A kind of galvanized steel strand used for overhead guy wire and its production process

A galvanized steel strand and production process technology, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve the problems of easy fracture, corrosion, not very smooth, short service life, etc., to achieve safety Sexual guarantee, good thermal insulation effect, and the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

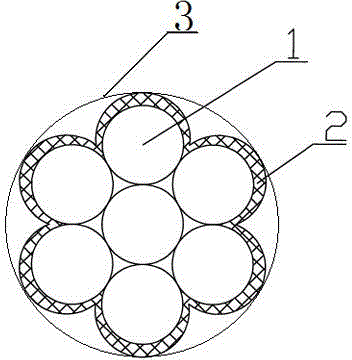

[0046]The present embodiment provides a galvanized steel strand for overhead guy wires, the structure of which is as follows: figure 1 As shown, it is composed of seven steel wires 1 with a diameter of 6.6 mm, one of which is located at the center of the other six steel wires 1 evenly distributed on the same circumference, and the seven steel wires 1 are tightly fitted and each steel wire 1 is equipped with a plating on the outside. Zinc layer 2, the outside of the galvanized layer 2 is covered with a layer of rubber sleeve 3;

[0047] The weight percentage composition of steel wire 1 is: C: 0.15%, Mn: 1.17%, Si: 0.9%, P: 0.03%, S: 0.01%, Mo: 0.14%, Ni: 0.3%, Cu: 0.13%, Ti : 0.16%, Al: 0.06%, lanthanide rare earth: 0.15%, the balance is Fe;

[0048] The mass percentages of the lanthanide rare earth components are: La: 23%, Y: 15%, Sc: 17%, Gd: 20%, Sm: 16%; other lanthanide elements: 9%.

[0049] The production process of galvanized steel strands for overhead guy wires is ca...

Embodiment 2

[0070] The present embodiment provides a galvanized steel strand for overhead guy wires, the structure of which is as follows: figure 1 As shown, it is composed of seven steel wires 1 with a diameter of 6.6 mm, one of which is located at the center of the other six steel wires 1 evenly distributed on the same circumference, and the seven steel wires 1 are tightly fitted and each steel wire 1 is equipped with a plating on the outside. Zinc layer 2, the outside of the galvanized layer 2 is covered with a layer of rubber sleeve 3;

[0071] The weight percentage composition of steel wire 1 is: C: 0.17%, Mn: 1.15%, Si: 0.8%, P: 0.04%, S: 0.008%, Mo: 0.13%, Ni: 0.2%, Cu: 0.12%, Ti : 0.15%, Al: 0.05%, lanthanide rare earth: 0.20%, the balance is Fe;

[0072] The mass percentages of the lanthanide rare earth components are: La: 22%, Y: 17%, Sc: 15%, Gd: 23%, Sm: 15%; other lanthanide elements: 8%.

[0073] The production process of galvanized steel strands for overhead guy wires is ...

Embodiment 3

[0094] The present embodiment provides a galvanized steel strand for overhead guy wires, the structure of which is as follows: figure 1 As shown, it is composed of seven steel wires 1 with a diameter of 6.6 mm, one of which is located at the center of the other six steel wires 1 evenly distributed on the same circumference, and the seven steel wires 1 are tightly fitted and each steel wire 1 is equipped with a plating on the outside. Zinc layer 2, the outside of the galvanized layer 2 is covered with a layer of rubber sleeve 3;

[0095] The weight percentage composition of steel wire 1 is: C: 0.17%, Mn: 1.15%, Si: 0.8%, P: 0.04%, S: 0.008%, Mo: 0.13%, Ni: 0.2%, Cu: 0.12%, Ti : 0.15%, Al: 0.05%, lanthanide rare earth: 0.18%, the balance is Fe;

[0096] The mass percentages of the lanthanide rare earth components are: La: 19%, Y: 14%, Sc: 18%, Gd: 22%, Sm: 20%; the remaining lanthanide elements: 7%.

[0097] The production process of galvanized steel strands for overhead guy w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com