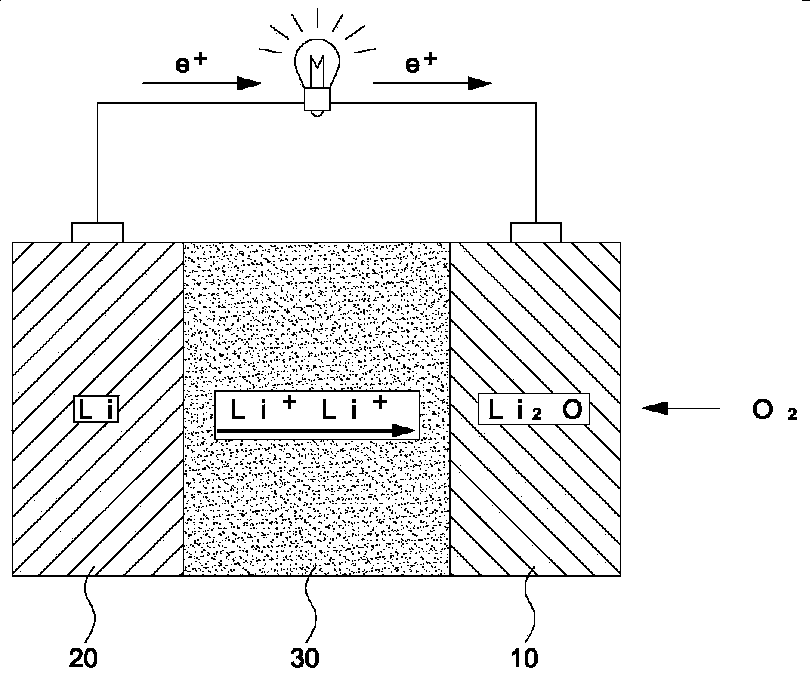

Lithium-air battery

A lithium-air battery, electronic technology, applied in battery electrodes, fuel cell components, circuits, etc., can solve safety problems, cathode degradation, reduce air battery charge and discharge characteristics and other problems, to improve battery performance, avoid electrolytes No deterioration in volatilization and charge-discharge characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] TGP-H-30 carbon paper from Torray Co. was used as the anode, and the electronically conductive substance in Table 1 below was used as the electronically conductive substance for coating. Mix 80 parts by weight of electronically conductive material with 20 parts by weight of binder PVDF to prepare slurry, with 1.0±0.1mg carbon / cm 2 The density is coated on the TGP-H-30 carbon paper of the TORRAY company. Thereafter, in order to remove the residual solvent, it was vacuum-dried at 100° C. for 12 hours.

[0047] [Table 1]

[0048]

electronically conductive substance

Example 1-1

Super P

Example 1-2

Vulcano Carbon

Example 1-3

CMK

Example 1-4

CNT

Example 1-5

Examples 1-6

Acetylene black

Examples 1-7

Ketjen Black

[0049] The gas diffusion layer (GDL) coated with electronically conductive material prepared above was used as the air electrode, lithium metal was use...

Embodiment 2

[0053] TGP-H-30 carbon paper from Torray Company was used as the anode, and super P was used as the electronically conductive material, and the coating was performed under the same conditions as in Example 1 above.

[0054] The above prepared gas diffusion layer (GDL) coated with electronically conductive material was used as the air electrode, metal lithium was used as the cathode, the electrolyte in the following list 2 was used as the electrolyte, and a porous polyethylene film was used as the separator (Celgard, LLC., Celgard3501), made of 2032 coin-type batteries.

[0055] [Table 2]

[0056]

[0057] At the temperature shown in the above table 2, the charge and discharge capacity of the lithium-air batteries prepared in the above examples 2-1 to 2-4 were measured, and the results are shown in Figure 9 to Figure 17 .

