Cubic γ′ Nanoparticle Coherent Precipitation Strengthened Superalloy with Stable Structure at 900°C and Preparation Method

A nanoparticle and superalloy technology, applied in the field of Co-based superalloys, can solve the problems of deteriorating the mechanical properties of the alloy, destroying the coherent relationship, large lattice distortion, etc., achieving excellent oxidation resistance, improving mechanical properties, high-temperature microstructure The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

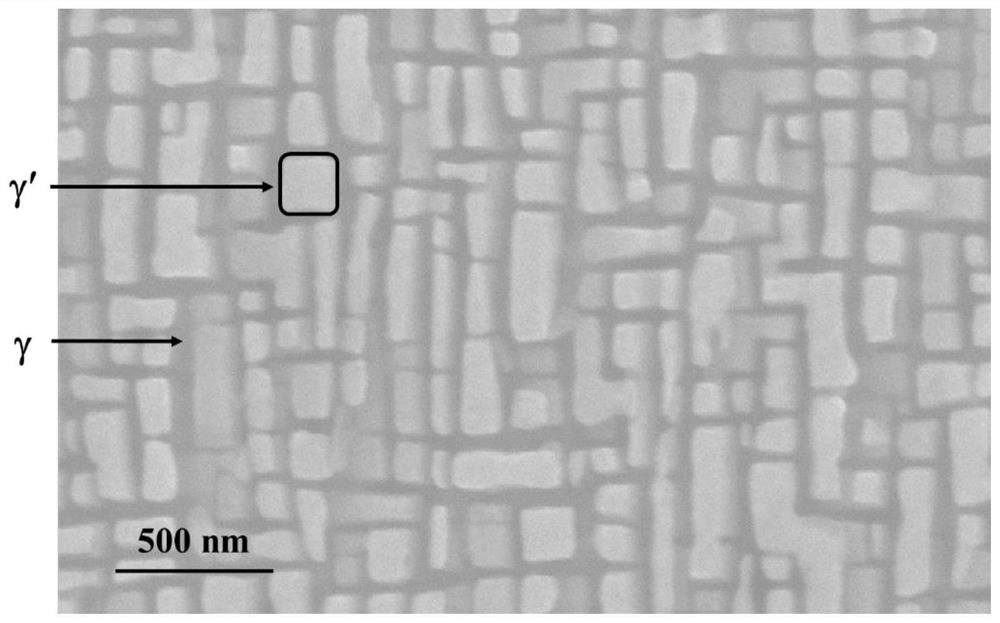

[0020] Embodiment 1: Co-22.6Ni-2.6Al-17.7W-1.5Ti-0.7Nb-1.5Ta-2.5Cr (wt.%) alloy

[0021] Step 1: Alloy Preparation

[0022] High-purity metal materials are used, and ingredients are prepared according to mass percentage. The ingredients are smelted at least four times in a vacuum non-consumable arc melting furnace under the protection of an argon atmosphere to obtain an alloy ingot with a uniform composition and a mass of about 120 g, and the mass loss during the smelting process does not exceed 0.1%. The alloy ingot is subjected to solution treatment at 1300°C / 15h in a muffle furnace, water quenching, and the purpose of solution treatment is to reduce or eliminate the composition segregation of the structure and dissolve the inhomogeneous precipitated phase; followed by 500h at 900°C Aging treatment, water quenching.

[0023] Step 2: Alloy structure and mechanical properties test

[0024] Using OM, SEM and XRD to detect the microstructure and structure of the alloy after a...

Embodiment 2

[0025] Embodiment 2: Co-28.2Ni-2.6Al-17.7W-1.5Ti-0.7Nb-1.5Ta-2.5Cr (wt.%) alloy

[0026] Step 1: Alloy Preparation

[0027] High-purity metal materials are used, and ingredients are prepared according to mass percentage. The ingredients are smelted at least four times in a vacuum non-consumable arc melting furnace under the protection of an argon atmosphere to obtain an alloy ingot with a uniform composition and a mass of about 120 g, and the mass loss during the smelting process does not exceed 0.1%. The alloy ingot is subjected to solution treatment at 1300°C / 15h in a muffle furnace, water quenching, and the purpose of solution treatment is to reduce or eliminate the composition segregation of the structure and dissolve the inhomogeneous precipitated phase; followed by 10h at 900°C Aging treatment, water quenching.

[0028] Step 2: Alloy structure and mechanical properties test

[0029] Utilize OM, SEM and XRD to detect the microstructure and structure of the alloy after ...

Embodiment 3

[0030] Embodiment 3: Co-22.6Ni-2.6Al-17.7W-1.5Ti-0.8Nb-1.5Ta-5.1Cr (wt.%) alloy

[0031] Step 1: Alloy Preparation

[0032] Use high-purity metal materials, and carry out batching according to mass percentage. The ingredients are smelted at least four times in a vacuum non-consumable arc melting furnace under the protection of an argon atmosphere to obtain an alloy ingot with a uniform composition and a mass of about 120 g, and the mass loss during the smelting process does not exceed 0.1%. The alloy ingot is subjected to solution treatment at 1300°C / 15h in a muffle furnace, water quenching, and the purpose of solution treatment is to reduce or eliminate the composition segregation of the structure and dissolve the inhomogeneous precipitated phase; followed by 100h at 900°C Aging treatment, water quenching.

[0033] Step 2: Alloy structure, mechanical properties and corrosion resistance test

[0034] Utilize OM, SEM and XRD to detect the microstructure and structure of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com