Photochromic powder, photochromic film, photochromic glass and preparation method thereof

A photochromic glass and photochromic technology, applied in chemical instruments and methods, glass/slag layered products, adhesives, etc., can solve problems such as poor discoloration performance, achieve improved discoloration performance, low cost, and good discoloration performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

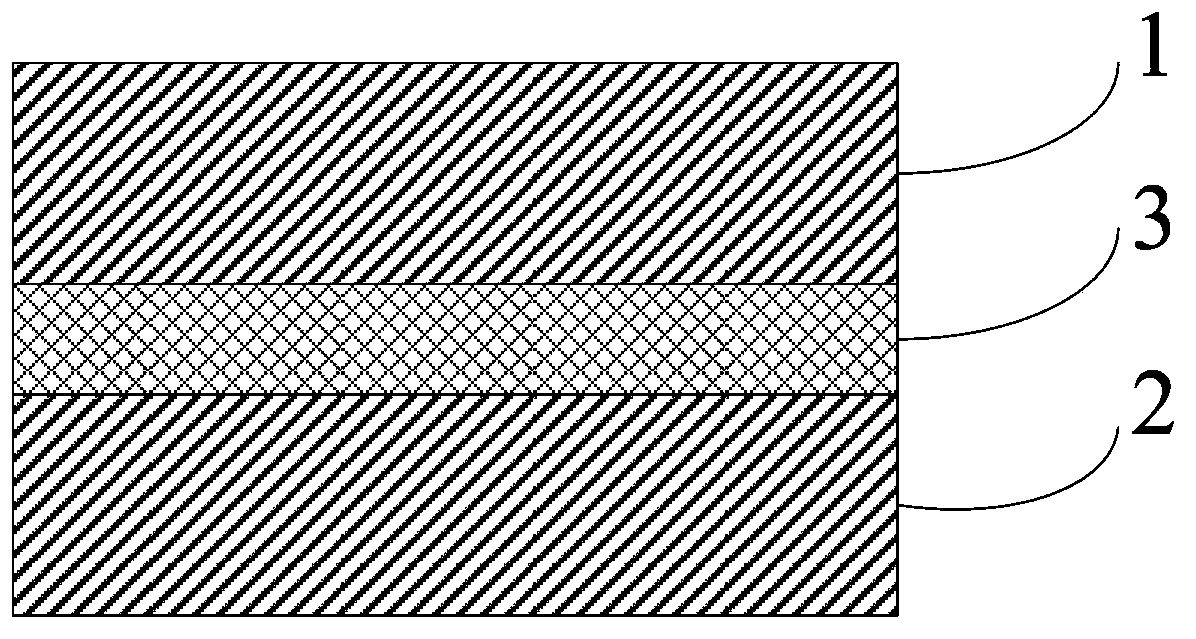

[0037] Specifically, the photochromic film preparation method includes the following steps:

[0038]Provide polyvinyl butyral, plasticizer, coupling agent and the above-mentioned photochromic powder, the photochromic powder, polyvinyl butyral, plasticizer and coupling agent according to the following weight percentage Mix to obtain a mixture, put the mixture into a mixer and stir for 10-20 minutes, heat to 140-160°C to melt and extrude to make a film of 0.38-3.04 mm, and then cool, remove water, blow dry, etc. Afterwards, obtain photochromic film; The weight percent of each component is as follows:

[0039]

[0040] Specifically, the polyvinyl butyral, plasticizer, coupling agent and photochromic powder are the same as those described above, and will not be repeated here.

[0041] The photochromic film of the embodiment of the present invention has a better color changing effect by selecting the above photochromic powder.

[0042] The embodiment of the present invention a...

Embodiment 1

[0056] The preparation method of the photochromic glass of this embodiment comprises the following steps:

[0057] The first step is to prepare inorganic photochromic powder:

[0058] Weigh 80 parts by weight of tungsten oxide, 10 parts by weight of titanium oxide, 5 parts by weight of zinc oxide and 20 parts by weight of oxalic acid, after mixing evenly, transfer the material to a high-energy ball mill and grind and dope for 2 hours to make these powders The particle size reaches micron and nanometer levels, and makes various material particles closely bonded to each other by intermolecular force, resulting in WO 3 -H 2 C 2 o 4 -TiO 2 - ZnO inorganic photochromic powder;

[0059] The second step is to prepare PVB photochromic film:

[0060] Take 1 part by weight of WO 3 -H 2 C 2 o 4 -TiO 2 -ZnO inorganic photochromic powder, 1 weight part of triethylene glycol di-n-heptanoate plasticizer, 0.8 weight part of coupling agent select vinyl triethoxysilane and 97.2 weigh...

Embodiment 2

[0065] The preparation method of the photochromic glass of this embodiment comprises the following steps:

[0066] The first step is to prepare inorganic photochromic powder:

[0067] Weigh 40 parts by weight of tungsten oxide, 5 parts by weight of titanium oxide, 3 parts by weight of zinc oxide and 15 parts by weight of oxalic acid, after mixing evenly, transfer the material to a high-energy ball mill and grind and dope for 3 hours to make these powders The particle size reaches micron and nanometer levels, and makes various material particles closely bonded to each other by intermolecular force, resulting in WO 3 -H 2 C 2 o 4 -TiO 2 - ZnO inorganic photochromic powder;

[0068] The second step is to prepare PVB photochromic film:

[0069] Take 2 parts by weight of WO 3 -H 2 C 2 o 4 -TiO 2 -ZnO inorganic photochromic powder, 1.5 parts by weight of triethylene glycol di-n-heptanoate plasticizer, 0.9 parts by weight of coupling agent select vinyl triethoxysilane and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com