Er-containing high-strength high-plasticity heat-resistant magnesium alloy and preparation method thereof

A magnesium alloy, high-plasticity technology, applied in the field of alloy materials, can solve the problems of reducing alloy plasticity and aggravating dislocation accumulation, so as to achieve the effect of improving strength, improving mechanical properties and hindering dislocation slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the high-strength and high-plastic heat-resistant magnesium alloy containing Er of the present invention comprises the following steps:

[0031] a. Material selection: select raw materials according to the weight percentage of elements, the raw materials are industrial pure magnesium ingots, industrial pure zinc, Mg-30Y (wt.%) master alloy, Mg-30Er (wt.%) master alloy and Mg- 30Zr (wt.%) master alloy;

[0032] b. Smelting: Weigh the raw materials according to the elemental composition of the invented Er-containing high-strength, high-plasticity heat-resistant magnesium alloy, melt them under vacuum or protective atmosphere conditions, and then cast them into castings;

[0033] c. Homogenization treatment: homogenize the casting at 500-550° C. for 10-12 hours;

[0034] d. Extrusion deformation: Extrude and deform the homogenized casting at an extrusion temperature of 350-400°C, an extrusion ratio of 33-35, and an extrusion speed of 0.1-0.3mm / s,...

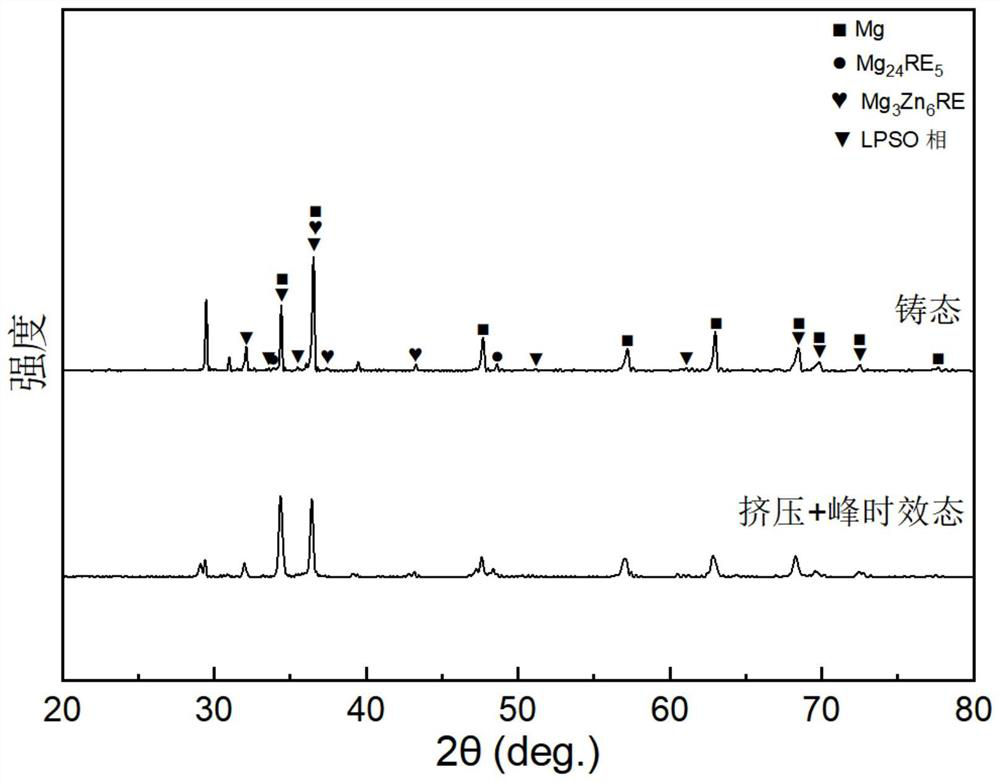

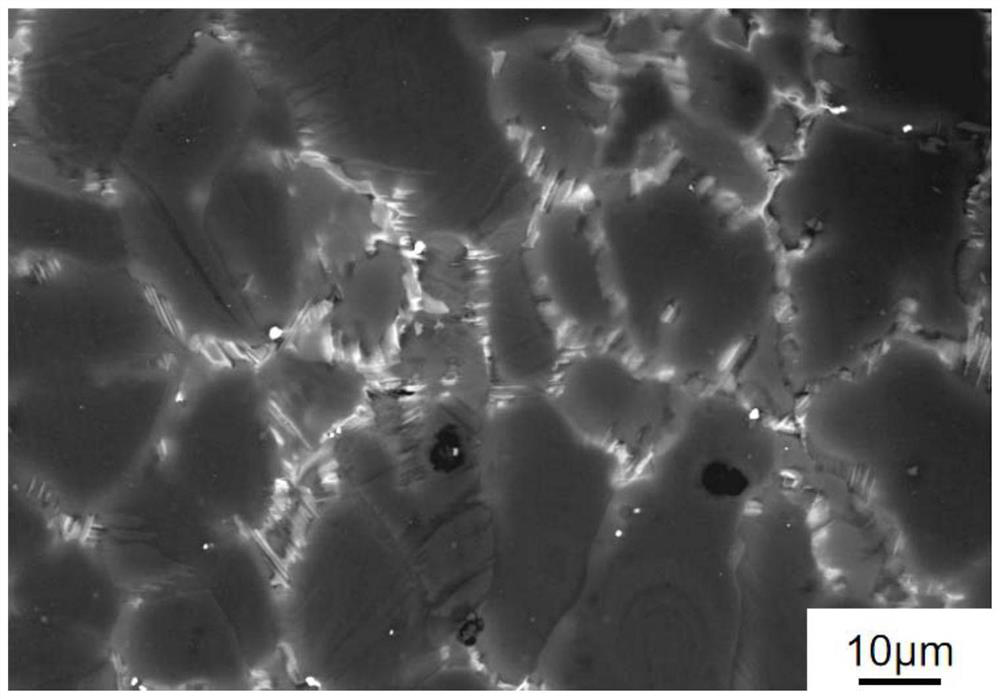

Embodiment 1

[0039] The Er-containing high-strength and high-plasticity heat-resistant magnesium alloy in this embodiment includes the following components in terms of element weight percentage: 9.0% Er, 4.0% Y, 0.5% Zn, 0.5% Zr, and the rest is Mg.

