Drum type dehydration device for lotus root starch slurry and dehydration method thereof

A dehydration device, a drum-type technology, applied in food preparation, food drying, food science and other directions, can solve the problems of reduced work efficiency, dehydration efficiency, difficult maintenance, etc., to improve work efficiency, improve processing efficiency, and ensure continuity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

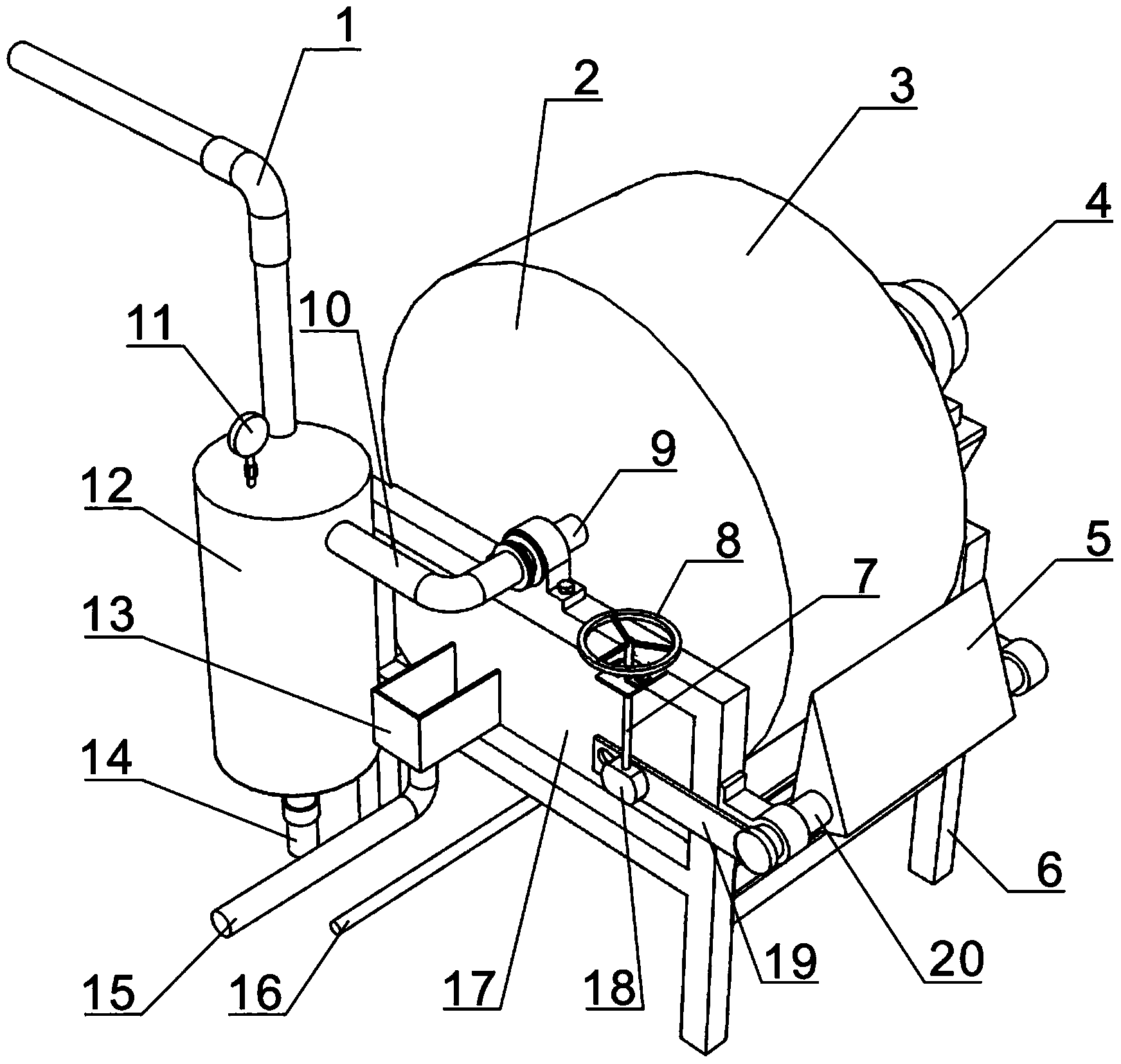

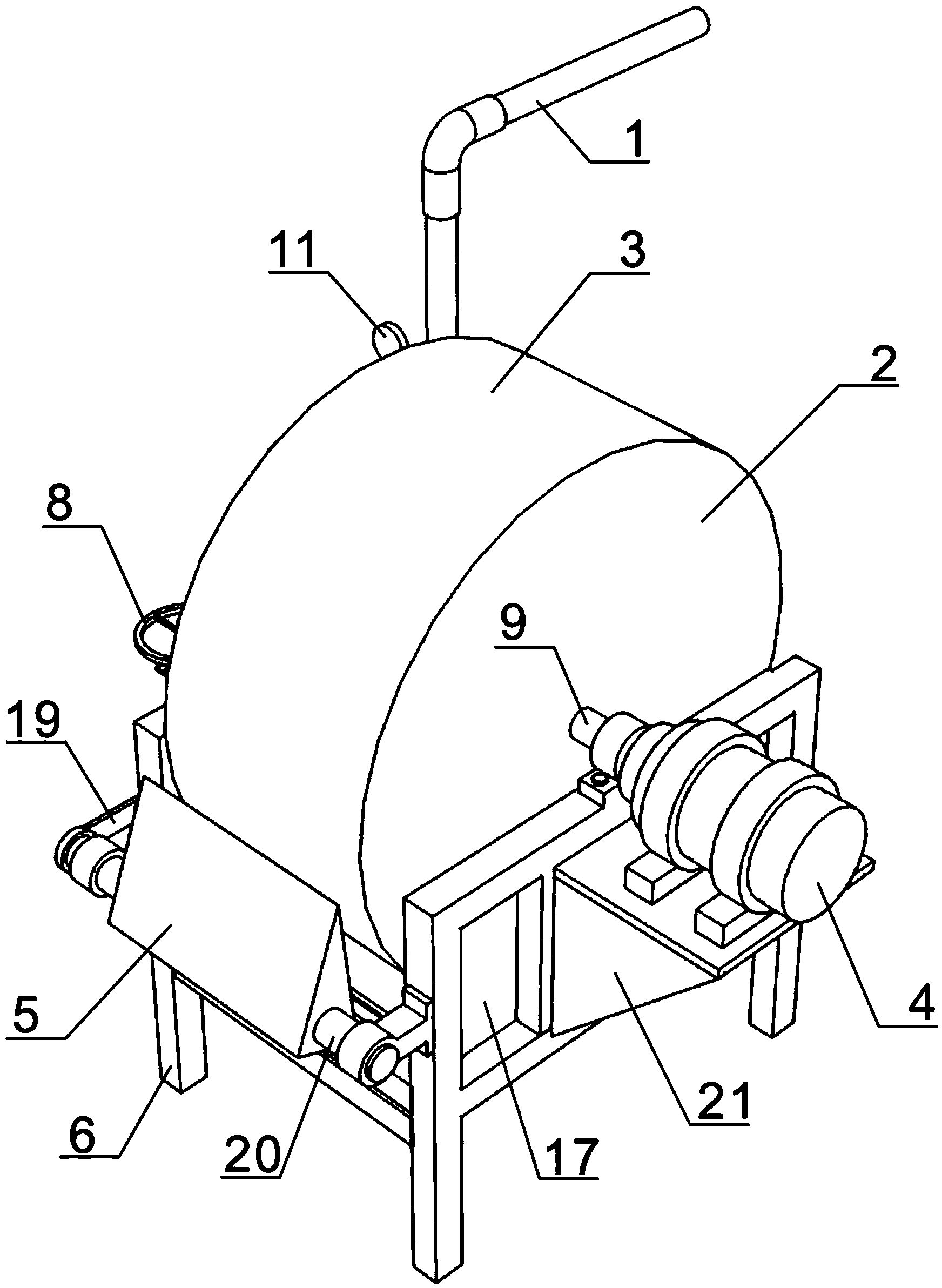

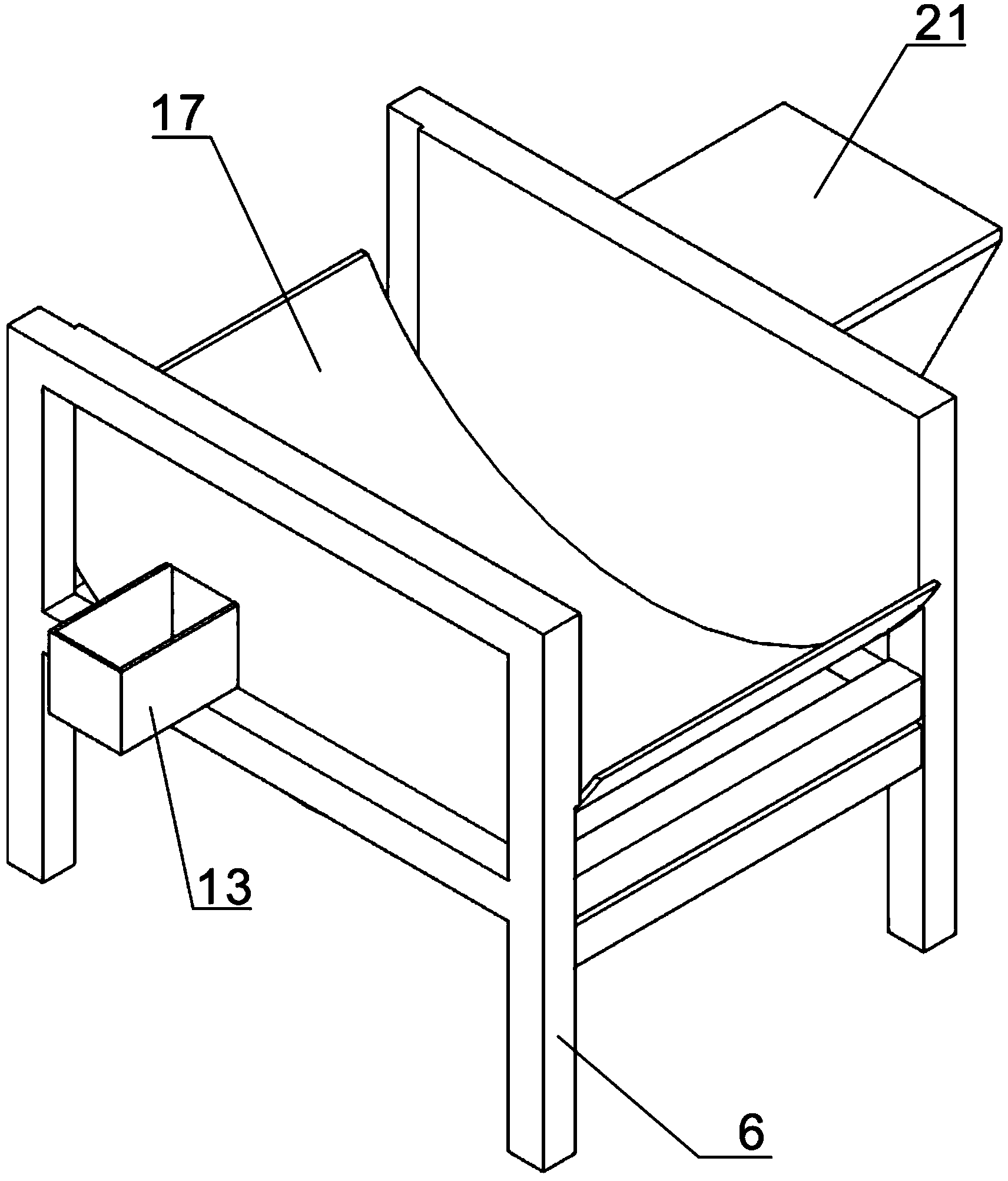

[0047] Embodiment 1: Pour the lotus root powder slurry into the storage tank 17 through the feed pipe 15 and the feed tank 13, and ensure that the liquid level of the lotus root powder slurry is higher than the lowest point of the outer wall of the drum 3 by 1 cm; The air inside is pumped out and exhausted through the exhaust pipe 1; start the motor 4, and the motor 4 drives the drum 3 to rotate at a speed of 40rpm / min; when the pressure value displayed on the pressure gauge 11 is 0.075MPa, turn the handwheel 8 to drive the adjusting bolt 7. Make the adjustment block 18 move in the waist-shaped hole at the end of the adjustment