Rotational flow dissolved air floatation sewage treatment equipment

A kind of sewage treatment equipment, dissolved air flotation technology, applied in the direction of flotation water/sewage treatment, centrifugal separation water/sewage treatment, etc., can solve the problem of limited treatment capacity, treatment effect, dissolved air release is disturbed by swirl, industrial application Or less inventions, etc., to achieve the effect of saving the amount of gas used for flotation, easy operation and maintenance, and reducing the number of supporting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

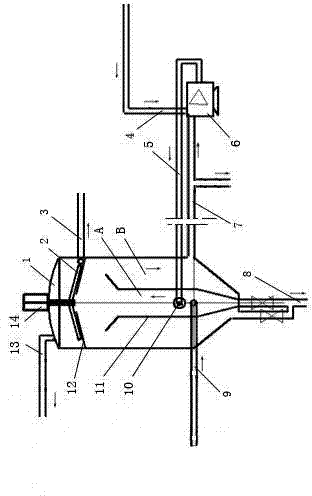

[0021] A swirling dissolved air flotation sewage treatment equipment, including: dissolved air pump 6, releaser 10, slag scraper 2, reducer 14, which is: the top dome head, the middle is a cylinder, and the longitudinal section of the lower part is V The font-shaped tank body 1 is equipped with an inner tank tube 11 whose upper end is a trumpet opening, the middle part is a cylinder, and the longitudinal section of the lower part is V-shaped with the same center line. The bottoms of the tank body 1 and the inner tank barrel 11 are respectively connected with the mud discharge pipeline 8, and the upper fitting position in the tank body 1 is welded with a slagging dome 12 with a through hole in the middle and a tapered longitudinal section; The side wall of the tank body 1 matching the lowest part of the dome 12 is connected to the slag discharge pipe 3 through a flange interface; the center of the outer top of the tank body 1 is provided with a reducer 14, and the reducer 14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com