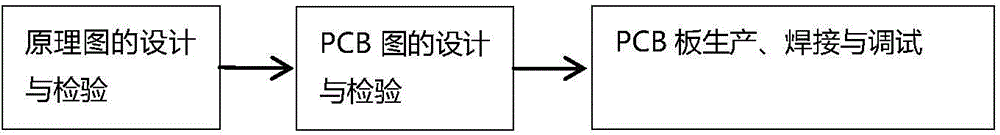

Quality control system and method for PCB design and production

A control system and quality technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve problems that cannot be realized, and achieve the effect of ensuring quality, improving finished quality, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

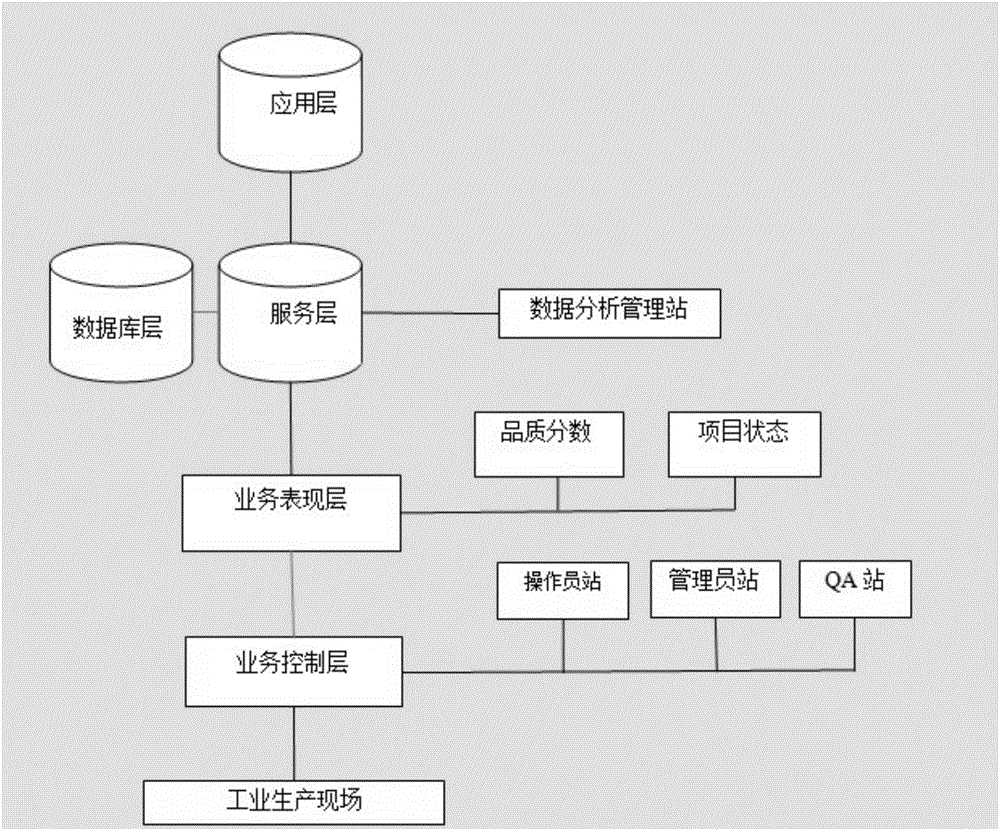

[0056] Such as figure 2 As shown, the quality control system used for PCB design and production includes a database layer, a service layer, an application layer, a business performance layer, and a business control layer;

[0057] The database layer uses a data recorder to record various data information during the production process, including storing the data obtained from the industrial production site to be measured in the production process, the production process control data, and the design and production through PCB The calculated data obtained by feedback from the quality control system of the company;

[0058] The service layer is built on a service-oriented computer platform, and the production data obtained in the database layer is analyzed according to the algorithm to obtain feedback data, including the weight percentage of each influencing factor in the production process, the quality percentage of each process, and the overall project The quality and quality score...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com