Method for improving success rate of transmission electron microscope's irradiation on sample

An electron microscope and success rate technology, which is applied to the use of wave/particle radiation for material analysis, measuring devices, instruments, etc., can solve the problems of inability to carry out transmission electron microscopy, photography, carbon film tilt and distortion, etc., to improve the success rate, Effects of cost reduction and damage rate reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Since the imaging principle of the transmission electron microscope (not shown in the figure) is that a high-energy electron beam penetrates the sample, the transmitted electrons are focused and amplified, and the detector is used to collect the signal and form an image. Since electrons are easy to scatter and be absorbed by objects, transmission electron microscopy has high requirements for sample preparation, and the requirements for sample thickness vary according to the acceleration voltage, generally around 100nm.

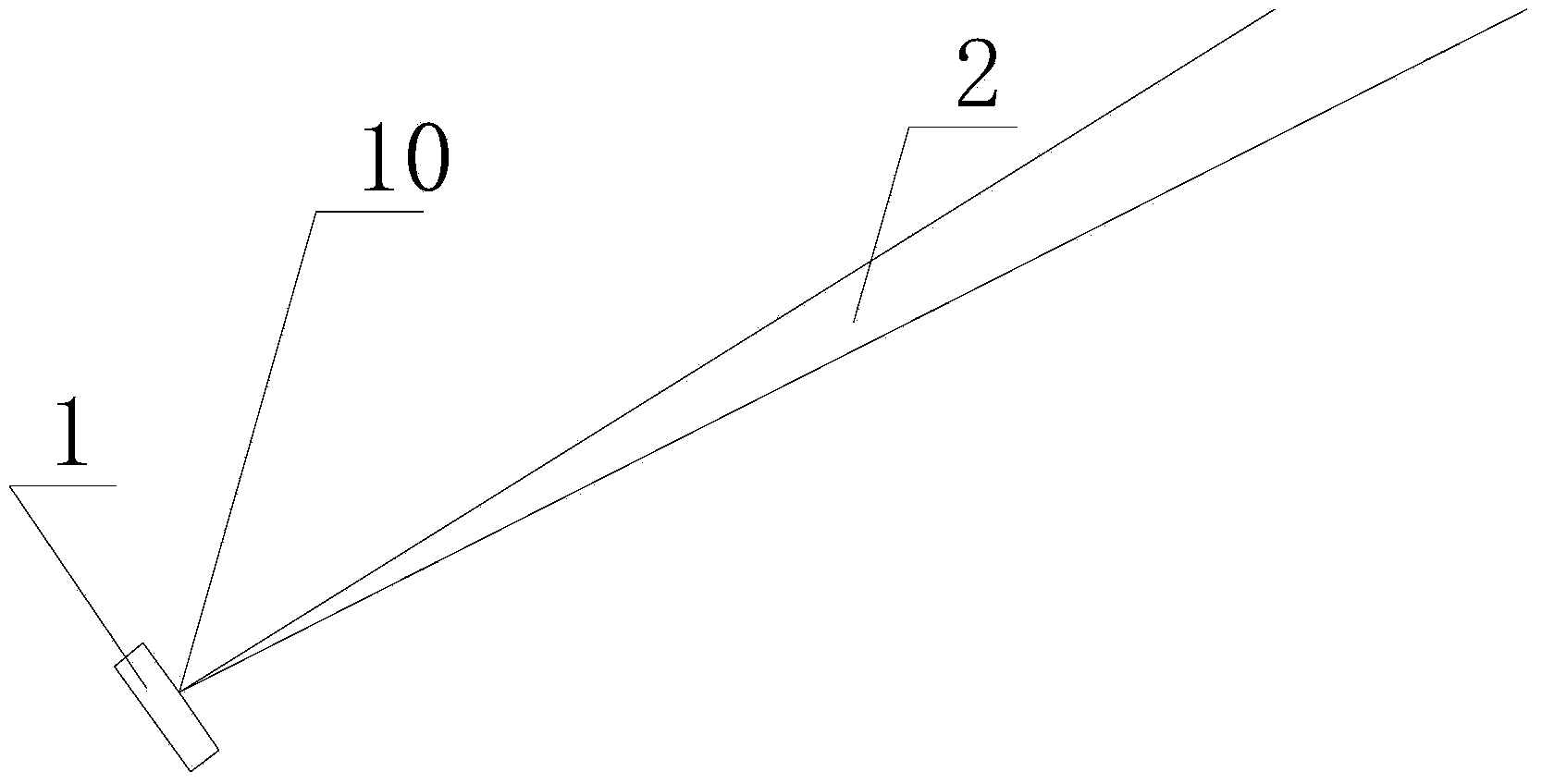

[0033] figure 1 It is a schematic diagram of glass needle adsorption sample of the present invention; as figure 1 As shown, in the semiconductor industry, focused ion beams are mostly used to prepare transmission electron microscope samples, and then a sampling system (not shown in the figure) is used to bring a glass needle 2 with a needle head 10 with a diameter of 0.2-0.5 μm close to the prepared sample 1 , using the electrostatic force between the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com