Flavor fish cake taking fish and pork as main raw material and manufacture method thereof

A technology of main raw materials and production methods, applied in food preparation, acid-containing food ingredients, food science, etc., can solve the problems of easy gelatinization, chaotic formula, short shelf life, etc., and achieve elasticity and toughness, stable product quality, Reasonable formula effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

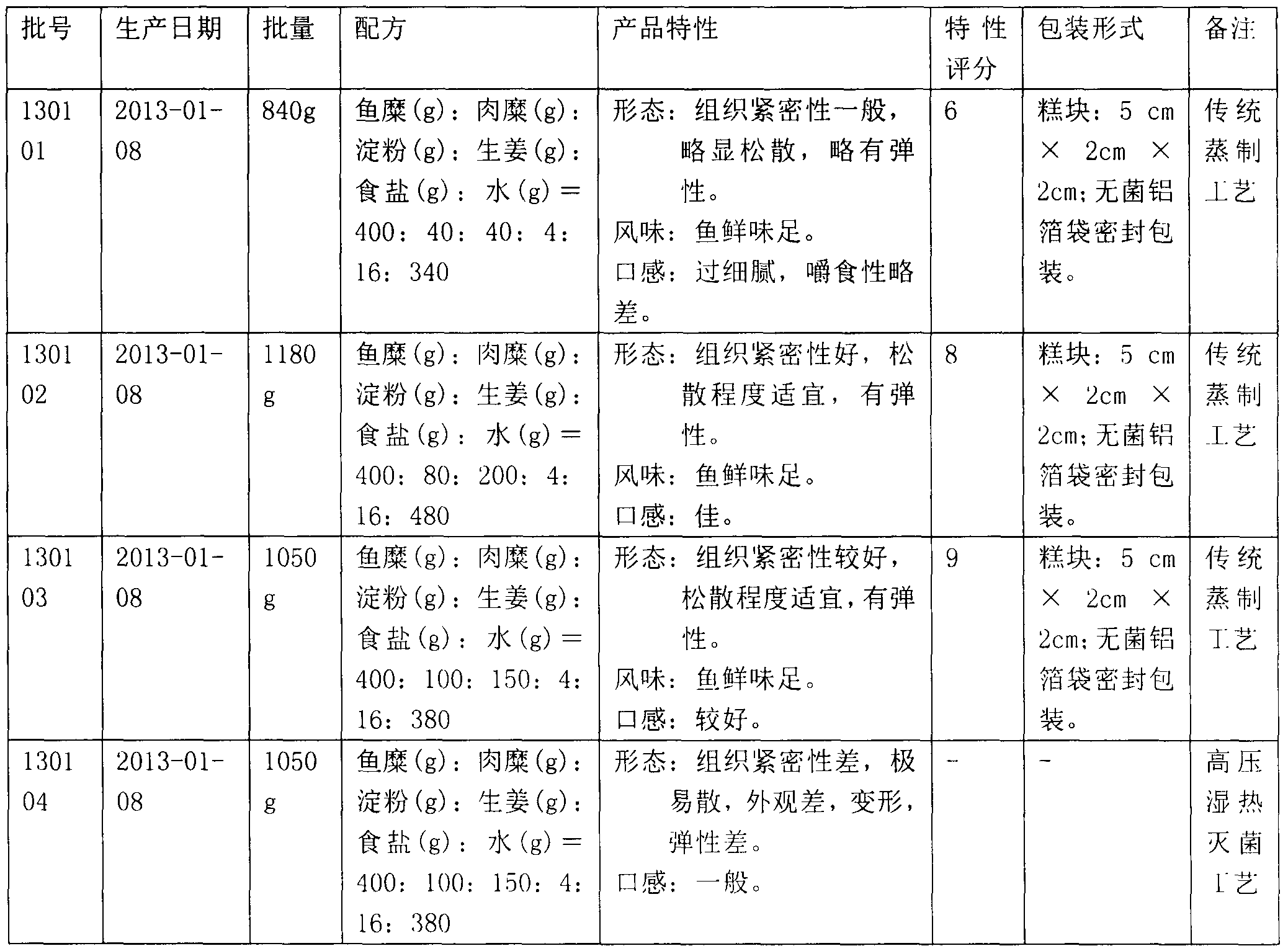

Examples

Embodiment 1

[0025] Embodiment 1 makes the local flavor fish cake that is main raw material with fish meat, pork

[0026] Proceed as follows:

[0027] (1) Take fresh silver carp, remove fish phosphorus with a phosphorus removal brush, cut open the belly of the fish with a stainless steel knife, remove internal organs and black film, rinse with clean water; peel the cleaned fish with a stainless steel knife, and remove the skin from the head to the bottom Next, separate the fish meat from the main thorn; the removed fish meat is crushed into surimi with a crushing machine, and the small bone spurs are finely filtered out with a fine filter (the diameter of the small hole in the screen is 2mm), and the surimi is smooth and non-grainy;

[0028] (2) Take 300 grams of pork, remove the bones and remove the skin, take 14 grams of ginger, mix it into the pork, grind it with a meat grinder, and make minced meat;

[0029] (3)) The minced fish and minced meat are batched and seasoned, mixed evenly, ...

