Mobile oil tank (pipe) ultrahigh pressure water jet cutting device

A cutting device and mobile technology, applied in the direction of used abrasive processing devices, abrasive jet machine tools, abrasives, etc., can solve problems such as not suitable for cutting requirements, and achieve the elimination of environmental pollution and hazards to workers' health, efficiency Good uniformity and small counter-spraying force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

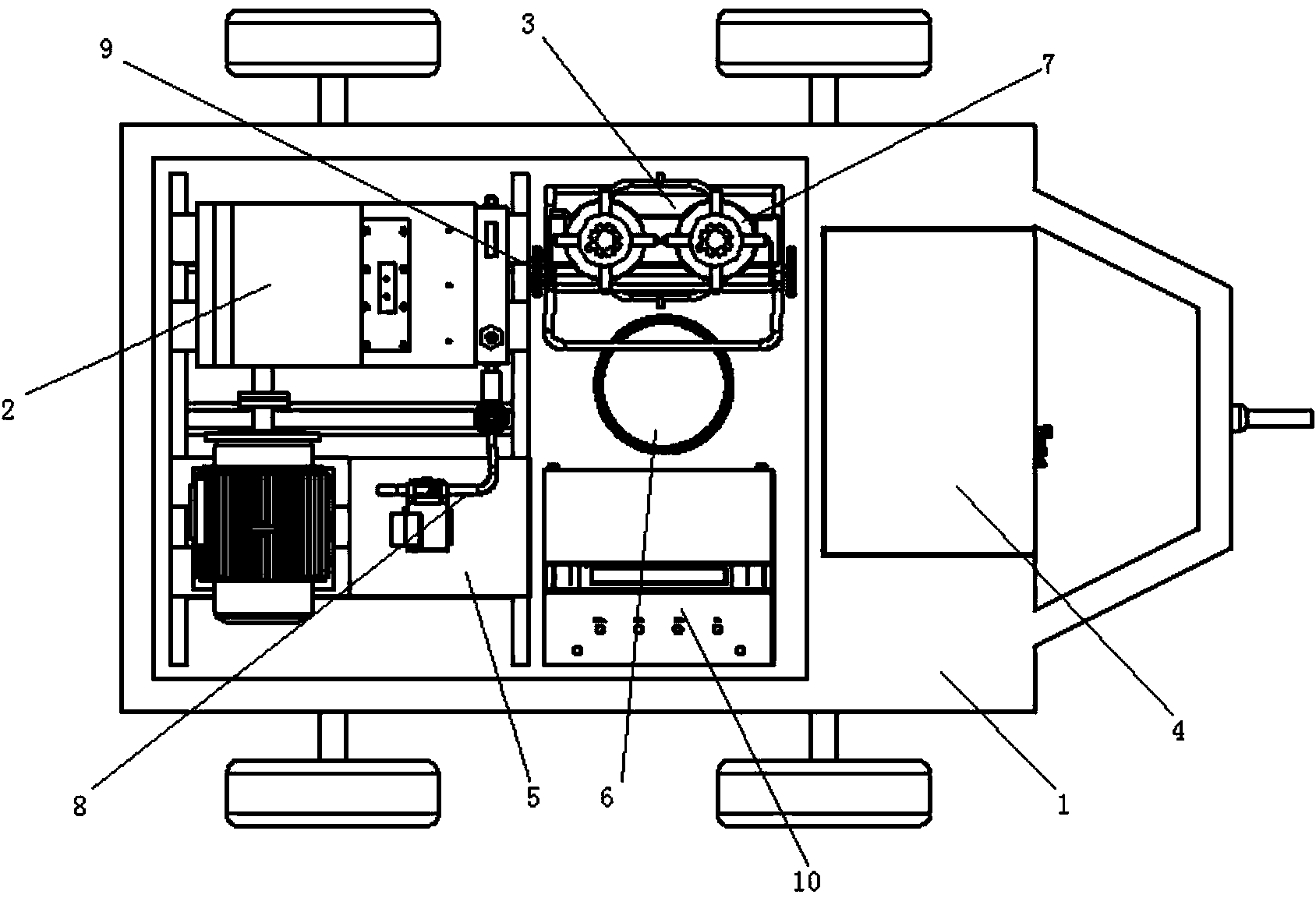

[0019] Referring to the accompanying drawings, the mobile oil tank (pipe) ultra-high pressure water jet cutting device includes a mobile trailer 1, on which a plunger pump 2, an abrasive jet generator 3, an actuator 4, a water tank 5, and a water pump 6 are installed. , the plunger pump 2 is driven and connected by a motor, the actuator 4 includes a drive motor, a reducer, and a cutting head, and the abrasive jet generating device 3 includes two abrasive tanks 7, an abrasive mixing device, an abrasive shut-off valve, and a screw cap, There is a cock-type exhaust and pressure relief valve on the screw cap, and the water pump pumps the water in the water tank into the abrasive jet generator, and the abrasive slurry from the abrasive jet generator is delivered to the nozzle of the actuator through the high-pressure rubber hose 8 to form an abrasive jet. , a pressure gauge 9 is installed on the abrasive pot, and a control system 10 is also installed on the mobile trailer 1 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com