Method and device for manufacturing a fiber optic microring resonator

A technology of a micro-ring resonator and a manufacturing method, applied in the field of optical fiber integration, can solve the problems of obstruction, low coupling efficiency, and high production cost, and achieve the effects of simple manufacturing process, improved coupling efficiency, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

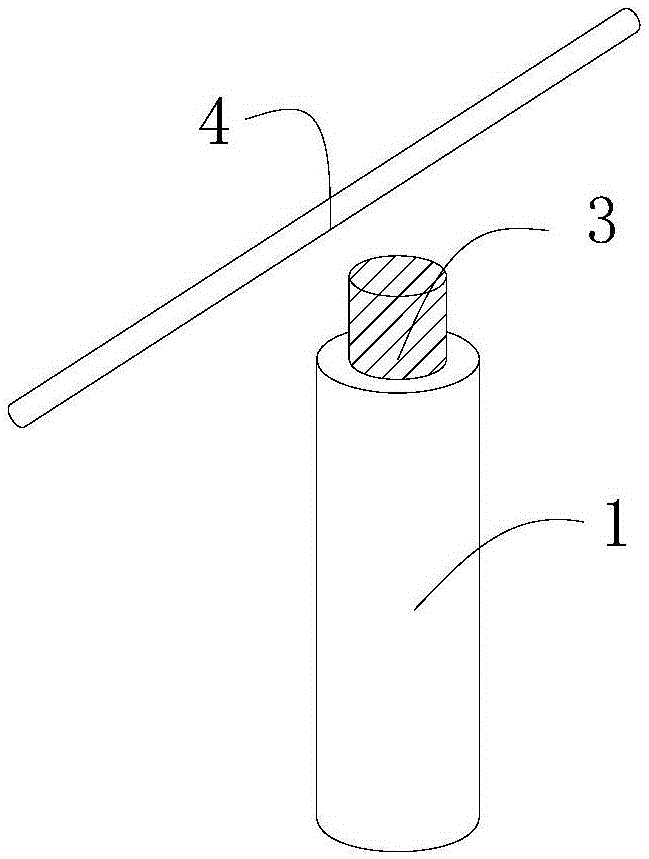

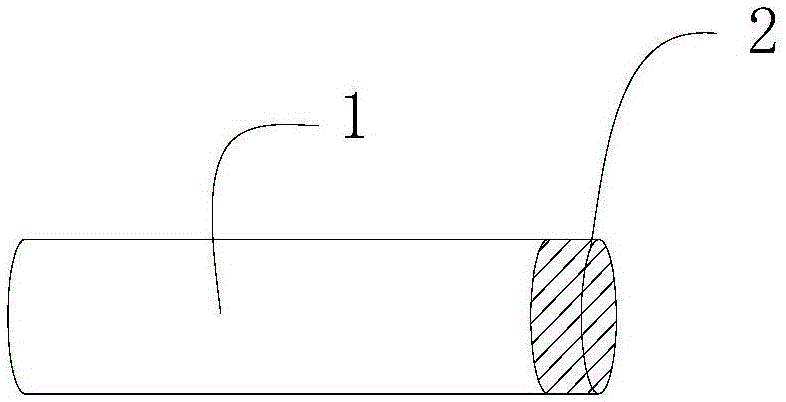

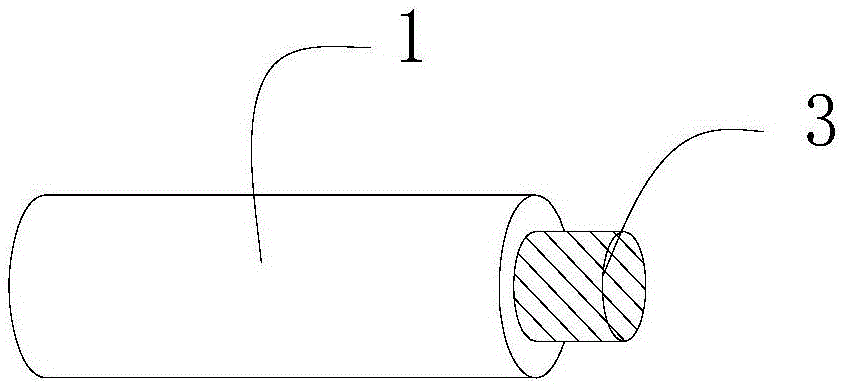

[0029] Such as figure 1 Shown is a schematic diagram of a manufacturing method of an optical fiber microring resonator according to an embodiment of the present invention, which specifically includes the following steps:

[0030] A1. Coating a layer of waveguide material film on the end face of a section of optical fiber;

[0031] The refractive index of the waveguide material film is larger than that of the optical fiber material. The larger the refractive index of the selected waveguide material film is, the smaller the bending loss is. In actual operation, pure silicon film, silicon nitride film and silicon nitride film can be used. film, or a polymer optical waveguide material as the coating material, and silicon nitride material is selected as the coating material in the embodiment of the present invention.

[0032] The specific operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com