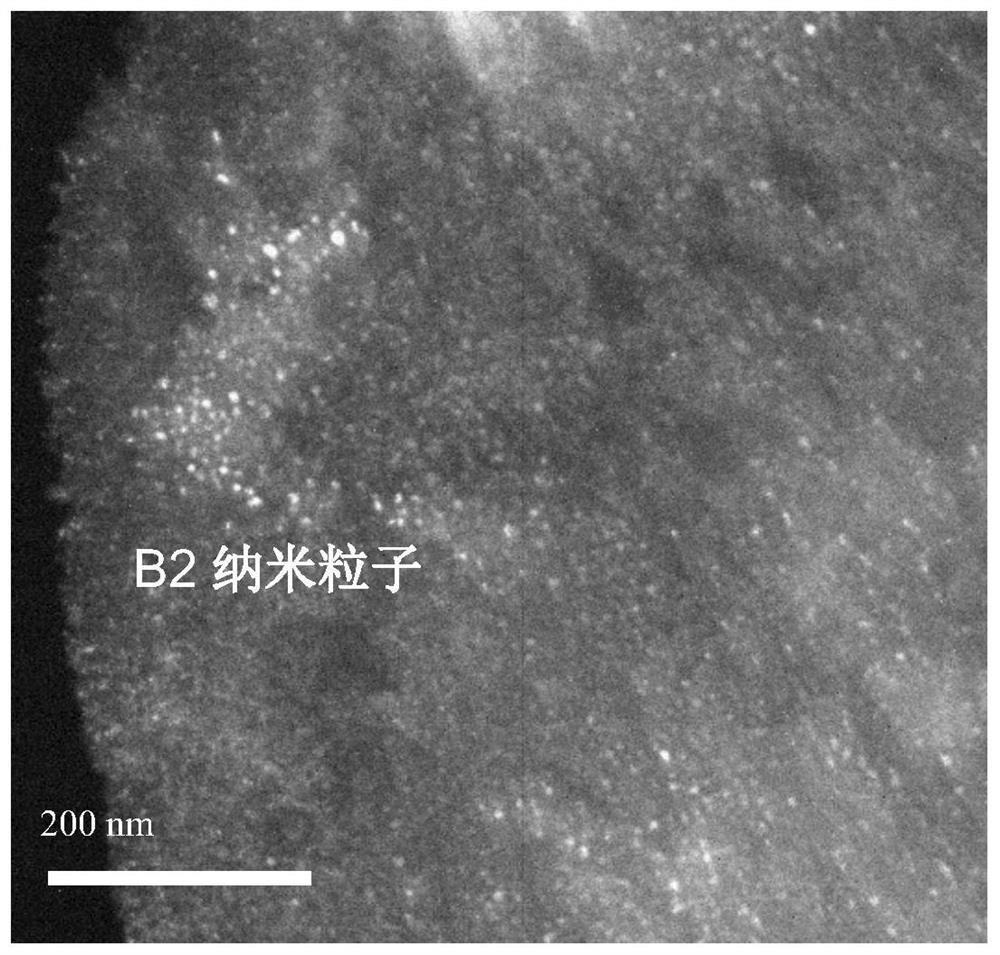

An ultra-high-strength maraging stainless steel strengthened by b2 nanoparticle coherent precipitation and its preparation method

An ultra-high-strength, nano-particle technology, applied in the field of high-strength stainless steel, can solve the problems of reduced strength, increased brittleness, and unsatisfactory ultra-high strength of maraging steel, etc., to achieve material cost reduction, good plastic toughness, and improved uniformity Effect of Plastic Deformability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Fe-5.30 CR-13.47NI-3.10Al-1.22Mo-0.50W-0.23NB-0.03C-0.005B (wt.%) Alloy

[0021] Step 1: Alloy preparation

[0022] High-purity metal materials are used for ingredients according to quality percent. The ingredients were repeatedly repeatedly repeated by a vacuum non-power consuming arc melting furnace under argon atmosphere to obtain a co-hemor with a uniform mass of about 100 g, and the mass loss in the smelting process does not exceed 0.1%. The homogenization treatment of 1250 ° C / 2H was carried out with a muffle furnace. Subsequently, multiple cold rolling, the pressure is not more than 0.2 mm per second, with a total deformation amount of about 70% to give a plate sample having a thickness of about 3 mm. The annealing treatment of 950 ° C / 15 min was then subjected to a time limit of 500 ° C / 8 h.

[0023] Step 2: Alloy tissue structure and mechanical properties and corrosion resistance test

[0024] The alloy tissue and structure after the stabilization ...

Embodiment 2

[0025] Example 2: Fe-4.0Cr-15.0 Ni-3Al-1MO-0.70W-0.2NB-0.03C-0.004B (wt.%) Alloy

[0026] Step 1: Alloy preparation

[0027] High-purity metal materials are used for ingredients according to quality percent. The ingredients were repeatedly repeatedly repeated by a vacuum non-power consuming arc melting furnace under argon atmosphere to obtain a co-hemor with a uniform mass of about 100 g, and the mass loss in the smelting process does not exceed 0.1%. The homogenization treatment of 1250 ° C / 2H was carried out with a muffle furnace. Subsequently, multiple cold rolling, the pressure is not more than 0.2 mm per second, with a total deformation amount of about 70% to give a plate sample having a thickness of about 3 mm. The annealing treatment of 950 ° C / 15 min was then subjected to a time limit of 500 ° C / 12 h.

[0028] Step 2: Alloy organizational structure and mechanical performance test

[0029] With OM, SEM, and XRD detection, the alloy tissue and structure showed that the...

Embodiment 3

[0030] Example 3: Fe-6.0Cr-13.0 Ni-4.0Al-2.0Mo-0.50W-0.40NB-0.05C-0.008B (wt.%) Alloy

[0031] Step 1: Alloy preparation

[0032] Using a high-purity metal, ingredients are performed according to the percentage of mass. The ingredients were repeatedly repeatedly repeated by a vacuum non-power consuming arc melting furnace under argon atmosphere to obtain a co-hemor with a uniform mass of about 100 g, and the mass loss in the smelting process does not exceed 0.1%. The homogenization treatment of 1250 ° C / 2H was carried out with a muffle furnace. Subsequently, multiple cold rolling, the pressure is not more than 0.2 mm per second, with a total deformation amount of about 70% to give a plate sample having a thickness of about 3 mm. The annealing treatment of 950 ° C / 15 min was subsequently carried out, and the aging of 500 ° C / 48 h was finalized.

[0033] Step 2: Alloy tissue structure and mechanical properties and corrosion resistance test

[0034] With OM, SEM, and XRD detect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com