Workpiece surface intensifying method by laser micro processing

A workpiece surface and micro-processing technology, which is applied in the field of laser strengthening treatment of the workpiece surface, can solve the problems of low hardness and wear resistance, hinder cracks, etc., and achieve improved wear resistance, small heat-affected zone, quenching stress and deformation small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

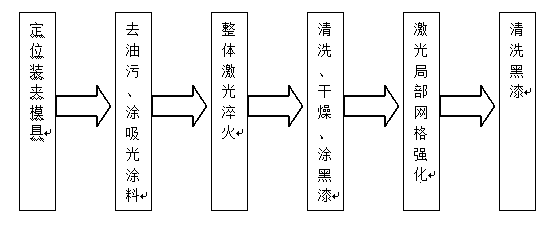

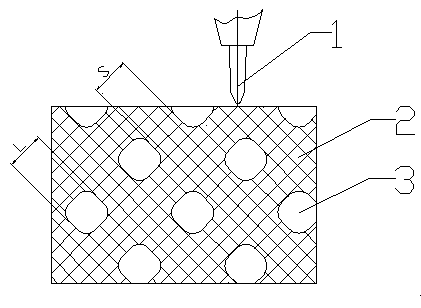

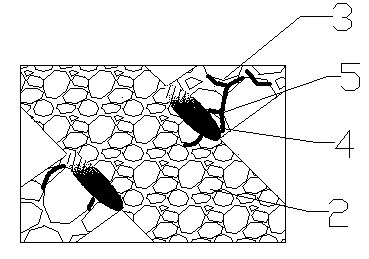

[0024] like figure 1 and figure 2 As shown, the 45# steel automotive LED headlight workpiece. Place the workpiece on the five-axis linkage workbench, position it and clamp it with a fixture device: use alcohol degreasing and decontamination solvent to remove oil and rust on the surface of the workpiece; use a spray gun or brush to evenly coat SiO2 light-absorbing paint on the surface of the workpiece Above; adjust the parameters (laser power, scanning speed) and spot diameter of laser 1, where the laser energy emitted by laser 1 is 800w, the scanning speed is 7mm / s, the spot diameter is 10mm, and the overlap rate is 70%, which is good for the workpiece surface Carry out overall quenching; clean the surface of the workpiece and apply black paint after drying; adjust the parameters of laser 4 (laser power, scanning speed) and spot diameter, where the laser energy emitted by laser 1 is 20J, the pulse width is 50ns, and the spot diameter is 3mm. The connection rate is 50%, K9 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com