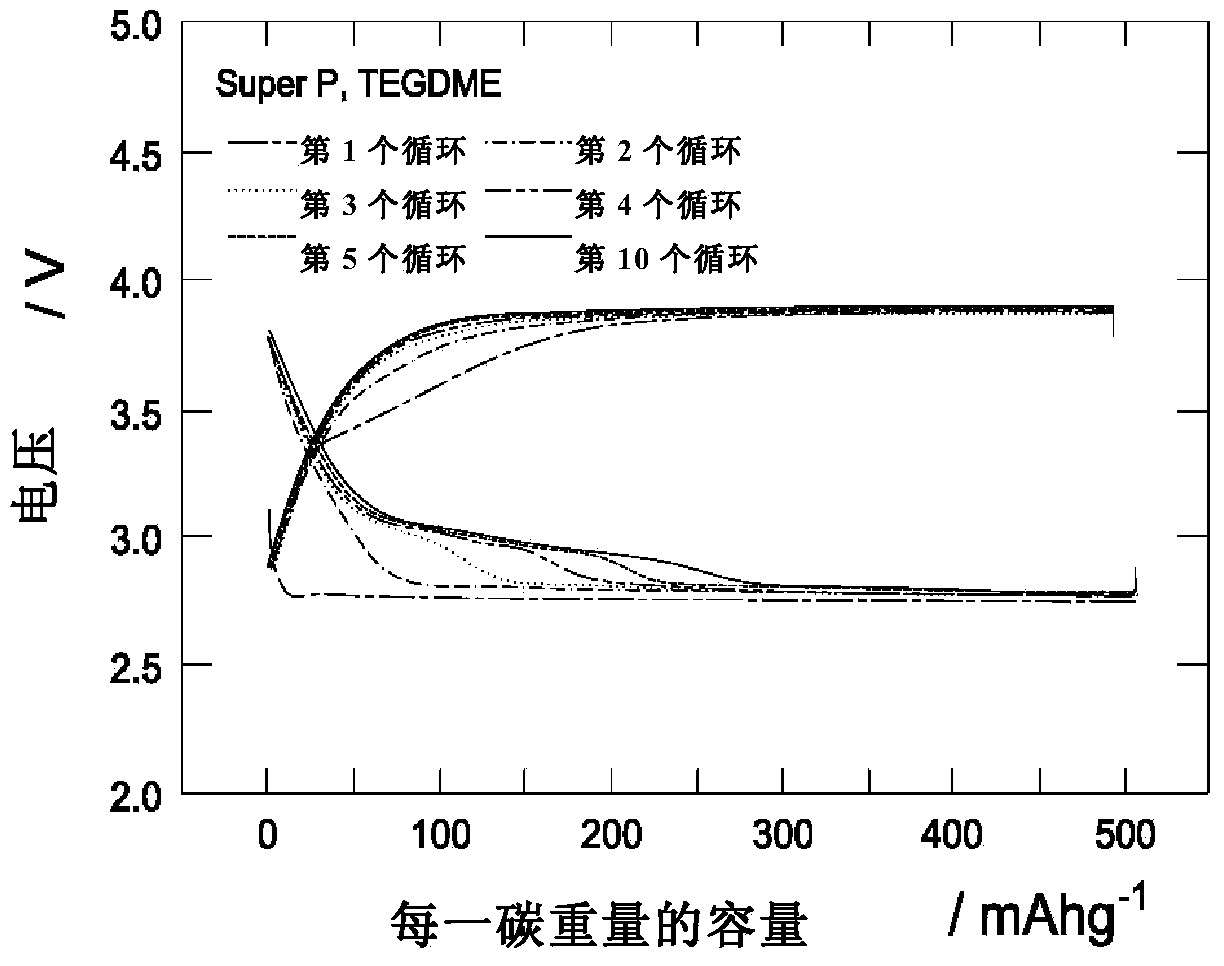

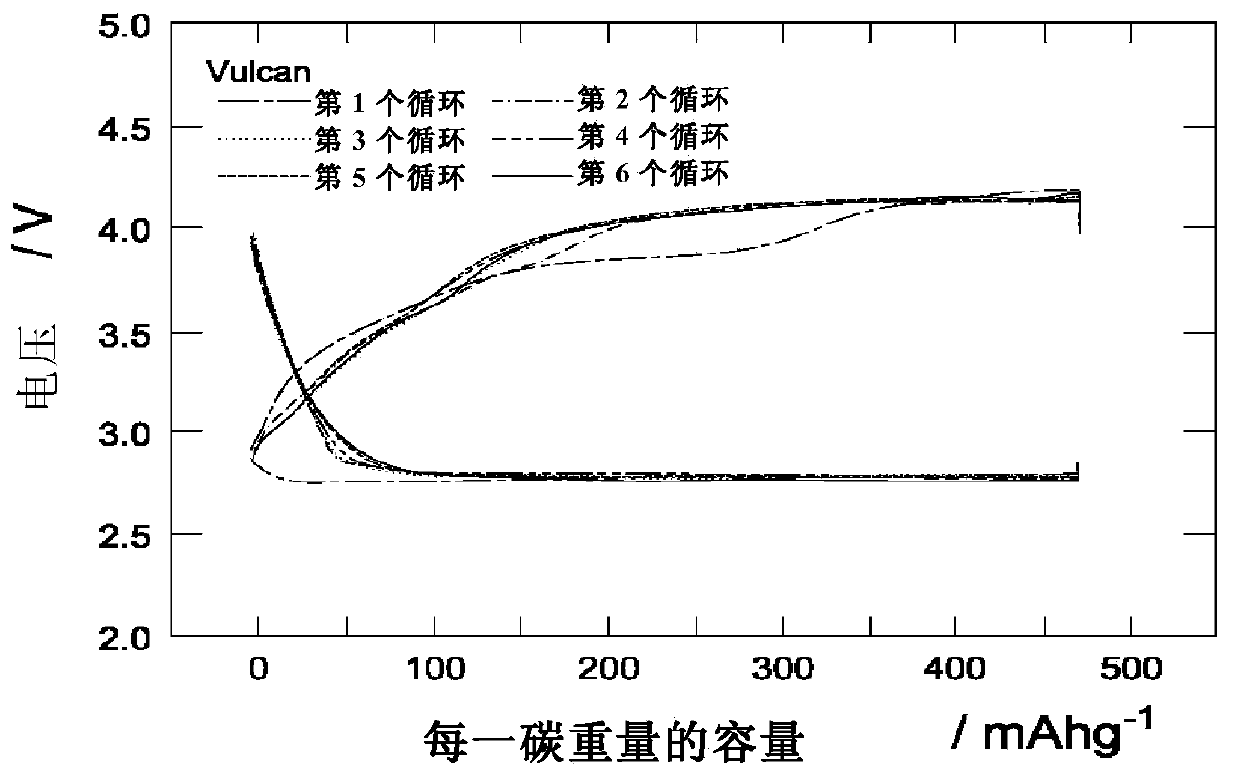

[0058] Depend on Figure 9 to Figure 17 It can be seen that when TEGDME is used as the electrolyte, the charge voltage is 4.0V, and the discharge vol...

Embodiment 3

[0060] Use the TGP-H-30 carbon paper of Torray Company as anode, use super P as electronic conductivity material, the super P of 80 weight parts is mixed with the adhesive agent of 20 weight parts shown in following table 3, implement with above-mentioned Example 1 Preparation of anode and air electrode.

[0061] [table 3]

[0062] differentiate

Electrolyte used

Example 3-1

PVdF

Example 3-2

PEOs

Example 3-3

Kynar

[0063] The charge-discharge capacity of the lithium-air battery prepared in the above-mentioned examples 3-1 to 3-3 is measured, and the results are shown in Figure 18 to Figure 20 .

[0064] Depend on Figure 18 to Figure 20 It can be seen that the charge voltage is similar to the discharge voltage, although it differs depending on the type of binder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com