plate 19, finally drive the cutter 5 to rotate around the cutter rotary rod 20 so that the edge of the cutter turns to the drum 3, and the distance between the edge of the cutter 5 and the stainless steel mesh 2 is kept at 12mm; The knife 5 cuts off the lotus root powder layer gathered on the outer surface of the stainless steel mesh 2. After the dehydra...

Embodiment 2

[0048] Embodiment 2: the lotus root powder slurry is poured into the storage tank 17 through the feed pipe 15 and the feed tank 13, and the liquid level of the lotus root powder slurry is guaranteed to be 1.5cm higher than the lowest point of the outer wall of the drum 3; The air in 3 is pumped out and exhausted through the exhaust pipe 1; start the motor 4, and the motor 4 drives the drum 3 to rotate at a speed of 80rpm / min; when the pressure value displayed on the pressure gauge 11 is 0.078MPa, turn the handwheel 8 to drive the adjustment The bolt 7 makes the adjustment block 18 move in the waist-shaped hole at the end of the adjustment plate 19, and finally drives the cutter 5 to rotate around the cutter rotary rod 20 so that the edge of the cutter 5 turns to the drum 3, and the distance between the edge of the cutter 5 and the stainless steel mesh 2 is kept At 13.5mm; cutter 5 cuts off the lotus root powder layer gathered on the outer surface of stainless steel mesh 2, and ...

Embodiment 3

[0049] Embodiment 3: the lotus root starch slurry is poured in the storage tank 17 through the feed pipe 15 and the feed tank 13, and the liquid level of the lotus root starch slurry is guaranteed to be higher than the lowest point of the outer wall of the drum 3 by 2 cm; The air inside is drawn out and exhausted through the exhaust pipe 1; start the motor 4, and the motor 4 drives the drum 3 to rotate at a speed of 120rpm / min; The bolt 7 makes the adjustment block 18 move in the waist-shaped hole at the end of the adjustment plate 19, and finally drives the cutter 5 to rotate around the cutter rotary rod 20 so that the edge of the cutter 5 turns to the drum 3, and the distance between the edge of the cutter 5 and the stainless steel 2 is maintained. At 15mm; cutter 5 cuts off the lotus root powder layer gathered on the outer surface of stainless steel mesh 2, and after dehydration is completed, close vacuum pump 12 and motor 4, and the remaining slurry in the holding tank 17 i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap