PM2.5 protection composite screen window mesh

A technology of window screens and screens, which is applied in the field of composite screens, can solve the problems of poor filtration efficiency of fine particles, achieve the effects of ensuring air circulation and lighting, ensuring air permeability and light transmission, and improving air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

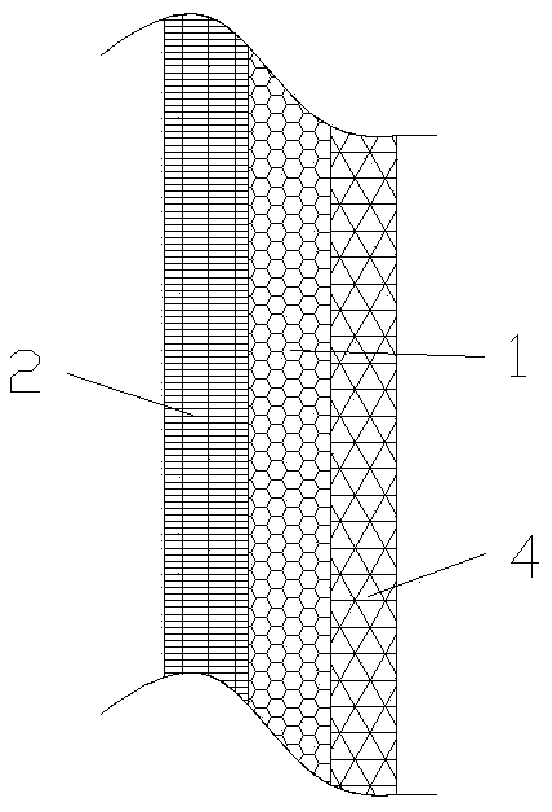

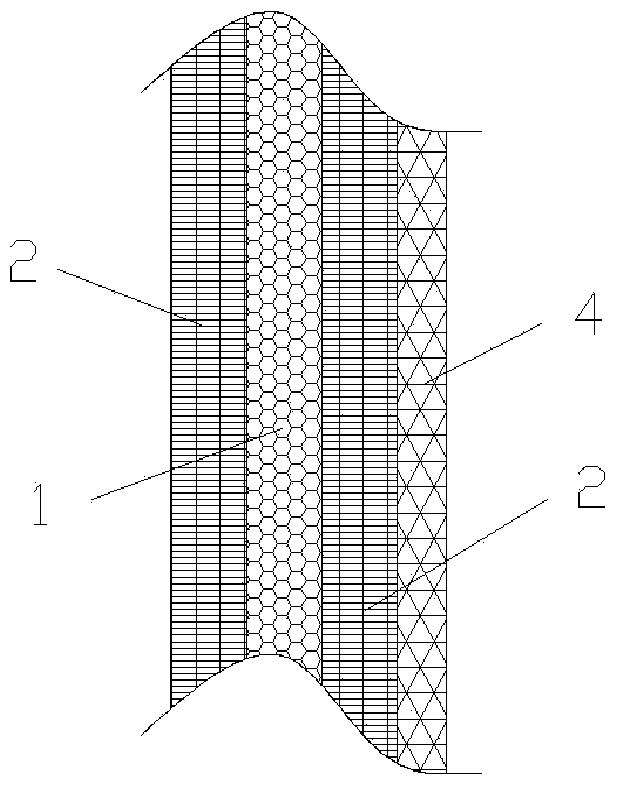

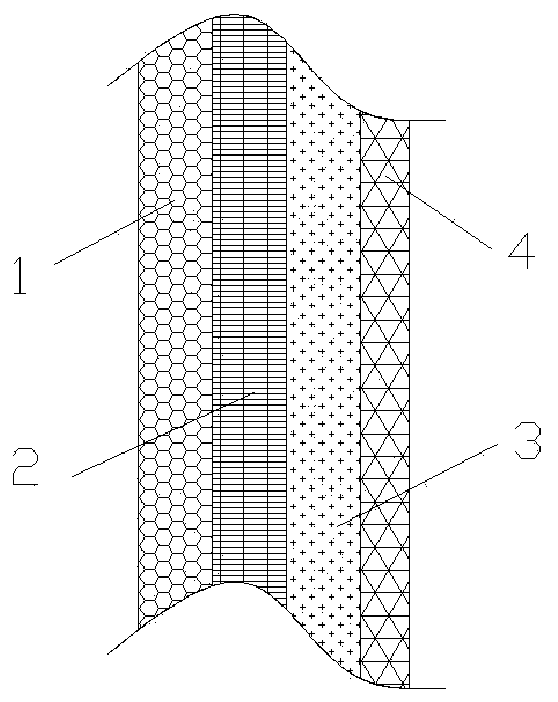

[0040] A kind of PM2.5 protection composite screen window net, structure such as figure 1 As shown, the composite screen netting includes a gauze layer 4, and an adsorption layer is provided on one side of the gauze layer 4, and the adsorption layer includes a layer of polypropylene spunbonded non-woven fabric layer 1 and a layer of ultrafine denier. Polar meltblown fiber nonwoven fabric layer 2, one side of polypropylene spunbonded nonwoven fabric layer 1 is closely attached to gauze layer 4, and the other side is closely attached to ultrafine denier electret meltblown fiber nonwoven fabric layer 2 A viscose strip is arranged on the outer periphery of the ultrafine denier electret melt-blown fiber nonwoven fabric layer 2 . The polypropylene spunbond nonwoven layer is evenly distributed with ventilating holes, the ventilating holes run through the polypropylene spunbond nonwoven layer, the aperture of the ventilating holes is 0.5 mm, and the polypropylene spunbond nonwoven lay...

Embodiment 2

[0044] a PM 2.5 Protective composite window screen, structure is as shown in embodiment 1, and difference is,

[0045] Ultrafine denier electret melt-blown fiber nonwoven layer 2 has a unit area weight of 30g / m 2 .

Embodiment 3

[0047] a PM 2.5 Protective composite window screen, the structure is as follows figure 1 As shown, the difference is that

[0048] Ultrafine denier electret melt-blown fiber nonwoven layer 2 has a unit area weight of 35g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com