Tracking and controlling system and tracking method for heliostat

A tracking control and control system technology, used in solar heating systems, solar collector controllers, solar thermal devices, etc., can solve the problems of large amount of correction work, poor effect, high cost, etc., to overcome the amount of correction work. Bulky, overcoming ineffectiveness, reducing system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

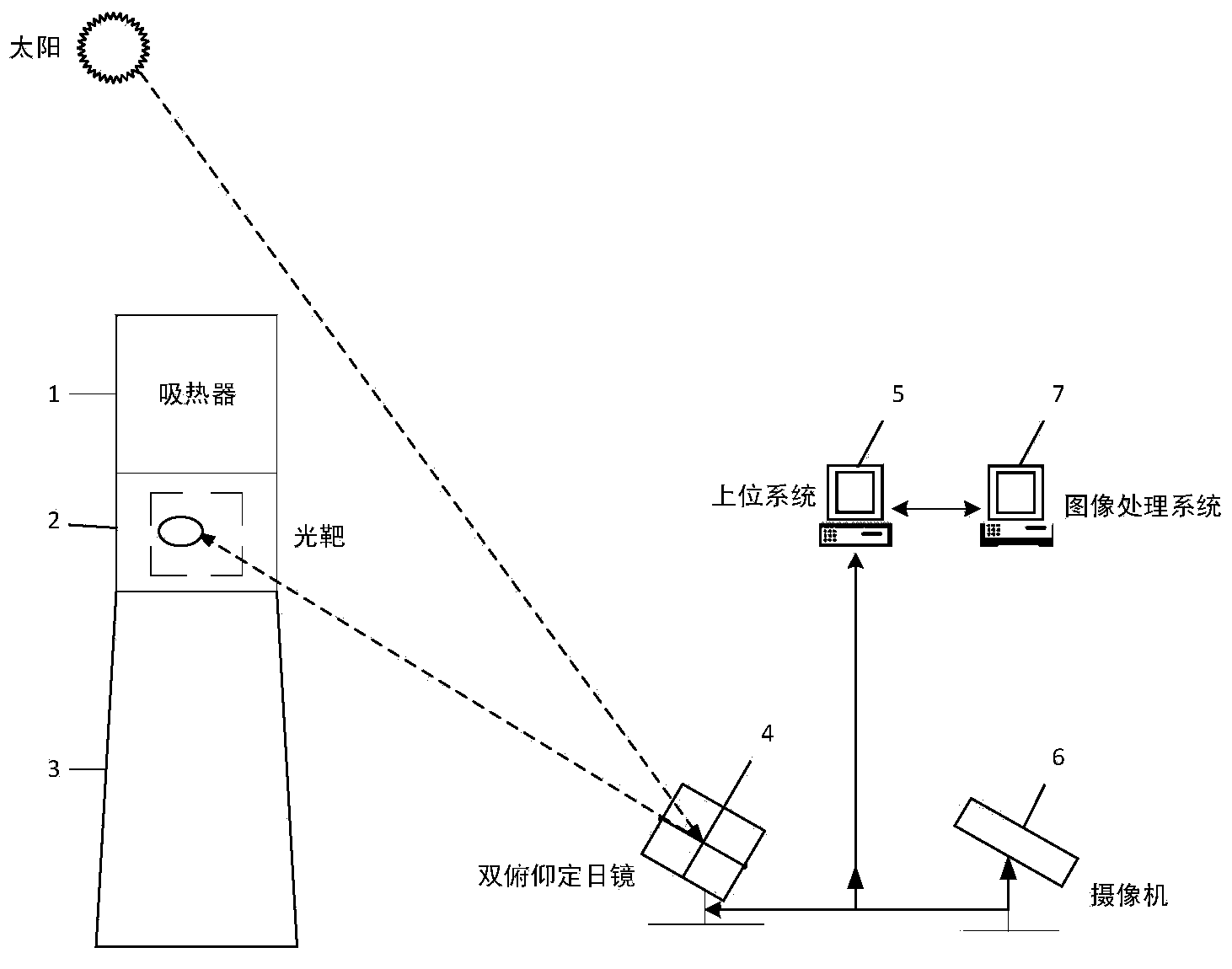

