A Crawler Hydraulic Cutting Drilling Rig with Intelligent Braking Device

A brake device and crawler-type technology, which is applied to drilling equipment, earthwork drilling, drilling equipment and methods, etc., can solve the problems of unstable gas supply pressure and gas volume, low drilling efficiency, and short service life, etc., to achieve Stable air pressure and volume, low maintenance and replacement costs, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

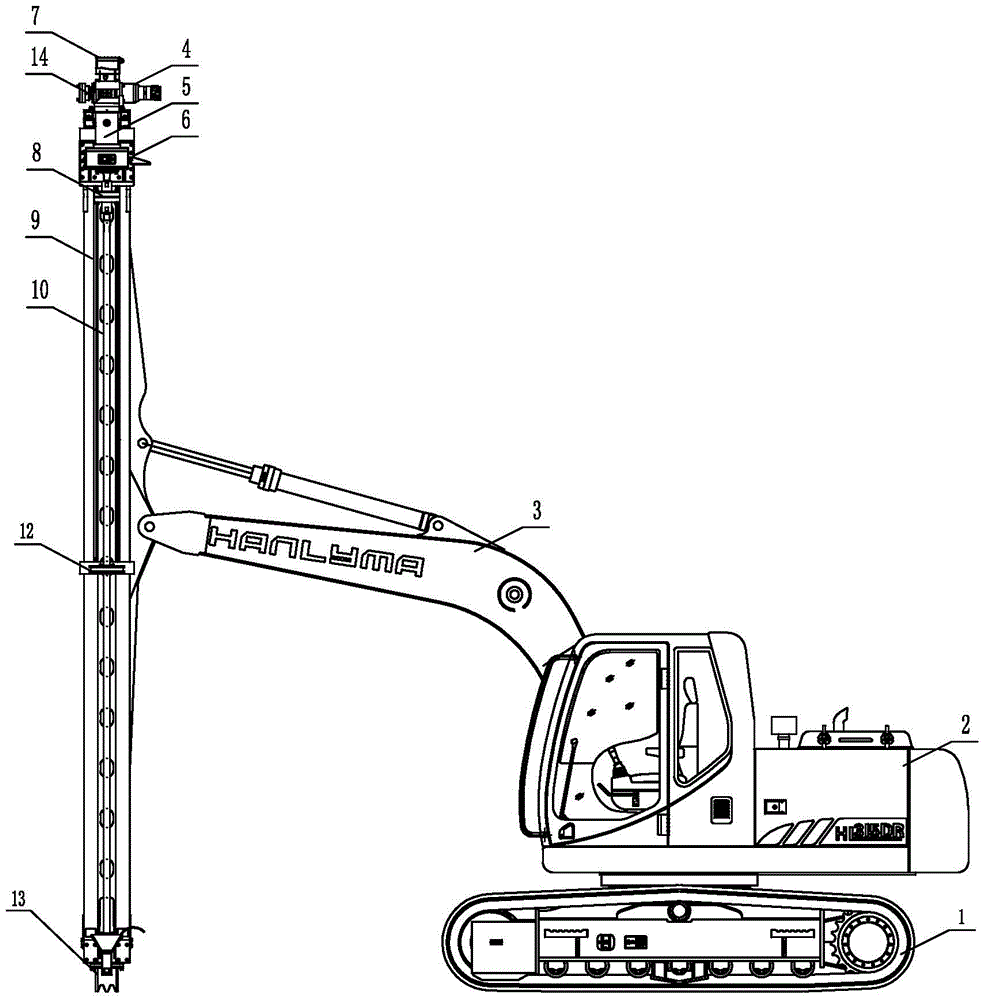

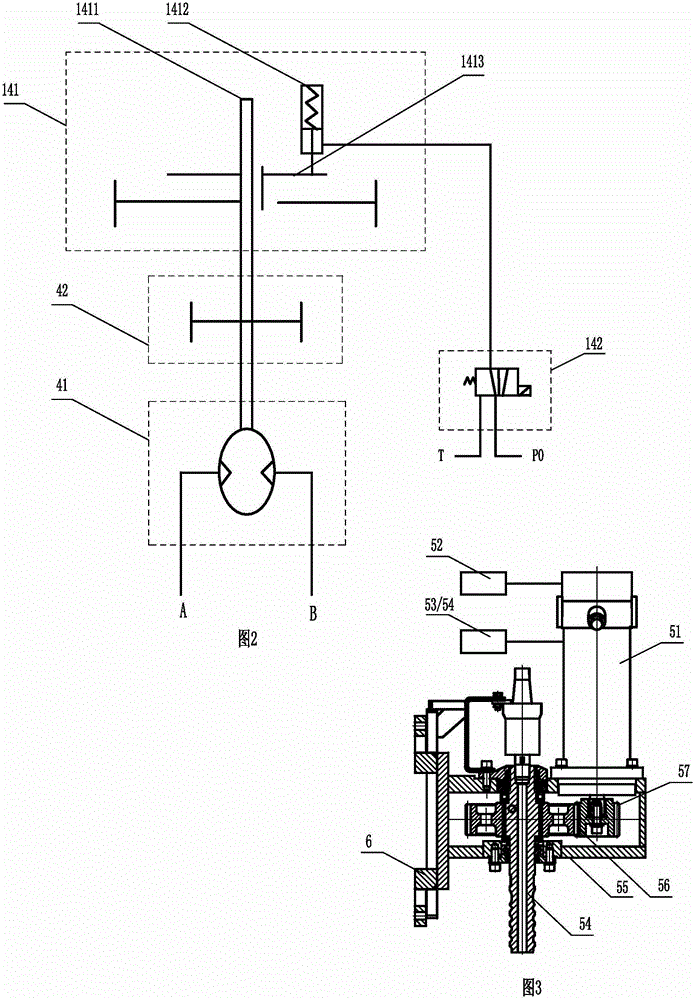

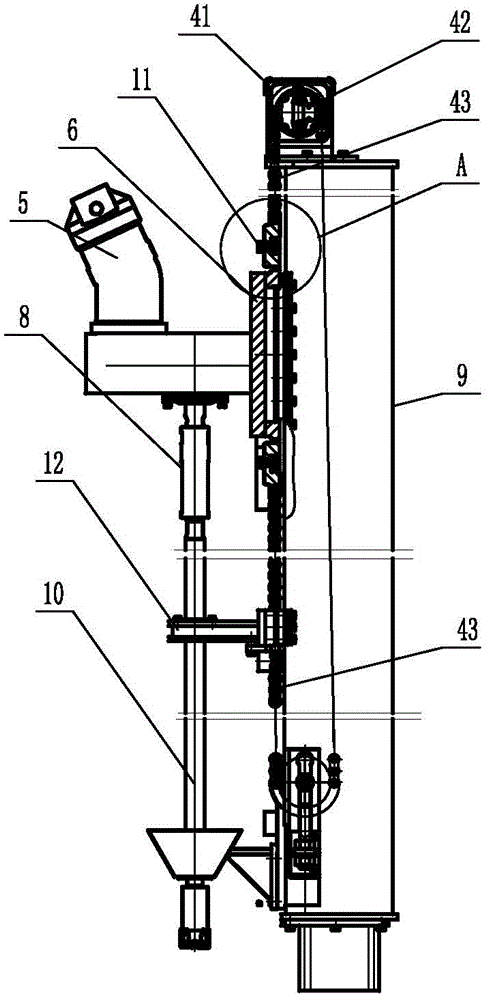

[0044] A crawler-type hydraulic cutting drilling rig with an intelligent braking device, comprising a boom 3, a drill boom 9 connected to the boom, a power head 5, a propulsion mechanism 4, an air compressor system 2 and a pressure oil source, the propulsion mechanism Installed on the drill arm, the power head is installed on the guide rail of the drill arm, and the cutting motor 51 installed in the power head is connected with the power head shaft 54 and the drill pipe 10 through the gearbox assembly. The mechanism drives the feeding and lifting of the drill pipe; the input oil circuit of the cutting motor communicates with the main hydraulic oil source P0 of the pressure oil source through the main control valve 53, and the main components of the air compressor system are installed on the drilling rig The fuselage, and communicate with the air blowing pipeline of the drilling arm through the pipeline installed on the drilling rig arm;

[0045] The top of the drill boom 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com