Photothermal Synergistic Controllable Degradation Polymer Composite Masterbatch and Its Preparation Method

A photothermal synergy, polymer material technology, applied in the field of polymer materials, can solve problems such as the limitations of photocatalytic degradation technology, and achieve the effects of expanding the application range, regulating the degradation induction period, and reducing the dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

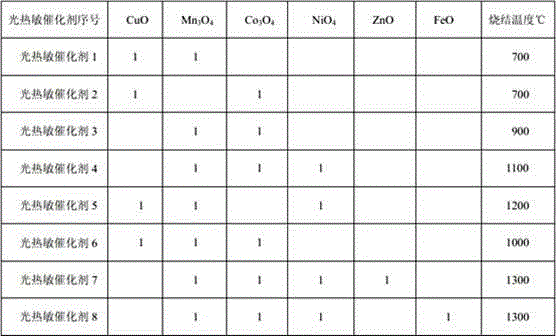

Image

Examples

Embodiment 1

[0017] Example 1 : Take 14 parts of photothermal catalyst according to the weight ratio, add 00.2 parts of titanate coupling agent, mix at high speed for 5 minutes in a high-speed mixer, then add 80 parts of polyethylene and 10100.1 parts of antioxidant and mix at high speed Mix in machine on high speed for 15 minutes. The premixed material was placed in a twin-screw extruder, and modified by melt blending at 140° C. for 5 minutes. Extrude at a die temperature of 130°C and a screw speed of 20 rpm, cool under natural air, and pelletize through a pelletizer to obtain a photothermal synergistic controllable degradable polymer composite masterbatch.

Embodiment 2

[0018] Example 2 : Get 23 parts of photothermal catalysts by weight, add 0.15 parts of aluminate coupling agent, mix at high speed in high-speed mixer for 5 minutes, then add 85 parts of polystyrene and 10100.1 parts of antioxidant, anti-oxidant 0.1 part of oxygen agent MB was mixed in a high-speed mixer for 15 minutes at high speed. The premixed material was placed in a twin-screw extruder, and modified by melt blending at 160° C. for 4 minutes. Extrude at a die temperature of 150°C and a screw speed of 50 rpm, cool under natural air, and pelletize through a pelletizer to obtain a photothermal synergistic controllable degradable polymer composite masterbatch.

Embodiment 3

[0019] Example 3 : Take 34 parts of photothermal catalysts in proportion by weight, add 0.1 part of aluminate coupling agent, 0.1 part of silane coupling agent, mix at high speed in high-speed mixer for 5 minutes, then add 80 parts of polypropylene and anti- 0.1 part of oxygen agent CA was mixed in a high-speed mixer for 15 minutes at high speed. The premixed material was placed in a twin-screw extruder, and modified by melt blending at 180° C. for 3 minutes. Extrude at a die temperature of 160°C and a screw speed of 80 rpm, cool under natural air, and pelletize through a pelletizer to obtain a photothermal synergistic controllable degradable polymer composite masterbatch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com