Fused salt pipeline heating device

A heating device and molten salt technology, applied in pipeline heating/cooling, lighting and heating equipment, solar heating systems, etc., can solve problems such as poor safety performance and low heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

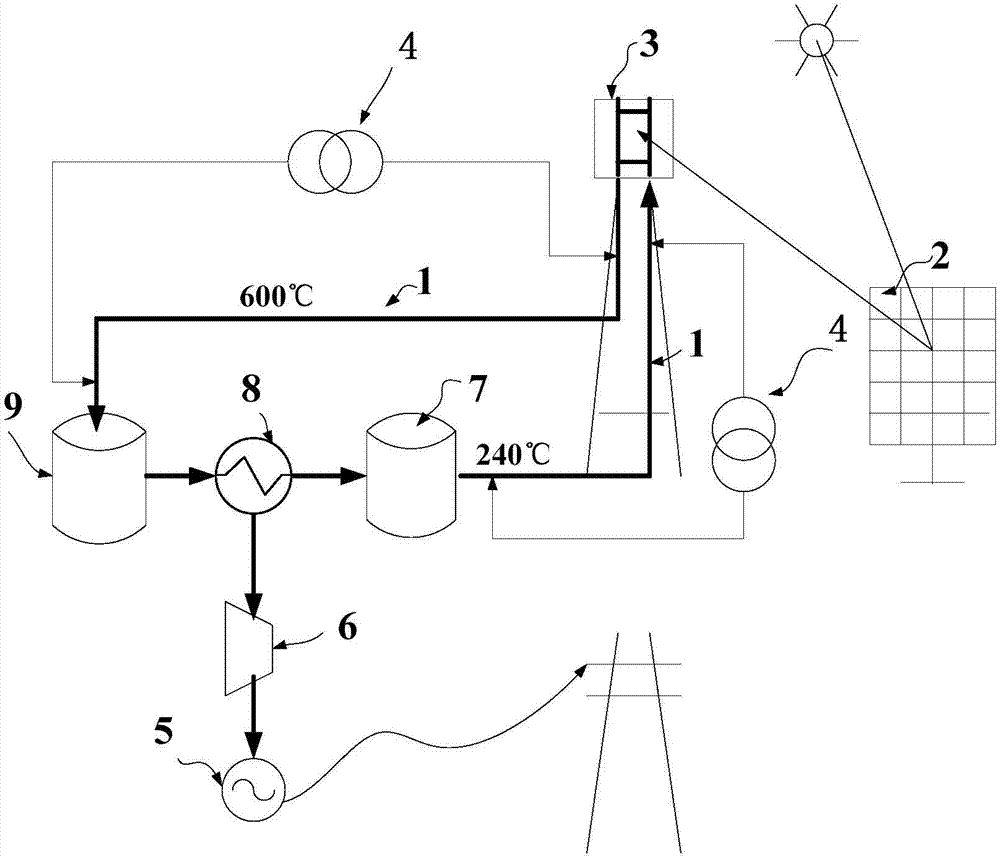

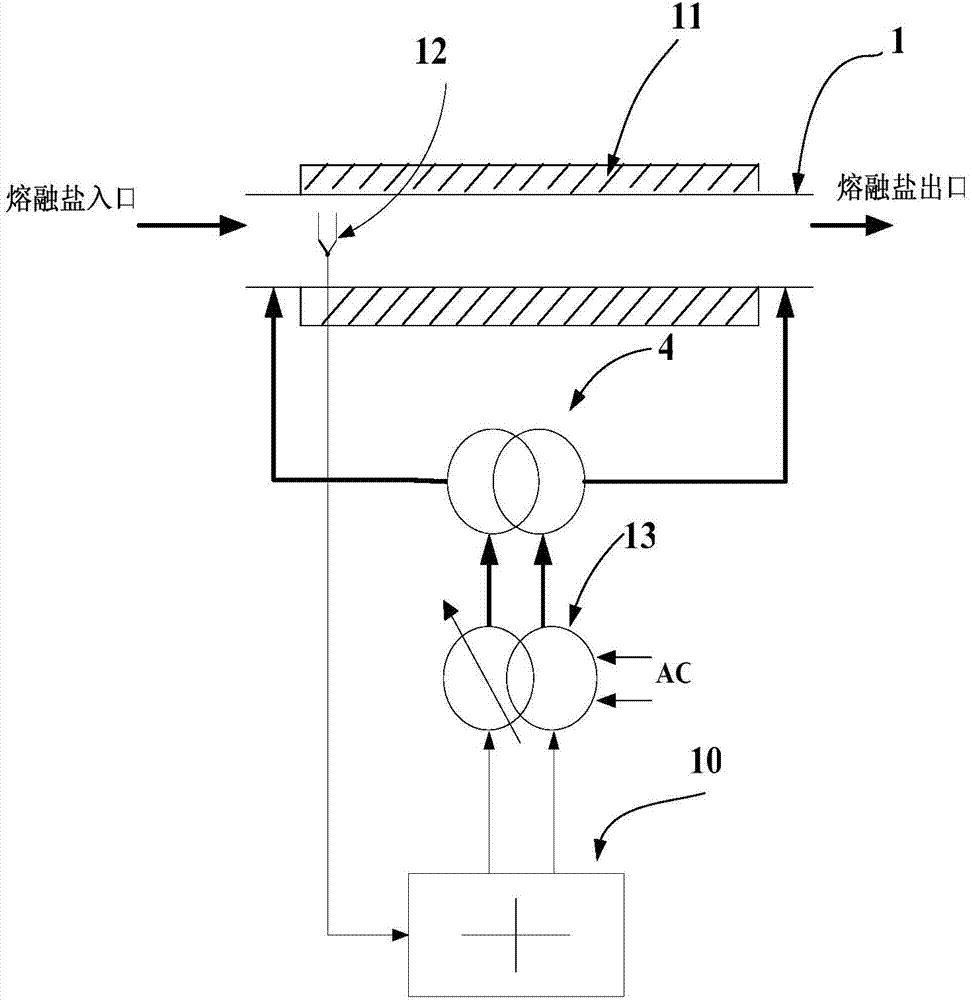

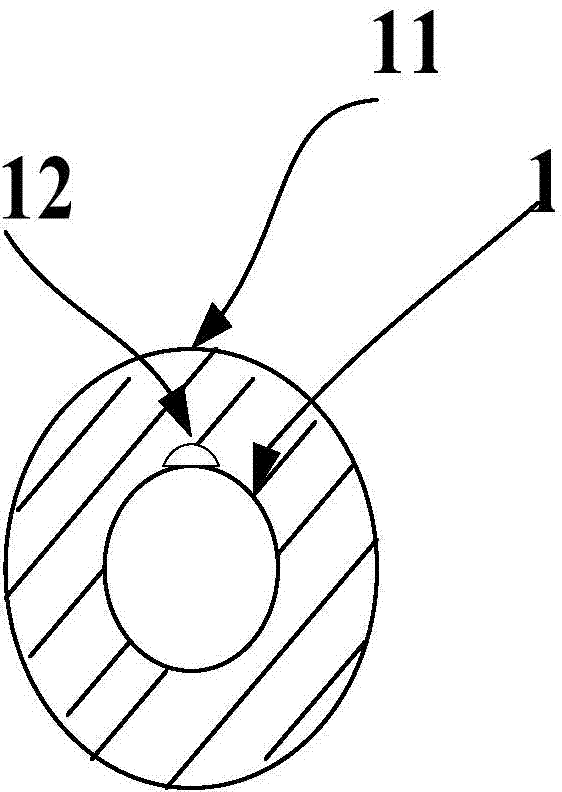

[0017] figure 1 It is a schematic diagram of a tower-type solar concentrating thermal power station using molten salt as a heat-exchanging medium. Such as figure 1 As shown, the tower-type solar concentrating thermal power station using molten salt as the heat exchange medium is mainly composed of heliostat 2, heat absorber 3, molten salt pipeline 1, high-temperature oil tank 9, low-temperature oil tank 7, molten salt Pipeline 1, molten salt pipeline heating device, heat exchanger 8, steam turbine 6, and generator 5 are composed. The heliostat projects the concentrated radiant energy flow on the surface of the heat absorber 3 by reflecting the sun’s rays, and the molten salt in the heat absorber 3 is heated to nearly 600°C, and flows into the high-temperature oil through the molten salt pipeline 1 In the tank 9, the high-temperature molten s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com