Printing type paper microfluid chip and manufacture method thereof

A paper-based microfluidics, manufacturing method technology, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc. Cost, reduce complexity, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

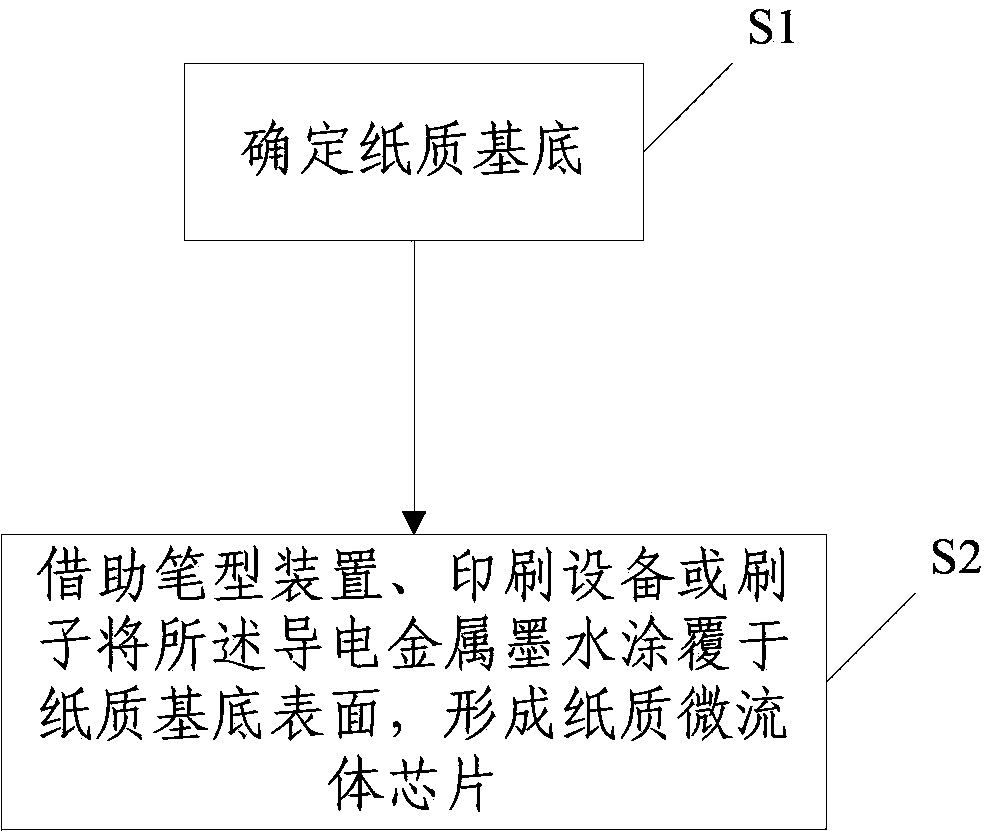

Method used

Image

Examples

Embodiment 1

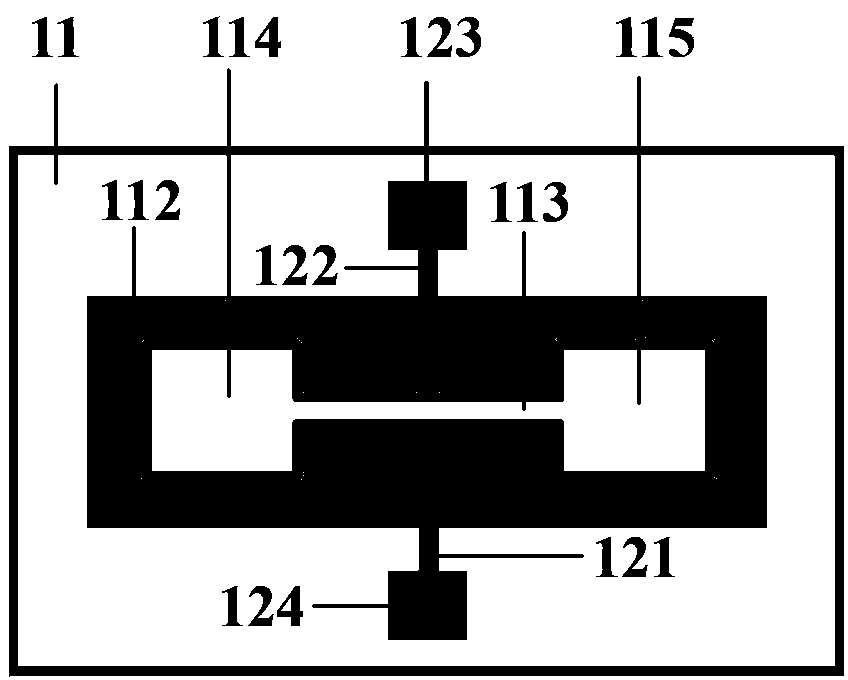

[0036] figure 2It is a schematic structural diagram of a printed paper microfluidic chip in Example 1 of the present invention, as figure 2 As shown, in this embodiment, the microfluidic chip substrate 11 is made of paper with a thickness of 0.5mm, and its part is infiltrated with paraffin to form figure 2 In the rectangular paraffin paper part 112, on this basis, a metal hard mold is used to emboss a flow channel 113 with a width of 0.1 mm on the paraffin paper part 112, and a fluid inlet pool 114 and an outlet pool 115 of 2 mm × 2 mm at both ends of the flow channel After that, at room temperature, the conductive metal ink (liquid gallium) 121 containing 0.25wt% gallium oxide is vertically coated on the upper and lower sides of the flow channel 113 in the paraffin paper 112 in the form of a line, forming an electrode 121 with a width of 0.5mm , 122, where the ends of the two electrodes are terminals 123, 124 of 2mm×2mm. Thus, the fabrication of the flow cytometry chip o...

