A kind of magnesium alloy anti-gravity casting device and method thereof

A technology of anti-gravity casting and magnesium alloys, applied in the field of casting, can solve the problems of easy combustion or oxidation of magnesium alloys, and achieve the effects of preventing oxidation slag inclusion defects, good performance, and improving surface quality and internal structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

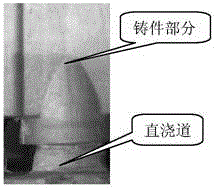

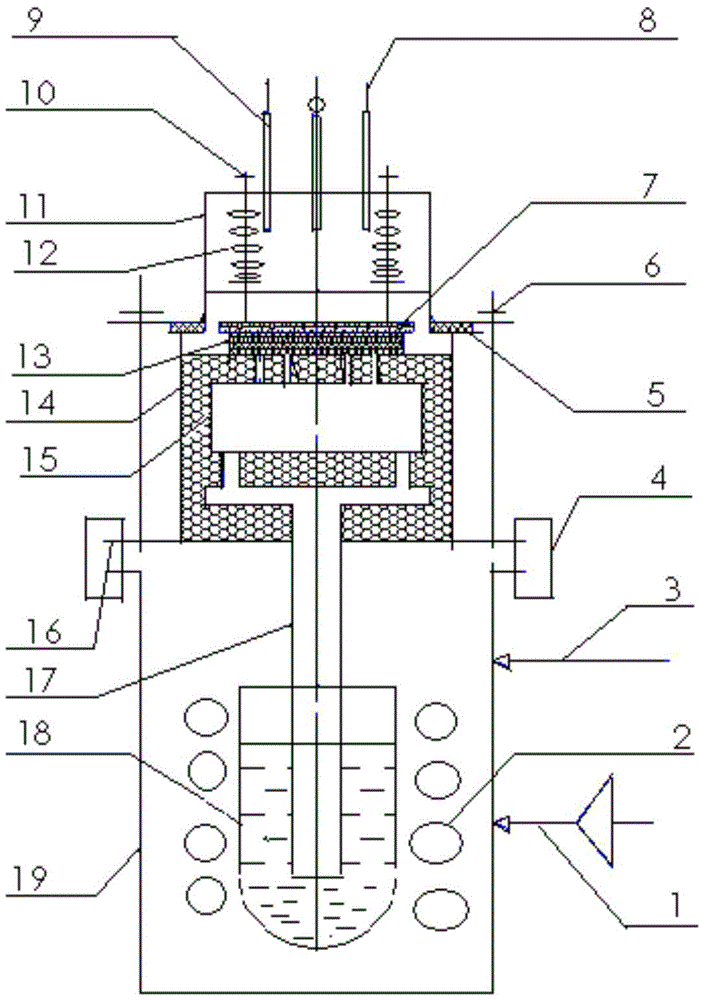

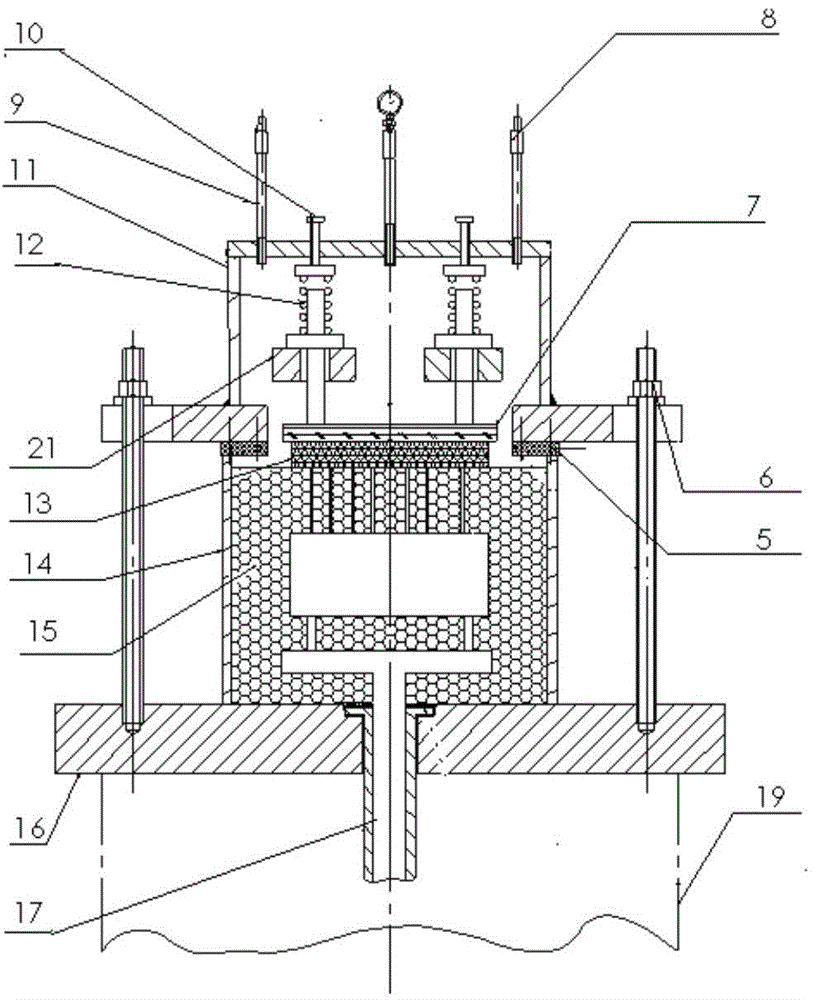

[0036] Such as figure 1As shown, this embodiment describes a magnesium alloy anti-gravity casting device, which includes: a melting furnace 2 and a crucible 18 built in a lower tank 19 , and the upper part of the lower tank 19 is isolated from the outside by a sealing cover 16 . In order to prevent the magnesium alloy melt from burning with oxygen, between the melting furnace 2 and the sealing cover plate 16 , the lower tank 19 is connected to the first protective gas pipeline 3 . In this way, the mixed gas of 1-10% sulfur hexafluoride and 90-99% argon injected through the first shielding gas pipeline 3, the sulfur hexafluoride with a larger proportion can float on the magnesium alloy melt, and react with the magnesium alloy The melt reacts to form a surface film with different protective effects on the surface of the magnesium alloy melt. The surface film is dense, which can not only isolate the magnesium alloy melt from the air, prevent the reaction from continuing, but also...

Embodiment 2

[0045] This embodiment describes a casting method using the device described in the above embodiments, the method includes the following steps:

[0046] Step 1. Put the magnesium alloy into a melting furnace at 730° C. to 820° C. for smelting and removing slag, and at the same time, heat the gypsum mold at 200° C. to 400° C. ;

[0047] Step 2. Put the molten magnesium alloy after smelting and deslagging into the crucible, seal the lower tank with a sealing cover, seal the contact surface between the riser and the sealing cover with asbestos, and lock the The sealing cover plate is locked with the lower tank.

[0048] Step 3. Place the heated plaster mold directly on the sealing cover, align the gate with the upper port of the riser, and use asbestos to seal the plaster mold, and then turn the negative pressure The gas protection box is directly placed on the plaster mold and fixedly connected with the sealing cover plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile properties | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com