Salt bath brazing craft process of 6063 aluminum alloy

A technology of salt bath brazing and technological process, which is applied in metal processing equipment, manufacturing tools, welding equipment, etc., and can solve problems such as poor brazing performance and low melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

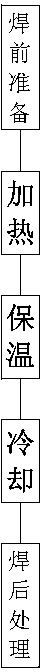

[0011] Below in conjunction with accompanying drawing and example the present invention will be further described:

[0012] Such as figure 1 Shown, a kind of salt-bath brazing process of 6063 aluminum alloy, described brazing process steps are successively:

[0013] a) Preparation before welding: soak the base metal 6063 aluminum alloy and solder in 5% (mass fraction) sodium hydroxide solution at 60°C for 1-2 minutes to remove surface impurities and oil stains, then rinse with plenty of water, After drying, the workpiece is clamped with a fixture;

[0014] b) Heating: Put the salt bath tank with flux into the furnace protected by nitrogen to heat up to 560°C;

[0015] c) Heat preservation: put the pre-equipped parts into the salt bath for a certain period of time;

[0016] d) Cooling: take out the workpiece to cool;

[0017] e) Post-welding treatment: Rinse the workpiece in boiling water to remove residual flux on the surface of the workpiece, then put it in a pickling tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com