Mud cake hardening enhancer for drilling fluid

A technology of reinforcing agent and hardening agent, which is applied in the field of drilling fluid additives to achieve the effects of improving hardening, good cementing effect, and improving cementing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 32g of bishydroxyethoxypropyl polydimethylsiloxane, 48g of whisker silicon, the fiber length of whisker silicon is 300 μm, the diameter is 5 μm, 3-aminopropylmethyldiethoxysilane 6g, layered crystalline sodium disilicate 10g, acrylic acid-hydroxypropyl acrylate copolymer T-225 4g, mixed with each other evenly to prepare mud cake hardening enhancer product for drilling fluid.

Embodiment 2

[0033] Weigh 35g of bishydroxyethoxypropyl polydimethylsiloxane, 42g of whisker silicon, the fiber length of whisker silicon is 150 μm, the diameter is 10 μm, 3-aminopropylmethyldiethoxysilane 8g, 12g of layered crystalline sodium disilicate, and 3g of acrylic acid-hydroxypropyl acrylate copolymer T-225, mixed with each other evenly to prepare mud cake hardening enhancer for drilling fluid.

Embodiment 3

[0035] Weigh 38g of bishydroxyethoxypropyl polydimethylsiloxane, 36g of whisker silicon, the fiber length of whisker silicon is 500 μm, the diameter is 10 μm, 3-aminopropylmethyldiethoxysilane 10g, layered crystalline sodium disilicate 14g, acrylic acid-hydroxypropyl acrylate copolymer T-225 2g, mixed with each other evenly to prepare mud cake hardening enhancer for drilling fluid.

[0036] The performance evaluation of the mud cake hardening enhancer for drilling fluid in the above-mentioned embodiment was performed by the following method.

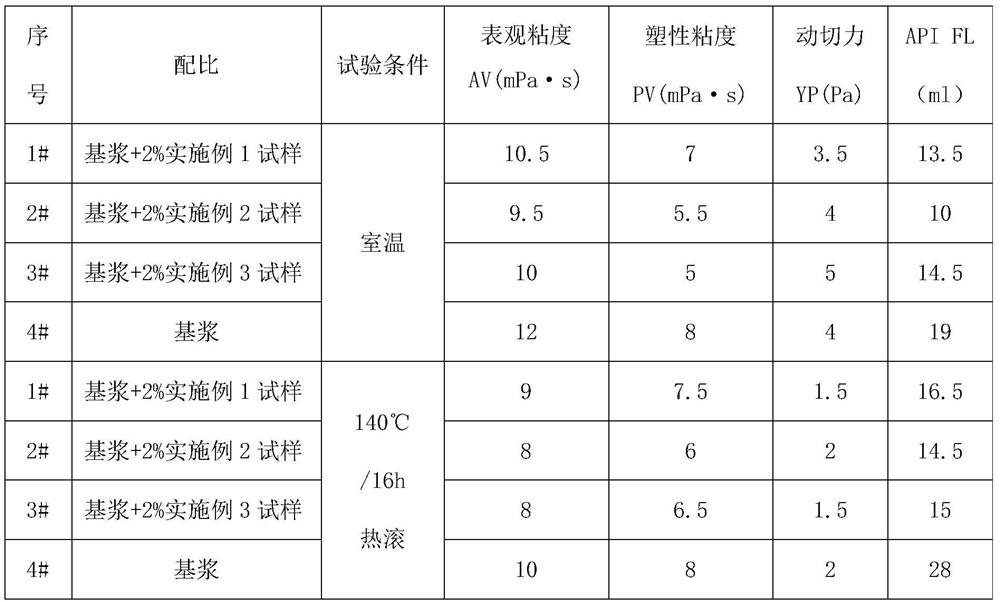

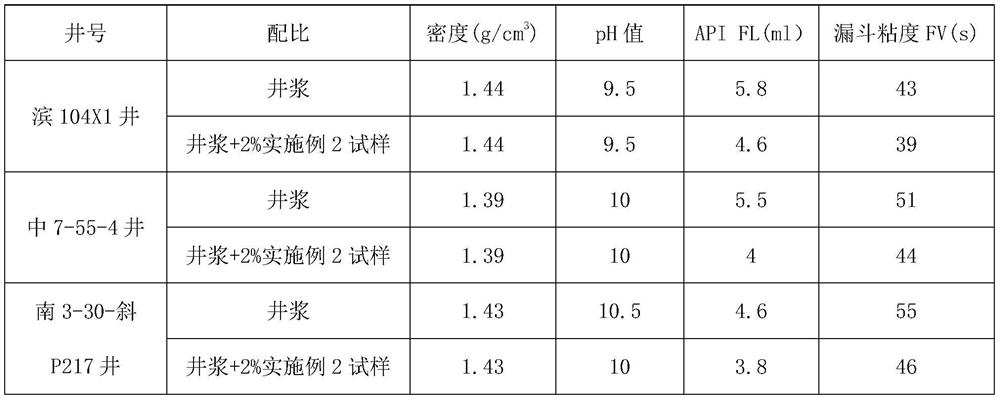

[0037] (1) Compatibility with drilling fluid and high temperature resistance evaluation methods are as follows:

[0038]The drilling fluid used is 4% base slurry. The 4% base slurry is to add 4g of sodium bentonite per 100mL of water, stir well, seal and let stand, and maintain at room temperature for 24 hours to hydrate to obtain base slurry.

[0039] (1.1) Performance evaluation at room temperature: Prepare 4 slurry cups, labeled 1#, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com