InGaN/GaN superlattice buffer layer structure, preparation method of InGaN/GaN superlattice buffer layer structure, and LED chip comprising InGaN/GaN superlattice buffer layer structure

An LED chip and buffer layer technology, applied in the field of multiple quantum wells, can solve the problems of large MQW layer stress in the LED chip, low luminous efficiency of the LED chip, and many crystal defects, so as to improve crystal quality, reduce electron leakage, and improve luminescence. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

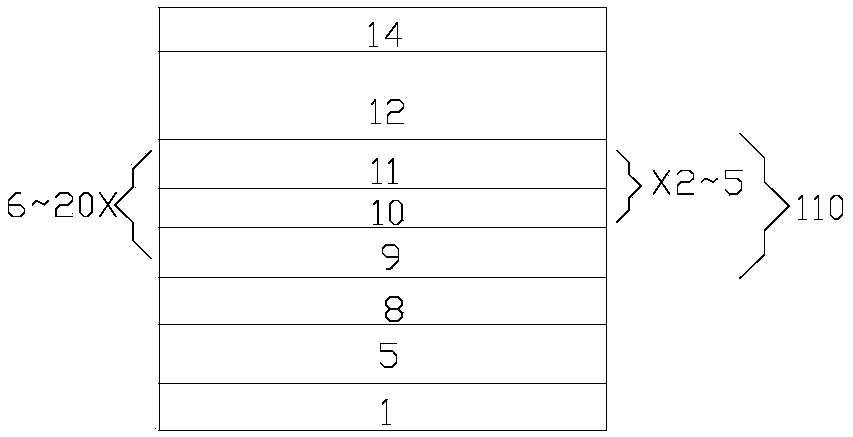

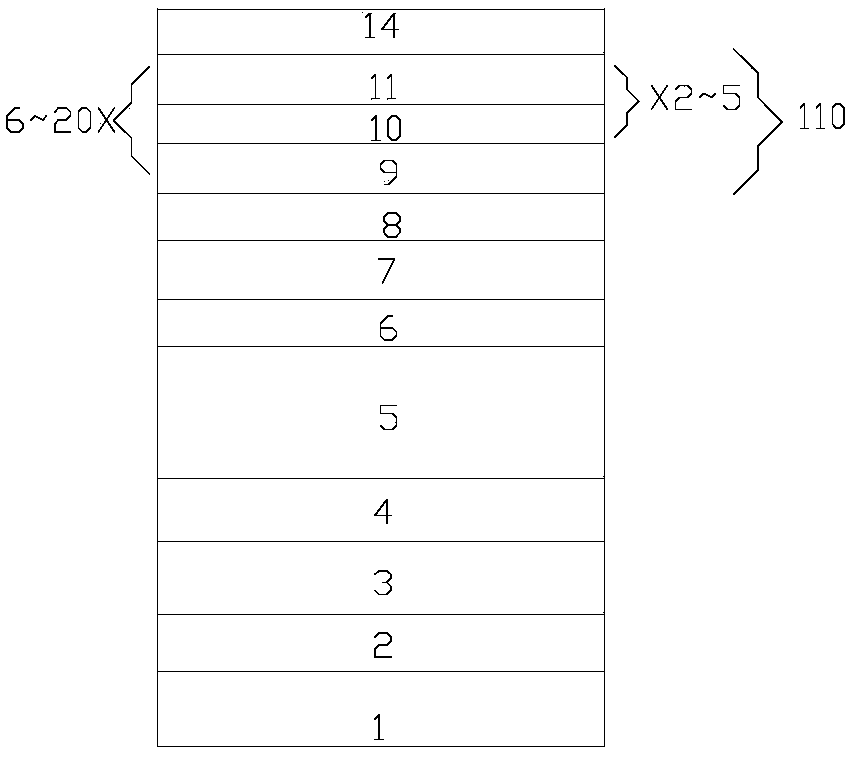

[0047] See structure image 3 .

[0048] 1. Place the sapphire substrate 1 in the MOCVD reaction chamber, and use H 2 , NH 3 Treat the sapphire substrate 1 with the gas at high temperature for 4 to 10 minutes;

[0049] 2. After the treatment is completed, the temperature of the reaction chamber is lowered to 500-550°C, and TMGa and NH 3 , with a pressure of 300-900 mbar, growing a low-temperature first GaN buffer layer 2 (Nucleation) with a thickness of 20-50 nm on the sapphire substrate 1;

[0050] 3. After the first GaN buffer layer 2 is grown, the temperature is raised to 950-1050°C, and the temperature is annealed at a high temperature for 60-300s to form a GaN crystal nucleus on the substrate 1;

[0051] 4. After the high-temperature annealing is completed, the temperature is adjusted to 960-1020°C, and TMGa and NH 3 , the pressure is controlled at 300-900mbar, and a high-temperature non-doped first uGaN layer 3 with a thickness of 0.8-1.2um is grown on the first GaN...

Embodiment 2

[0067] See structure image 3 .

[0068] 1. Place the sapphire substrate 1 in the MOCVD reaction chamber, and use H 2 , NH 3 Treat the sapphire substrate 1 with the gas at high temperature for 4 to 10 minutes;

[0069] 2. After the treatment is completed, the temperature of the reaction chamber is lowered to 500-550°C, and TMGa and NH 3 , with a pressure of 300-900 mbar, growing a low-temperature first GaN buffer layer 2 (Nucleation) with a thickness of 20-50 nm on the sapphire substrate 1;

[0070] 3. After the first GaN buffer layer 2 is grown, the temperature is raised to 950-1050°C, and the temperature is annealed at a high temperature for 60-300s to form a GaN crystal nucleus on the substrate 1;

[0071] 4. After the high-temperature annealing is completed, the temperature is adjusted to 960-1020°C, and TMGa and NH 3 , the pressure is controlled at 300-900mbar, and a high-temperature non-doped first uGaN layer 3 with a thickness of 0.8-1.2um is grown on the first GaN...

Embodiment 3

[0087] See structure image 3 .

[0088] 1. Place the sapphire substrate 1 in the MOCVD reaction chamber, and use H 2 , NH 3 Treat the sapphire substrate 1 with the gas at high temperature for 4 to 10 minutes;

[0089] 2. After the treatment is completed, the temperature of the reaction chamber is lowered to 500-550°C, and TMGa and NH 3 , with a pressure of 300-900 mbar, growing a low-temperature first GaN buffer layer 2 (Nucleation) with a thickness of 20-50 nm on the sapphire substrate 1;

[0090] 3. After the first GaN buffer layer 2 is grown, the temperature is raised to 950-1050°C, and the temperature is annealed at a high temperature for 60-300s to form a GaN crystal nucleus on the substrate 1;

[0091] 4. After the high-temperature annealing is completed, the temperature is adjusted to 960-1020°C, and TMGa and NH 3 , the pressure is controlled at 300-900mbar, and a high-temperature non-doped second buffer GaN layer 3 with a thickness of 0.8-1.2um is grown on the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com