High-pressure smelting atomizing nitrogen-quenching device and method for utilizing device to produce samarium iron nitrogen alloy powder

A technology of alloy powder and nitrogen quenching, applied in the application field of high pressure powder metallurgy, can solve the problems of smelting and production development limitation of samarium iron nitrogen permanent magnet material, uneven and thorough nitriding of SmFe alloy, unstable magnetic properties of alloy powder, etc. Achieve the effect of good powder solidification quality, good powder quality and high powder nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

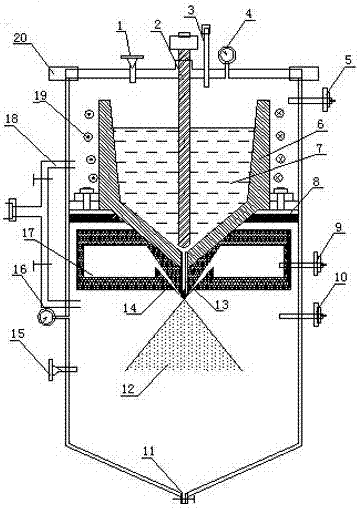

[0040] A high-pressure smelting atomized nitrogen quenching device suitable for producing samarium-iron-nitrogen alloy powder: the high-pressure smelting chamber in the upper part of the main furnace body of the high-pressure smelting atomized nitrogen quenching device in this embodiment is 400 mm high, 300 mm in inner diameter, and 10 mm in wall thickness; The quenching chamber is 500mm high, the inner diameter is 300mm, the wall thickness is 10mm, and the bottom inverted cone is 150mm high. The furnace shell is equipped with a pressure gauge with a maximum range of 6MPa. The crucible 6 of the master alloy melting system is fixed in the melting chamber. The upper part is cylindrical, with a diameter of 100mm and a height of 60mm, and the lower part is an inverted cone, with a diameter of 100mm and a height of 40mm; 8mm, jacket with insulation cotton; crucible 6 is provided with stopper 2, 150mm in length and 10mm in diameter, made of zirconium carbon, the head is closely matc...

Embodiment 2

[0047] A high-pressure smelting atomized nitrogen quenching device suitable for producing samarium-iron-nitrogen alloy powder: the high-pressure smelting chamber in the upper part of the main furnace body of the high-pressure smelting atomized nitrogen quenching device in this embodiment is 800 mm high, 600 mm in inner diameter, and 10 mm in wall thickness; The quenching chamber is 1000mm high, the inner diameter is 600mm, the wall thickness is 10mm, and the bottom inverted cone is 300mm high. The furnace shell is equipped with a pressure gauge with a maximum range of 6MPa. The crucible 6 of the master alloy smelting system is fixed in the smelting chamber. The upper part is cylindrical, with a diameter of 200mm and a height of 120mm, and the lower part is an inverted conical shape with a diameter of 200mm and a height of 80mm; 8mm, jacketed with thermal insulation cotton; the crucible 6 is provided with a plug 2, 300mm long and 15mm in diameter, made of zirconium carbon, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com