated gas. 2 , CO 2 , CO and CH 4 Quantitative analysis of the gas concentration is carried out, and then the syngas enters another detection system for its simultaneous online qualita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com