Polycarboxylate water reducer prepared by taking novel polyether as raw material, and preparation and application method thereof

A technology of polycarboxylic acid series and water reducing agent, which is applied in the field of preparation of polycarboxylic acid series water reducing agent and polycarboxylic acid series water reducing agent, can solve problems such as poor slump retention, and achieve good slump retention and convenient operation. , the effect of high water reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]Prepare the high performance polycarboxylate water reducer of the present invention according to the following steps:

[0039] (1) Preparation before polymerization: Accurately weigh 135 parts by weight of water for use in the following steps;

[0040] Preparation of solution A: Accurately weigh 10 parts by weight of acrylic acid, 1.80 parts by weight of methacrylic acid, 0 parts by weight of sodium methacrylate sulfonate and 36 parts by weight of water, stir and mix evenly, pump into the high level tank A, and prepare dropwise;

[0041] Preparation of solution B: Accurately weigh 0.25 parts by weight of L-ascorbic acid, 0.90 parts by weight of mercaptoacetic acid, 0.15 parts by weight of mercaptopropionic acid and 48 parts by weight of water, stir and mix evenly, pump into the high level tank B, and prepare dropwise;

[0042] Preparation of mixture C: Accurately weigh 100 parts by weight of new polyether DD-507 with a number average molecular weight of 1200, 0.75 parts ...