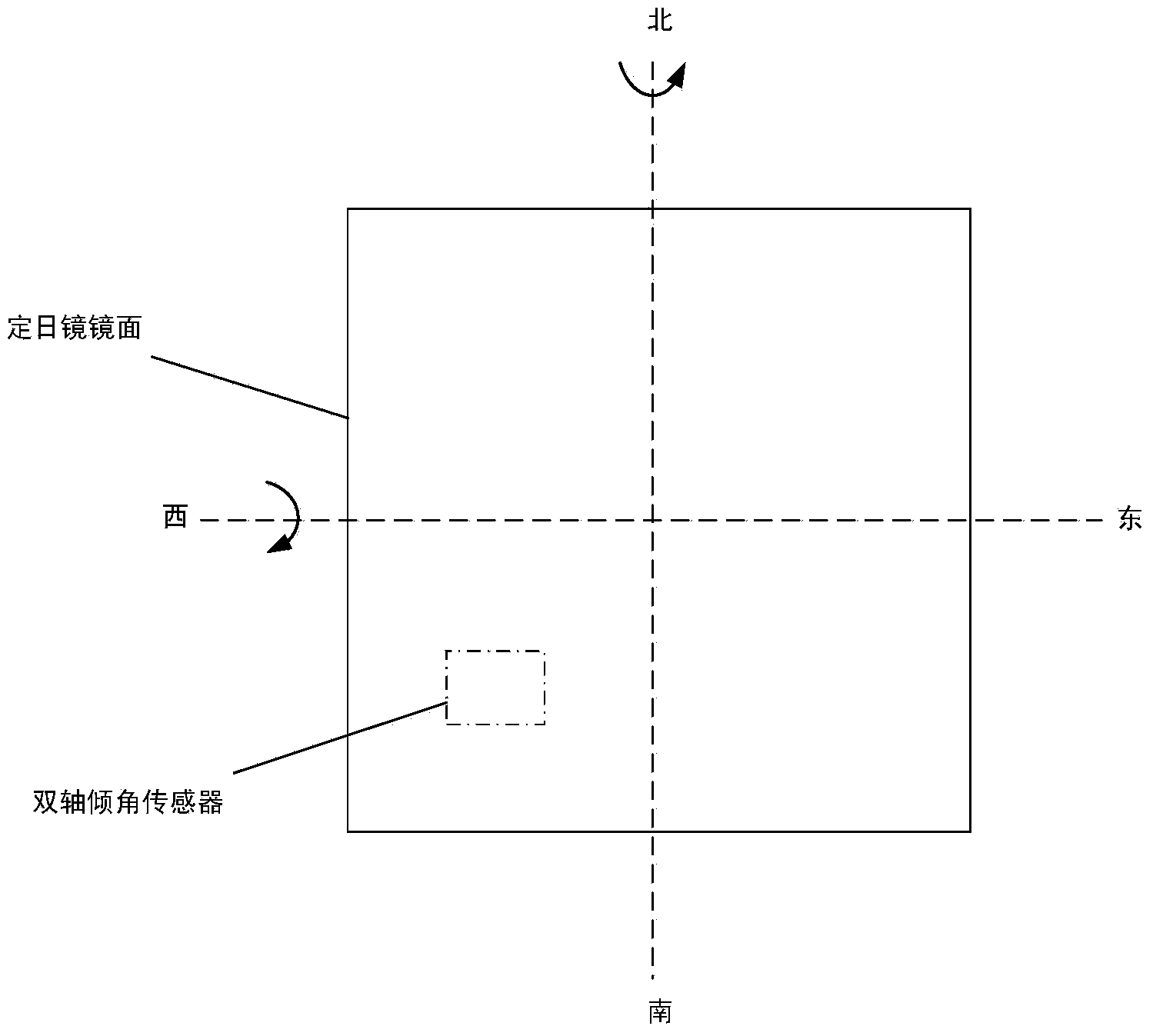

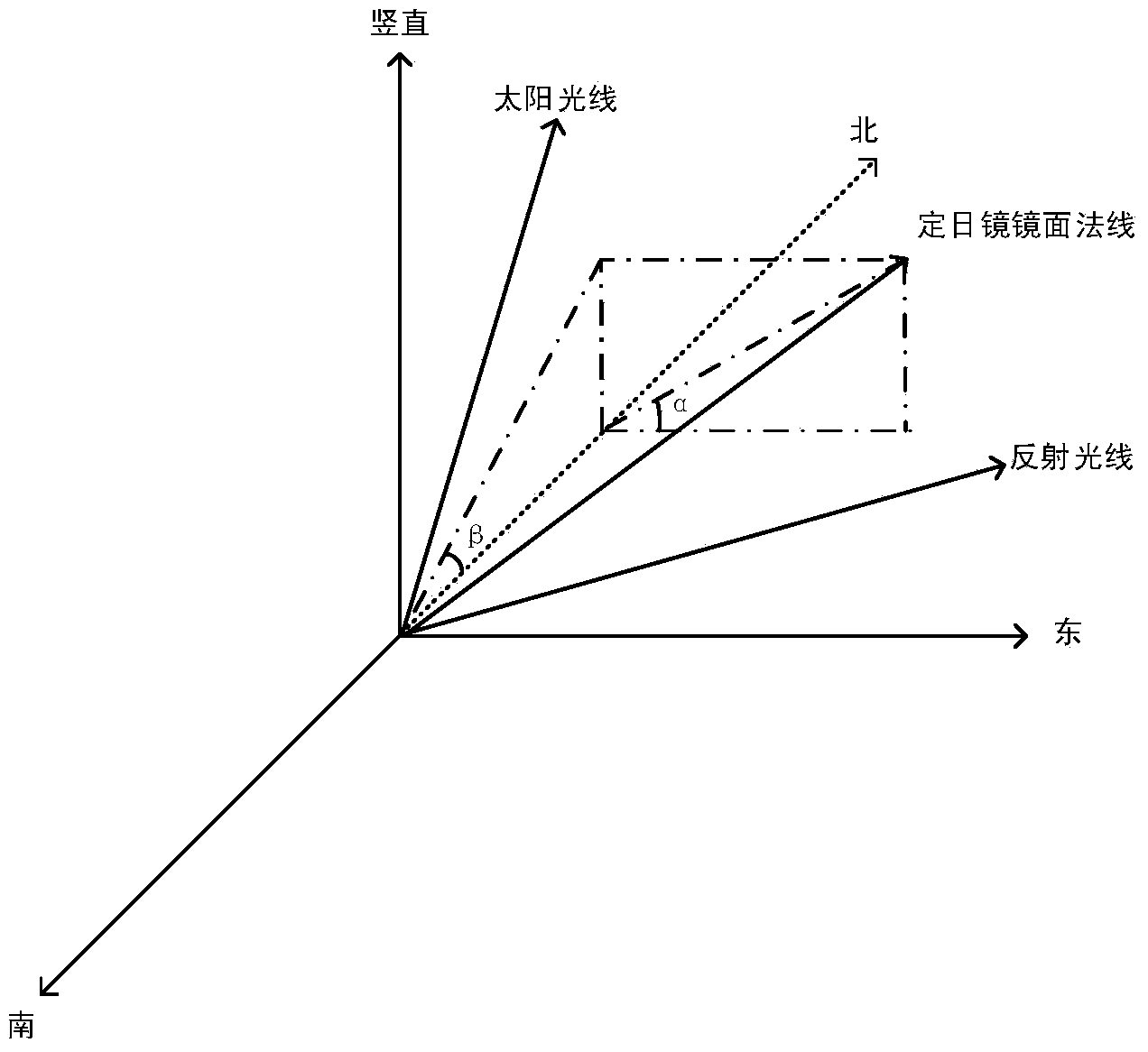

[0051] Such as figure 1 As shown, the heliostat tracking control system of the present invention includes a double-pitch heliostat, a dual-axis inclination sensor, a machine vision initial error correction system and a host control system. The local controller in the described double-pitch heliostat control device is connected with the computer in the machine vision error correction system, and the computer in the host control system is connected through a network, and the computer in the machine vision error correction system and the host control system The computers are connected through the network. The dual-axis inclination sensor is attached to the front or back of the mirror surface of the dual-elevation heliostat, and its output end is connected to the local controller in the dual-elevation heliostat control device.

[0052] The doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com