[0040] The preparation process of the high-strength and high-plastic heat-resistant magnesium alloy containing Er in this embodiment is as follows:

[0041] In the high-frequency electromagnetic induction melting furnace, pure Mg block (99.9wt.%) is added, the furnace temperature rises to 750±5°C and SF 6 :CO 2 The protective gas with a volume ratio of 1:200, after the magnesium block is completely melted, skim off the scum on the surface of the melt, and then add pure Zn (99.9wt.%), Mg-30Y (wt.%) master alloy, Mg- 30Er (wt.%) master alloy, after all melting, when the furnace temperature rises to 780±5°C, add Mg-30Zr(wt.%) master alloy, and then remove the slag on the melt surface and the crucible wall. After the intermediate alloy is compl...

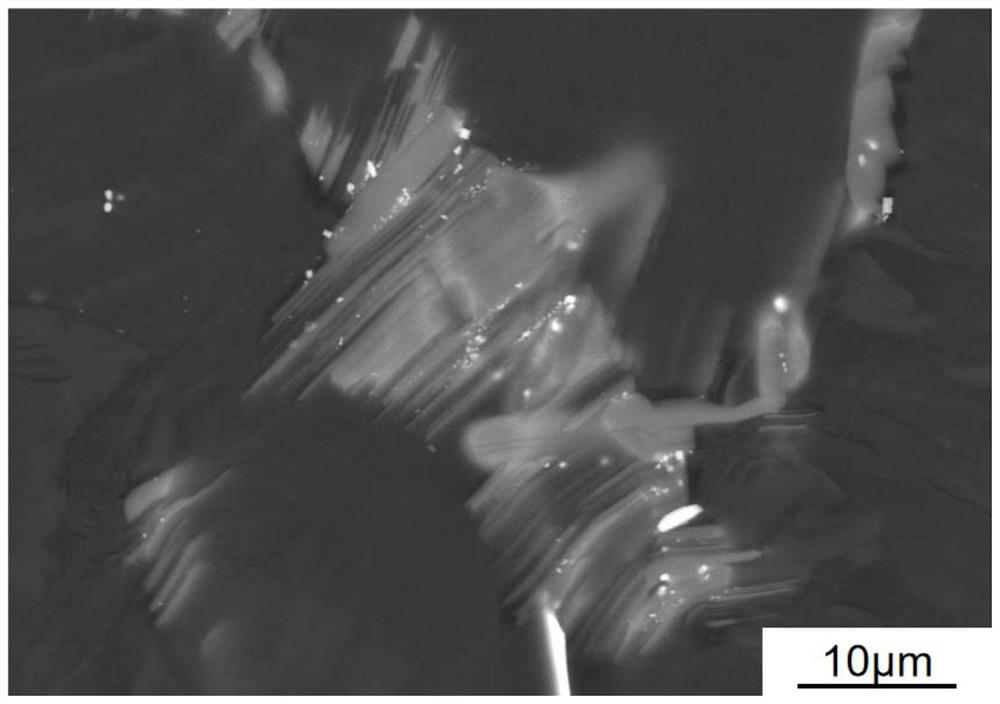

Embodiment 2

[0046] The Er-containing high-strength and high-plasticity heat-resistant magnesium alloy in this embodiment includes the following components by weight percentage of elements: 8.9% Er, 4.0% Y, 0.6% Zn, 0.4% Zr, and the rest is Mg.

[0047] The preparation process of the high-strength and high-plastic heat-resistant magnesium alloy containing Er in this embodiment is as follows:

[0048] In the high-frequency electromagnetic induction melting furnace, add pure Mg block (99.9wt.%), the furnace temperature rises to 750 ° C ± 5 and SF 6 :CO 2 Protective gas with a volume ratio of 1:200. After the magnesium block is completely melted, skim off the scum on the surface of the melt, and then add pure Zn (99.9wt.%), Mg-30Y (wt.%) master alloy, Mg-30Er (wt.%) master alloy, after all melting, when the furnace temperature rises to 780±5°C, add Mg-30Zr(wt.%) master alloy, and then remove the molten slag on the surface of the melt and the crucible wall. After the intermediate alloy is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com