Polarizing elements and polarizers

A technology of polarizing element and polarizing plate, applied in the direction of optical element, polarizing element, optics, etc., to achieve the effect of high polarization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086]

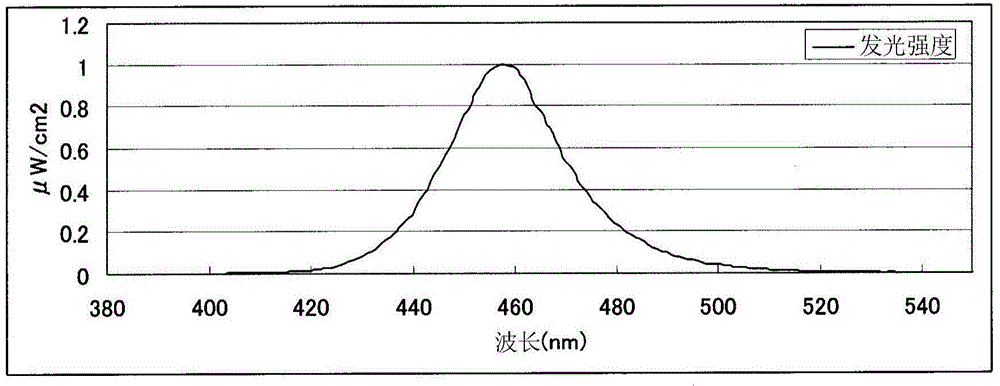

[0087]13.7 parts of 4-aminobenzoic acid were added to 500 parts of water, and dissolved with sodium hydroxide. After cooling, 32 parts of 35% hydrochloric acid was added below 10°C, followed by 6.9 parts of sodium nitrite, and stirred at 5°C to 10°C for 1 hour. 20.9 parts of sodium aniline-ω-methanesulfonate was added thereto, and sodium carbonate was added with stirring at 20°C to 30°C to adjust the pH to 3.5. Stirring is further performed to complete the coupling reaction, and filtration is performed to obtain a monoazo compound. The obtained monoazo compound was stirred at 90 degreeC in the presence of sodium hydroxide, and 17 parts of the monoazo compounds of said formula (3) were obtained. Dissolve 12 parts of the monoazo compound of the above formula (3), 21 parts of 4,4'-dinitrostilbene-2,2'-sulfonic acid in 300 parts of water, and then add 12 parts of sodium hydroxide, The condensation reaction was carried out at 90°C. Subsequently, reduction was performe...

Embodiment 2

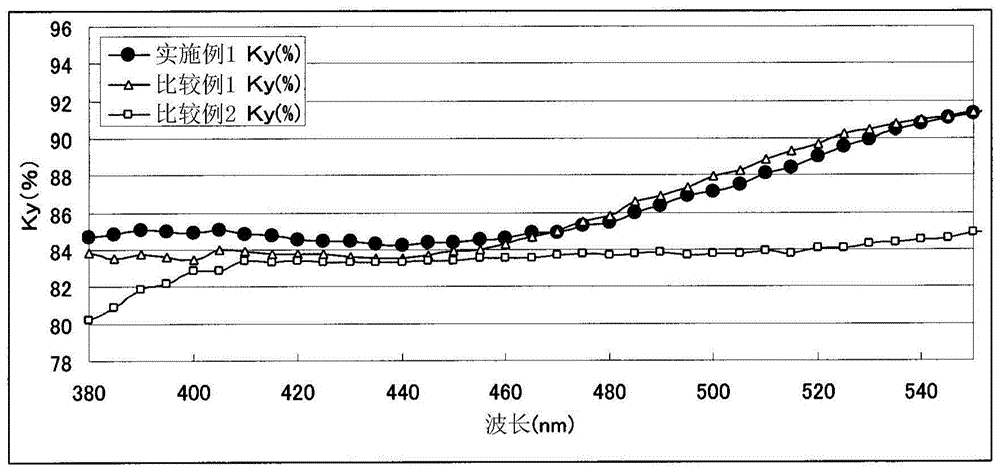

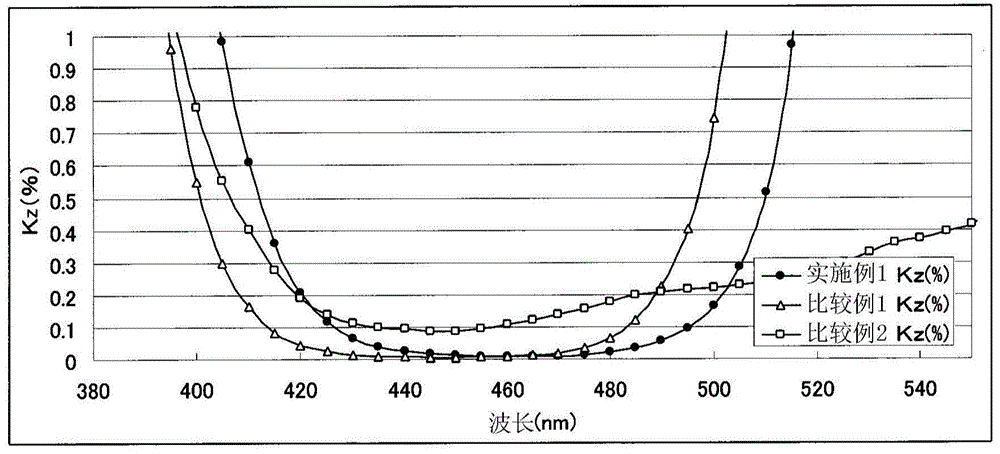

[0091] In the manufacture of the polarizing element of Example 1, the temperature for the dyeing treatment was set to 35° C.; in the proportion of n of the obtained polarizing element, n=1 was 34%, n=2 was 62%, n=2 3 is 4%; except that, a polarizing plate was produced in the same manner, and a measurement sample was produced.

Embodiment 3

[0093] In the preparation of the pigment A of Example 1, after dissolving 21 parts of 4,4'-dinitrostilbene-2,2'-sulfonic acid in 300 parts of water, 12 parts of sodium hydroxide were added, and at 90 Condensation reaction carried out at ℃, in which 12 parts of the monoazo compound of formula (3) is changed to 7 parts to make a dye, and the ratio of n=1 is 15%, n=2 is 84%, n=3 is the dye A of 1% composition, except that, make polarizing element similarly; Except making n=1 in the ratio of n of the obtained polarizing element be 17%, n=2 is 92%, n= Except that 3 was 1%, polarizing plates were produced in the same manner, and measurement samples were produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com