Embodiment 2~ Embodiment 5

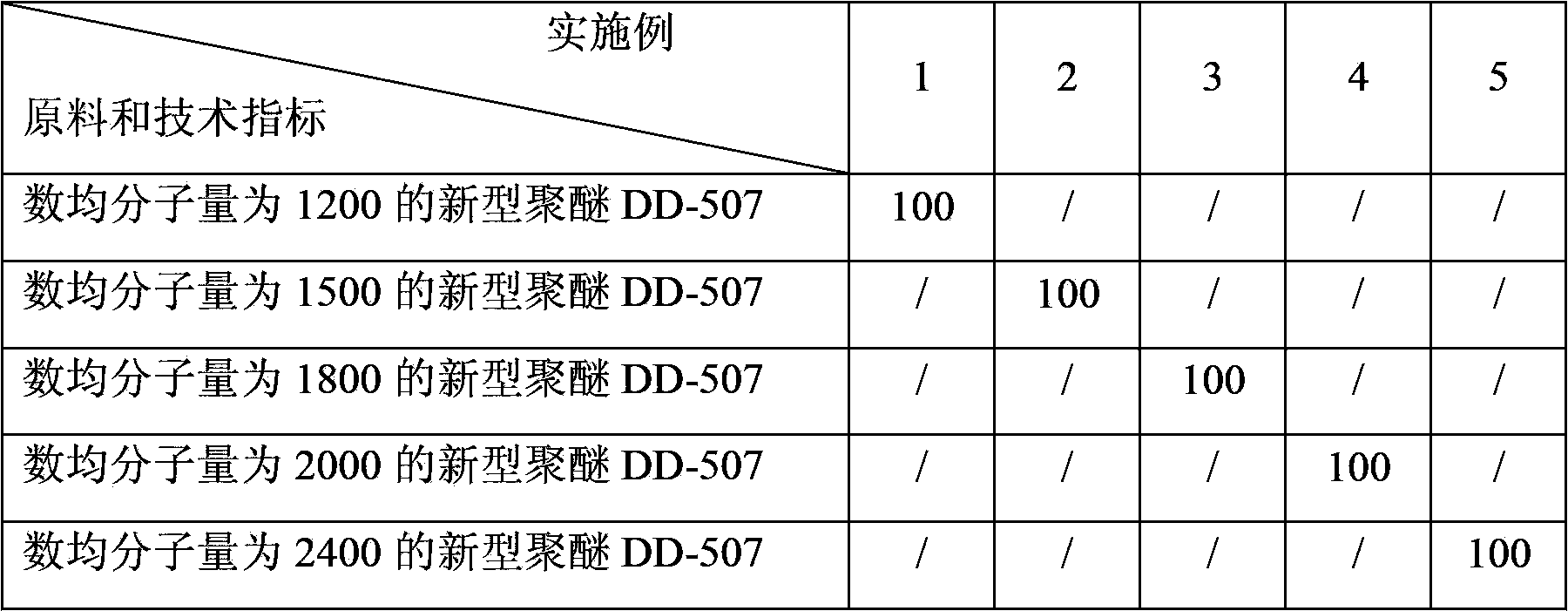

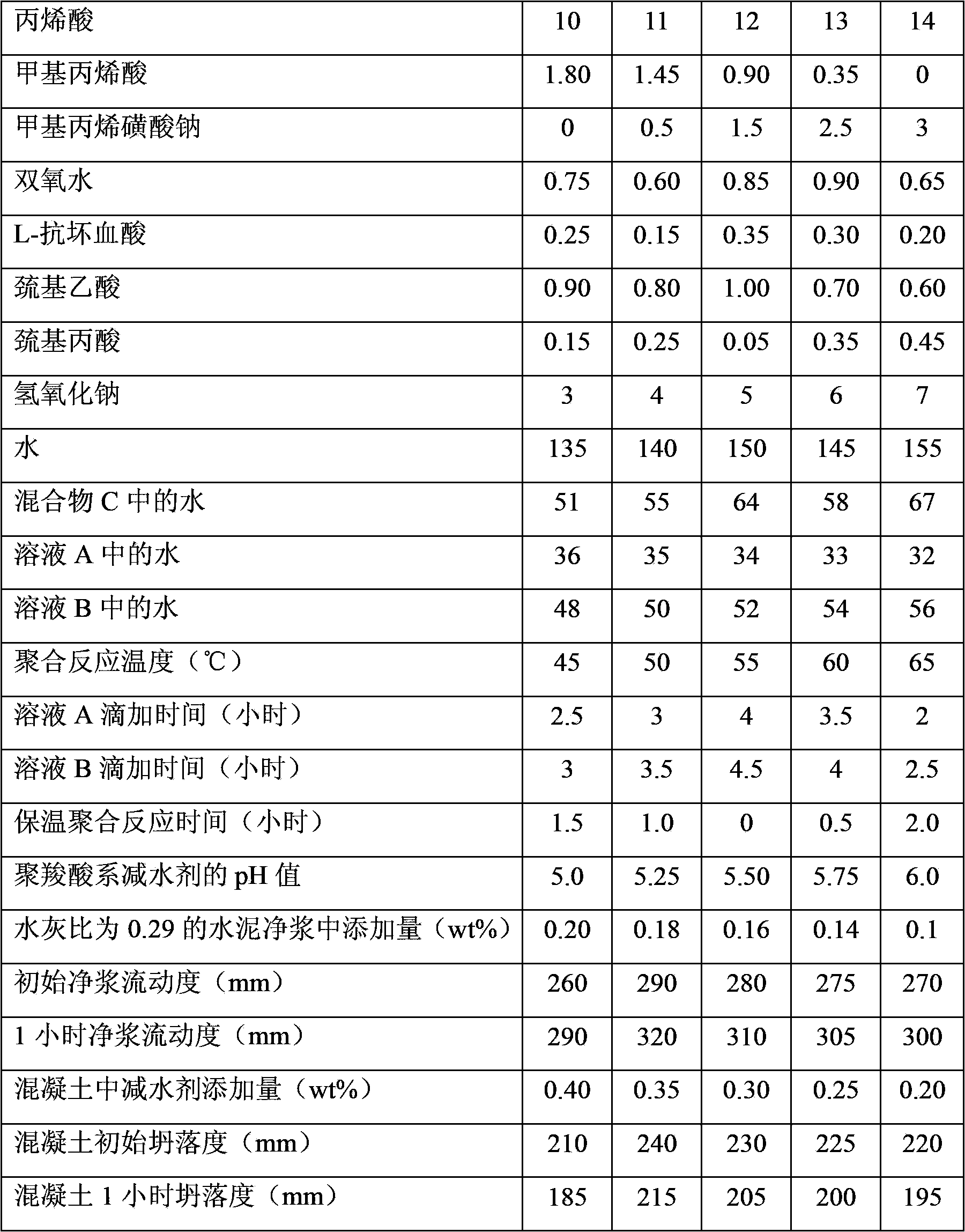

[0049] According to the method and steps of Example 1, prepare the polycarboxylate water reducer of the present invention according to the formula in Table 1, and add the obtained polycarboxylate water reducer to the cement paste according to the addition amount shown in Table 1 And in concrete, the performance data of gained cement slurry and concrete are also shown in Table 1.

[0050] Table 1 (the dosage units of each component are parts by weight)

[0051]

[0052]

[0053] It can be seen from Table 1 that the polycarboxylate water reducer of the present invention has good water reducing rate and slump retention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com