Apparatus and method for producing high-purity yellow phosphorus

A production device and pure yellow phosphorus technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems that it is difficult to achieve ideal and economical results, the impurity components of industrial yellow phosphorus are complicated, and the purification effect is limited. , to achieve continuous production operation, not easy to leak, and improve the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

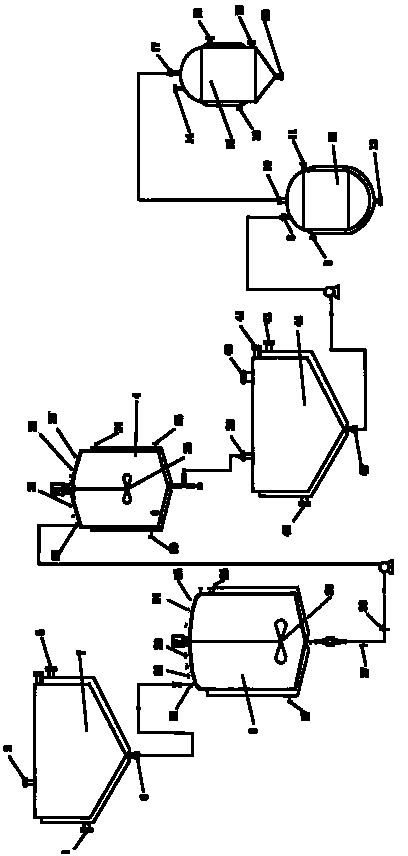

[0026] A high-purity yellow phosphorus production device, including an oxidation device, a washing device, a crystallization device and a filtration device;

[0027] The oxidation device includes a phosphorus melting tank 7 and an oxidation tank 3; the top of the phosphorus melting tank 7 is provided with a yellow phosphorus inlet 2, the bottom of the phosphorus melting tank 7 is provided with a yellow phosphorus outlet 6, and the outer layer of the phosphorus melting tank 7 is provided with Insulation jacket, the lower part of the insulation jacket is provided with an insulation fluid inlet 1, and an insulation fluid outlet 5 is provided on the opposite side of the insulation jacket insulation fluid inlet; the top of the oxidation tank 3 is respectively provided with an oxidation tank yellow phosphorus inlet 21 , oxidant inlet 22, catalyst inlet 23, nitrogen inlet 24 and exhaust gas outlet 25; The bottom of described oxidation tank 3 is provided with oxidation tank yellow phos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com