Embodiment 2

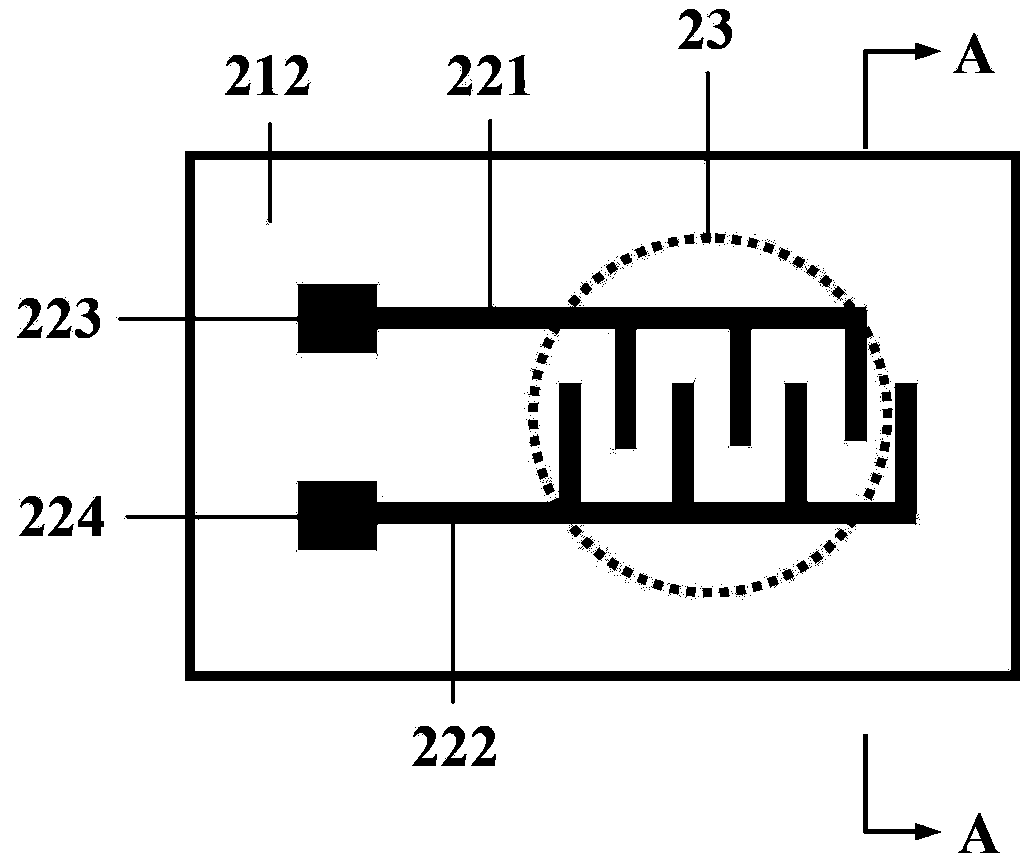

[0038] Figure 3a It is a schematic structural diagram of a printed paper microfluidic chip in Example 2 of the present invention, Figure 3b for Figure 3a A-A sectional view, such as Figure 3a-3b As shown in Fig. 1, the liquid drop directly titrated on the substrate is measured by using a channelless structure, and the electrode shape adopts a toothed structure to improve sensitivity. In this embodiment, the microfluidic chip substrate 212 is made of paper with a thickness of 0.5mm, which is completely infiltrated with paraffin; after that, at room temperature, the conductive metal ink (liquid gallium) containing 0.25wt% gallium oxide is coated in a tooth-shaped staggered form. Cover the surface of paraffin paper to form tooth-shaped electrodes 221 and 222 with a line width of 0.5 mm, and the ends of the two electrodes are terminals 223 and 224 of 2 mm×2 mm. Thus, the fabrication of the droplet fluid detection chip of this embodiment is completed. When in use, once the ...

Embodiment 3

[0040] Figure 4 It is a schematic structural diagram of a printed paper microfluidic chip in Example 3 of the present invention, as Figure 4 As shown, the difference between Embodiment 1 and Embodiment 2 is that the function of the electrode here is to exist as a heating film. In this embodiment, the microfluidic chip substrate 31 uses paper with a thickness of 0.5 mm, and its part is infiltrated with paraffin. On this basis, a metal hard mold is used to imprint a width of 0.1 mm on the paraffin paper part in a meandering form as shown in the figure. The flow channel 312 of mm, the two ends of the flow channel are a fluid inlet pool 313 and an outlet pool 314 of 2mm×2mm; after that, a metal ink (liquid gallium) 321 containing 0.25wt% gallium oxide is applied in the form of a thin film at room temperature Cover the corresponding parts of the paraffin paper, thereby forming three-stage heating films 33, 34, 35 with a width of 5mm, respectively, and the respective heating powe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com