Micro-nano scale coupling vibration high-resolution measurement method

A technology of coupling vibration and measurement method, which is applied in the direction of measuring device, scanning probe microscope, instrument, etc., can solve the problems that have not been reported, achieve the effect of low price, eliminate image distortion, and improve imaging accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

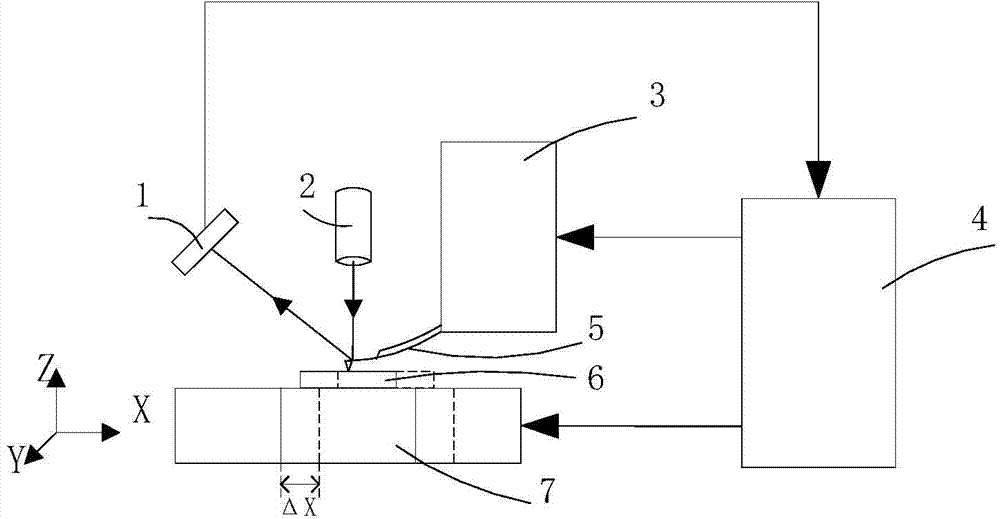

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] The steps of the inventive method are as follows:

[0027] 1) Set the AFM automatic needle insertion process and the initial state of the probe:

[0028] Such as figure 1 As shown, the stepper motor 3 drives the probe 5 to approach the surface of the sample 6 at a speed of 0.5um / s. When the photodetector 1 detects that the light spot deflection signal emitted from the laser light source 2 reflected from the back of the probe 5 exceeds 100mv , stop the stepper motor 3, and the AFM automatic needle insertion process is completed. In order to prevent the influence of the self-excited oscillation of the probe 5 caused by the separation of the probe 5 due to the inclination of the sample 6 during the vibration measurement process of the probe 5, the photodetector 1 is deflected by adjusting the elongation of the scanner 7 in the Z direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com