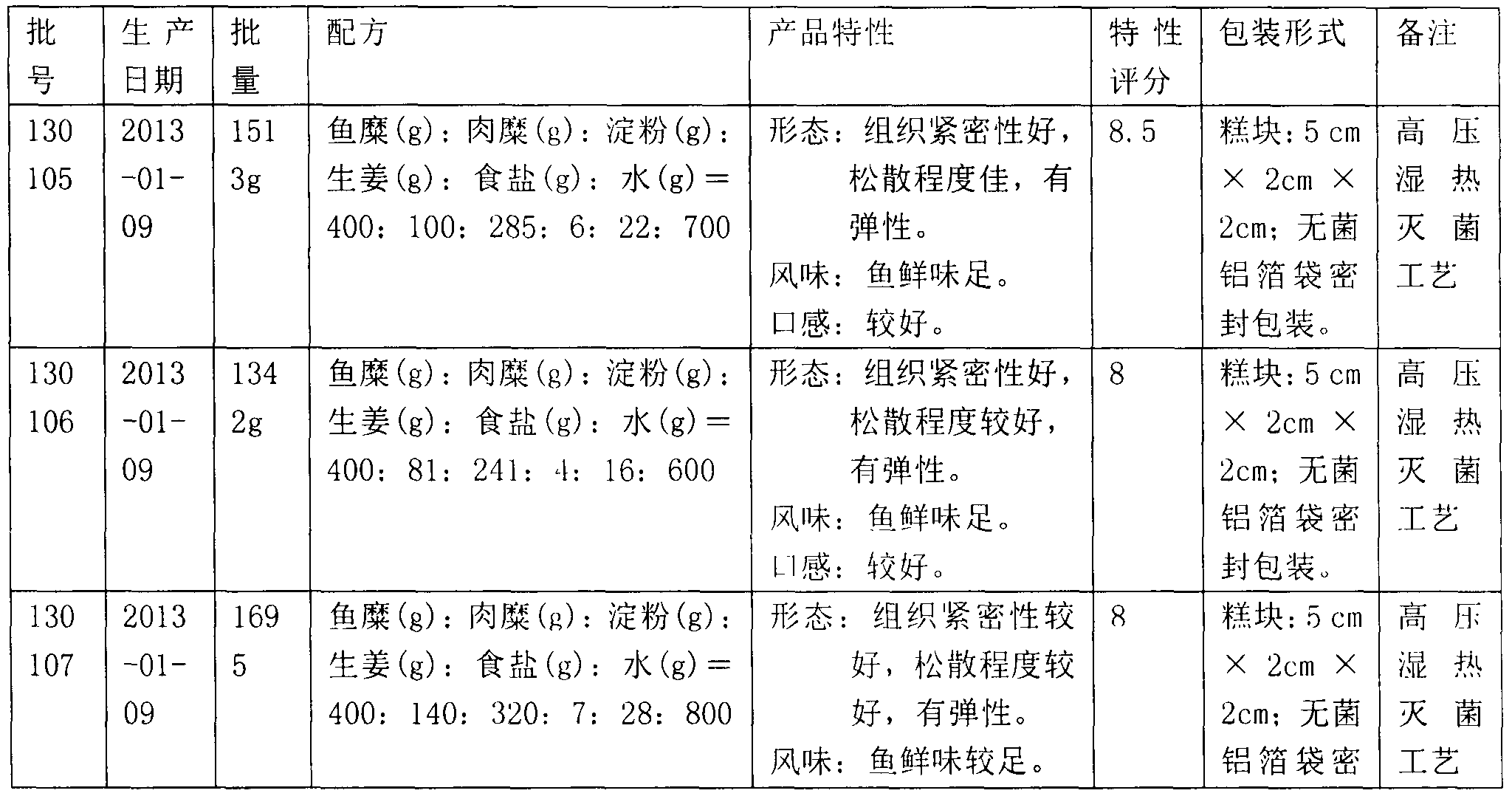

Embodiment 2

[0047] Embodiment 2 makes the flavor fish cake that is main raw material with fish meat, pork

[0048] The steps are the same as in Example 1, except that the ratio of main and auxiliary materials is as follows: 1000 grams of minced fish, 264 grams of minced meat, 15 grams of ginger, 700 grams of starch, 60 grams of egg white, 55 grams of salt, and 40 grams of mixed seasoning , 1800 grams of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com