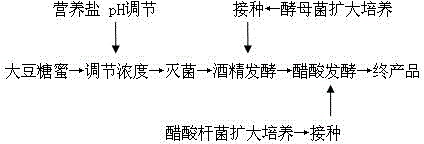

A kind of method utilizing soybean molasses fermentation to produce acetic acid

A technology of soybean molasses and acetic acid, which is applied in the direction of fermentation, etc., can solve the problems of underutilization of active ingredients and waste of resources, etc., and achieve the effects of increasing utilization value, reducing environmental pressure, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: a kind of method utilizing soybean molasses fermentation to produce acetic acid comprises the following steps:

[0027] (1) Preparation of medium

[0028] a. Preparation of yeast culture medium

[0029] Preparation of yeast slant medium: Accurately weigh 40 g of potatoes, peel and cut them into pieces, add 200 mL of distilled water, boil for 30 min, filter with gauze, take the filtrate, then add 4 g of glucose, 3.8 g of agar, the pH is natural, and mix the above The components were dissolved by heating, and divided into test tubes. Each test tube was about 6 mL, wrapped and sterilized. The sterilization condition was 121°C for 20 minutes.

[0030] Preparation of yeast seed medium: Accurately weigh 100 g of potatoes, peel and cut them into pieces, add 500 mL of distilled water, boil for 30 min, filter with gauze, take the filtrate, add 10 g of glucose, and divide into 250 mL Erlenmeyer flasks. 100mL bottle, bandaged and sterilized at 121°C for 20 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com