Special nutrient synchronous controlled-release fertilizer for thermal plant sweet waxy maizes

A technology of sweet waxy corn and controlled-release fertilizer, applied in application, fertilization device, fertilizer mixture, etc., can solve the problems of unacceptable, unfavorable application and high cost of corn for farmers, avoid defertilization and leggy growth, and achieve stable and regular nutrient supply , The effect of increasing production and efficiency is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

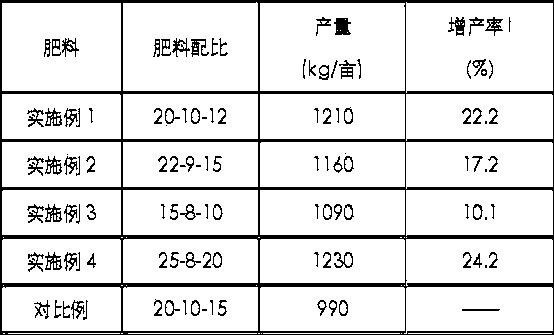

Embodiment 1

[0032] Example 1: Nutrient synchronous controlled-release fertilizer dedicated to hot-growing sweet waxy corn. The ratio of total nutrients: nitrogen, phosphorus pentoxide, and potassium oxide is 20:10:12, both in mass percentage. The raw material components are as follows: The raw material components characterized in their parts by weight are: ordinary urea (46% N content) 160kg, controlled release urea (30-60 days, N content 43%, produced and sold by China BlueChemical) 80kg, controlled release Urea (60-90 days, N content 43%, produced and sold by China BlueChemicals) 160kg, monoammonium phosphate (N content 11%, P 2 o 5 Content 44%) 230 kg and potassium chloride (K 2 O content 60%) 200 kg, zinc sulfate 3kg. Mix the materials mechanically and pack them into bags.

Embodiment 2

[0033] Example 2: Nutrient synchronous controlled-release fertilizer dedicated to hot-growing sweet waxy corn. The proportions of total nutrients: nitrogen, phosphorus pentoxide, and potassium oxide are 22:9:15, all in mass percent. The raw material components are as follows:

[0034] Ordinary urea (N content 46%) 150 kg, controlled-release urea (30-60 days, N content 43%, produced and sold by China BlueChemicals) 100kg, controlled-release urea (60-90 days, N content 43%, produced and sold by China BlueChemicals) ) 200kg, monoammonium phosphate (N content 11%, P 2 o 5 Content 44%) 270kg and potassium sulfate (K 2 O content 50%) 300kg, zinc sulfate 4kg. Mix the materials mechanically and pack them into bags.

Embodiment 3

[0035] Example 3: Nutrient synchronous controlled-release fertilizer dedicated to hot-growing sweet waxy corn. The ratios of total nutrients: nitrogen, phosphorus pentoxide, and potassium oxide are 15:8:10, all in mass percent. The raw material components are as follows:

[0036] Ordinary urea (N content 46%) 128 kg, controlled-release urea (30-60 days, N content 43%, produced and sold by China BlueChemicals) 64kg, controlled-release urea (60-90 days, N content 43%, produced and sold by China BlueChemicals) ) 128kg, diammonium phosphate (N content 18%, P 2 o 5 Content 46%) 175kg and potassium chloride (K 2 O content 60%) 170kg, zinc sulfate 2 kg. Mix the materials mechanically and pack them into bags.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com