Preparation method of milk thistle extract with high content and low soluble residue

A milk thistle, high-content technology, applied in organic chemistry and other fields, can solve the problems of difficult separation and purification, high price, large consumption of auxiliary raw materials, etc., and achieve the effect of simple process and low solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

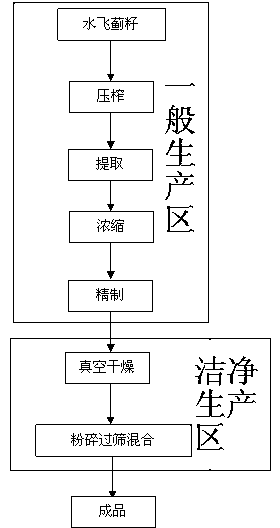

[0018] Such as figure 1 As shown, the preparation method of milk thistle extract with high content and low solvent residue disclosed in the present invention includes the following steps, (1), pressing: pressing the cleaned and dried milk thistle seeds through a screw oil press, Obtaining milk thistle residue cake; (2), extraction: pulverizing the milk thistle residue cake obtained in step (1), mixing it with an extraction solvent to obtain a mixture, extracting through a reverse gradient circulation extraction device, and filtering to obtain an extract; (3) Concentration: pump the extract obtained in step (2) into an external circulation concentrator for concentration to obtain a concentrate; (4) Refining: pump the concentrate obtained in step (3) into a ribbon mixer Extraction was carried out in the concentrated solution, and n-hexane was added to the concentrated solution, heated and stirred for 1 hour, the organic layer was pumped off, and the extraction operation was ...

Embodiment 1

[0025] (1) Pressing: Take 6 tons of milk thistle seeds, put them in at 150-200 kg per hour and press them through a screw press.

[0026] (2) Extraction: crush the pressed milk thistle residue cake, extract with butanone 95±5% (V / V) and reverse gradient circulation extraction equipment, and filter to obtain the extract.

[0027] (3) Concentration: pump the extract into the external circulation concentrator for concentration, the concentration vacuum is -0.06Mpa, and the concentration temperature is 55°C.

[0028] (4) Refining: pump the concentrated solution into a ribbon mixer for extraction, add 4 times the amount (V / V) of n-hexane to the concentrated solution, heat at 45°C, stir and extract for 1 hour, and the organic layer passes through the pump Extract and repeat the extraction operation twice; the water layer is concentrated under reduced pressure until solvent-free distillation is obtained to obtain the liquid extract I; the liquid extract I is dissolved with 20 times t...

Embodiment 2

[0033] (1) Pressing: Take 6 tons of milk thistle seeds, put them in at 150-200 kg per hour and press them through a screw press.

[0034] (2) Extraction: crush the pressed milk thistle residue cake, extract with acetone 95±5% (V / V) and reverse gradient circulation extraction equipment, and filter to obtain the extract.

[0035] (3) Concentration: pump the extract into the external circulation concentrator for concentration, the concentration vacuum is -0.05Mpa, and the concentration temperature is 60°C.

[0036](4) Refining: pump the concentrated solution into a ribbon mixer for extraction, add 4 times the amount (V / V) of n-hexane to the concentrated solution, heat at 48°C, stir and extract for 1 hour, and the organic layer passes through the pump Extract and repeat the extraction operation twice; the water layer is concentrated under reduced pressure until solvent-free distillation is obtained to obtain the liquid extract I; the liquid extract I is dissolved with 20 times the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com