Method for loading gold nanoparticles on titanium dioxide nanotube

A technology of gold nanoparticles and titanium dioxide, which is applied in the field of preparation of nano-titanium dioxide catalysts, can solve the problems of low loading rate, cumbersome methods, and high reaction conditions, and achieve the effects of controllable loading, simple process, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

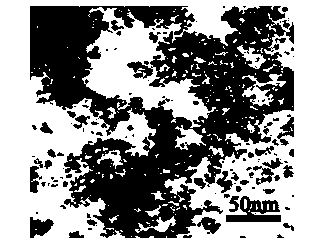

[0016] Mix 150ml ethyl titanate and 75ml n-butanol evenly and add to 1000ml HNO with a pH value of 3.5 3 solution, stirred at room temperature for 15 hours, transferred to a reaction kettle for 5 hours at 180°C, and the product was cooled, filtered, washed, and dried to obtain rutile TiO 2 Nanoparticles; 20g rutile TiO 2 Add nanoparticles into 1000ml of 10mol / L NaOH solution, stir evenly, transfer to a sealed reaction kettle, heat to 110°C for 36 hours, cool the product after taking it out, ultrasonically disperse, filter, wash, and dry to obtain TiO 2 Nanotube; 20gTiO 2 Add nanotubes to 1000ml 50% thioglycolic acid solution, stir for 3h, then add 30ml0.1mol / lHAuCl 4 solution, stirred for 3 hours, added 400ml of 1% trisodium citrate solution, transferred to a reaction kettle at 120°C for 5 hours, the product was cooled, filtered, washed, and dried to obtain TiO doped with precious metal gold. 2 nanotube.

Embodiment 2

[0018] Mix 200ml ethyl titanate and 80ml n-butanol evenly and add to 1000ml HNO with a pH value of 4 3 solution, stirred at room temperature for 15 h, transferred to a reaction kettle at 200 ° C for 6 h, and the product was cooled, filtered, washed, and dried to obtain rutile TiO 2 Nanoparticles; 50g rutile TiO 2 Add nanoparticles into 1000ml of 10mol / L NaOH solution, stir evenly, transfer to a sealed reaction kettle, heat to 110°C for 48 hours, cool the product after taking it out, ultrasonically disperse, filter, wash, and dry to obtain TiO 2 Nanotube; 50gTiO 2 Add nanotubes to 1000ml 50% thioglycolic acid solution, stir for 3h, then add 50ml0.1mol / lHAuCl 4 solution, stirred for 3 hours, added 500ml of 1% trisodium citrate solution, transferred to a reaction kettle at 120°C for 5 hours, the product was cooled, filtered, washed, and dried to obtain TiO doped with precious metal gold. 2 nanotube.

[0019]

Embodiment 3

[0021] Mix 50ml ethyl titanate and 20ml n-butanol evenly and add to 1000ml HNO with a pH value of 3 3 solution, stirred at room temperature for 10 h, transferred to a reaction kettle for 4 h at 120 ° C, and the product was cooled, filtered, washed, and dried to obtain rutile TiO 2 nanoparticles; 1 g of rutile TiO 2 Add nanoparticles into 1000ml of 10mol / L NaOH solution, stir evenly, transfer to a sealed reaction kettle, heat to 110°C for 12 hours, cool the product after taking it out, ultrasonically disperse, filter, wash, and dry to obtain TiO 2 Nanotubes; 1gTiO 2 Add nanotubes to 1000ml 50% thioglycolic acid solution, stir for 1h, then add 10ml0.1mol / lHAuCl 4 solution, stirred for 1h, added 200ml of 1% trisodium citrate solution, transferred to a reaction kettle at 120°C for 1h, the product was cooled, filtered, washed, and dried to obtain TiO doped with precious metal gold. 2 nanotube.

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com