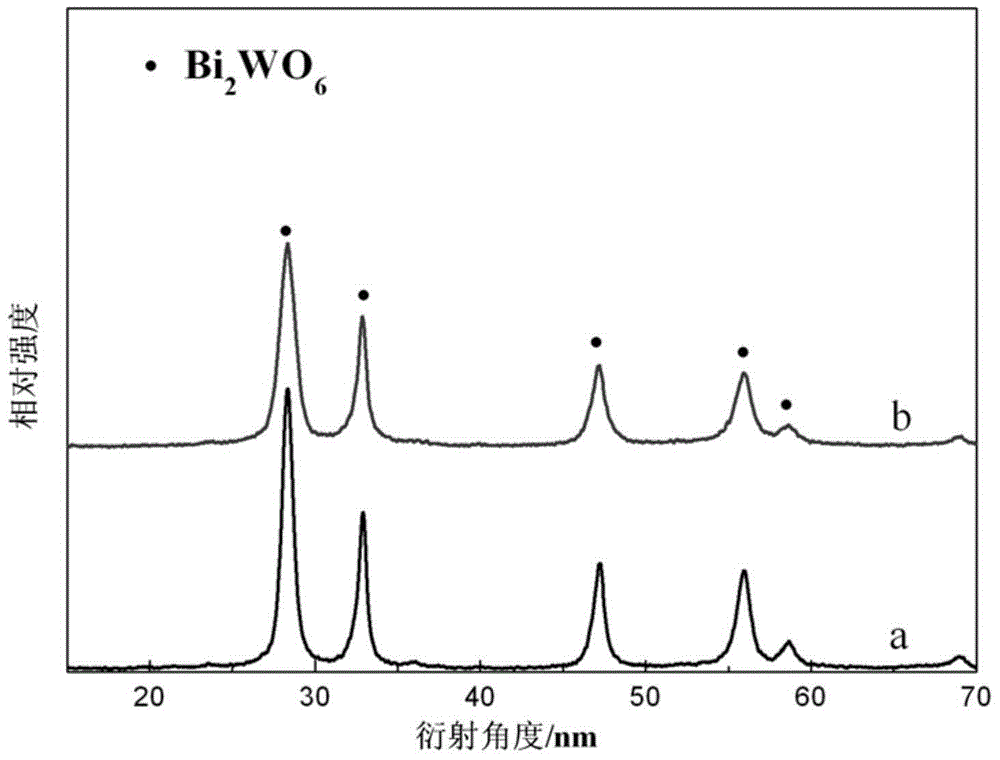

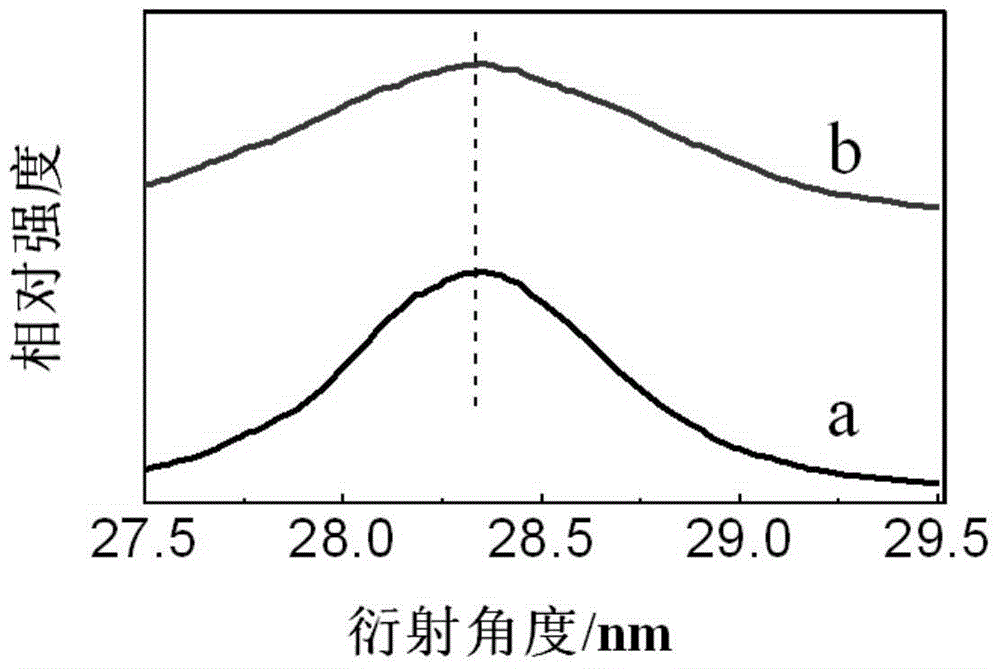

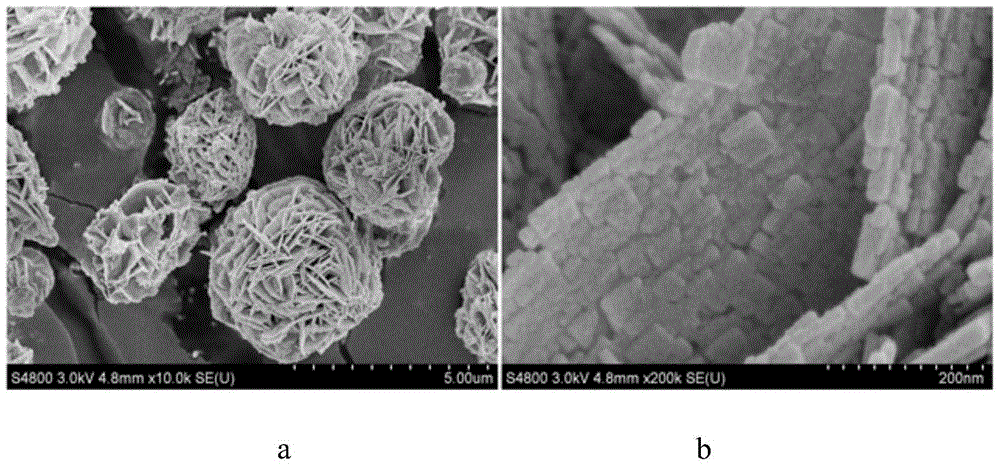

A kind of in-bi2wo6 photocatalyst with low electron-hole recombination rate and preparation method thereof

A technology of electron hole and photocatalyst, which is applied in the field of In-Bi2WO6 photocatalyst and its preparation, can solve the problems affecting the properties of synthetic powder, particle size, uneven heat distribution, slow heating rate, etc., and achieve uniform and stable morphology , short preparation cycle, fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In-Bi with low electron-hole recombination rate 2 WO 6 The preparation method of the photocatalyst includes the following steps:

[0032] Step 1: Weigh Bi(NO) according to the molar ratio of Bi:W=2:1 3 ) 3 ·5H 2 O and Na 2 WO 4 ·2H 2 Put O into the beaker, and weigh a certain amount of In(NO 3 ) 3 ·6H 2 O is added to the beaker, where the amount of In added x=2%, x=n In / (n Bi +n In )×100%, n Bi And n In Are the molar amounts of Bi and In respectively;

[0033] Step 2: Measure deionized water and add it to the beaker, stir fully at room temperature for 60 minutes until the raw materials are fully dissolved to form a white suspension, and prepare a mixed solution, in which Bi(NO 3 ) 3 ·5H 2 The concentration of O is 0.2mol / L, Na 2 WO 4 ·2H 2 The O concentration is 0.1 mol / L, and then ultrasonically oscillated for 30 minutes to obtain the precursor solution, and adjust the pH value of the precursor solution to 2.0;

[0034] Step 3: Transfer the precursor liquid into a microwave...

Embodiment 2

[0038] In-Bi with low electron-hole recombination rate 2 WO 6 The preparation method of the photocatalyst includes the following steps:

[0039] Step 1: Weigh Bi(NO) according to the molar ratio of Bi:W=2:1 3 ) 3 ·5H 2 O and Na 2 WO 4 ·2H 2 Put O into the beaker, and weigh a certain amount of In(NO 3 ) 3 ·6H 2 O was added to the beaker, the amount of In added x=10%, x=n In / (n Bi +n In )×100%, n Bi And n In Are the molar amounts of Bi and In respectively;

[0040] Step 2: Measure deionized water and add it to the beaker, stir fully at room temperature for 60 minutes until the raw materials are fully dissolved to form a white suspension, and prepare a mixed solution, in which Bi(NO 3 ) 3 ·5H 2 The concentration of O is 0.4mol / L, Na 2 WO 4 ·2H 2 The O concentration is 0.2mol / L, and then ultrasonically oscillated for 40 minutes to obtain the precursor solution, and adjust the pH value of the precursor solution to 1.8;

[0041] Step 3: Transfer the precursor liquid into a microwave hydr...

Embodiment 3

[0045] In-Bi with low electron-hole recombination rate 2 WO 6 The preparation method of the photocatalyst includes the following steps:

[0046] Step 1: Weigh Bi(NO) according to the molar ratio of Bi:W=2:1 3 ) 3 ·5H 2 O and Na 2 WO 4 ·2H 2 Put O into the beaker, and weigh a certain amount of In(NO 3 ) 3 ·6H 2 O is added to the beaker, where the amount of In added x=15%, x=n In / (n Bi +n In )×100%, n Bi And n In Are the molar amounts of Bi and In respectively;

[0047] Step 2: Measure deionized water and add it to the beaker, stir fully at room temperature for 60 minutes until the raw materials are fully dissolved to form a white suspension, and prepare a mixed solution, in which Bi(NO 3 ) 3 ·5H 2 The concentration of O is 0.1mol / L, Na 2 WO 4 ·2H 2 The concentration of O is 0.05mol / L, and then ultrasonically oscillate for 60 minutes to obtain the precursor solution, and adjust the pH of the precursor solution to 1.6;

[0048] Step 3: Transfer the precursor liquid into a microwave hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com