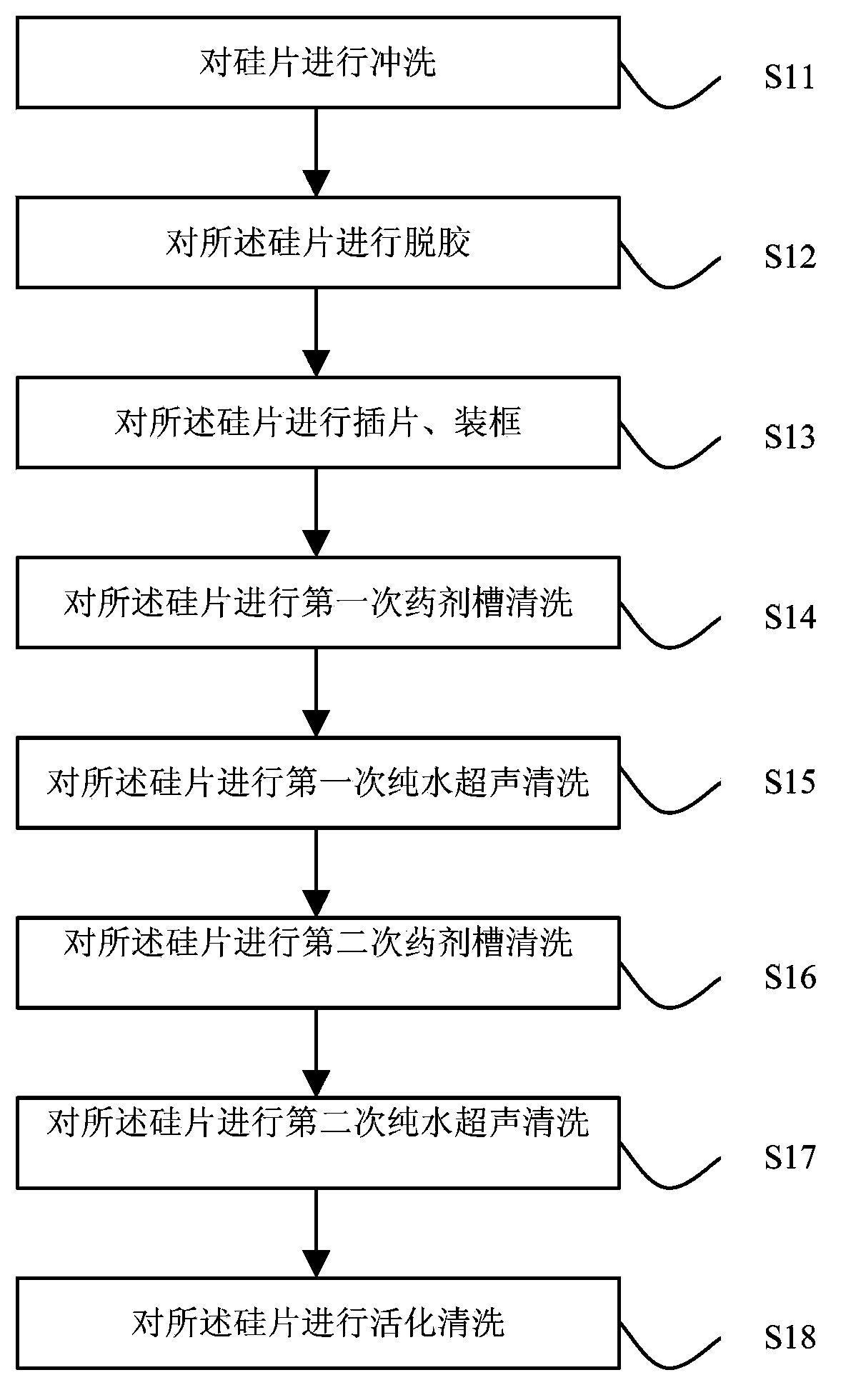

Method for cleaning diamond wire cut silicon wafers

A diamond wire cutting and silicon wafer technology, applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc., can solve the problem of poor texture uniformity, low surface cleanliness of silicon wafers, and ineffective removal of silicon Flake impurities and other problems, to achieve the effect of good uniformity and improved cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] As mentioned in the background technology section, the existing traditional cleaning method to clean silicon wafers cut by diamond wire cannot effectively remove impurities on the surface of silicon wafers. The surface uniformity is poor, that is, the pyramid coverage of the suede surface is small, resulting in low photoelectric conversion efficiency.

[0041] The reason is that after the silicon rod is cut, the atoms on the surface layer of the silicon wafer become dangling bonds due to the destruction of the chemical bonds perpendicular to the slicing direction. The large number of dangling bonds can easily absorb various impurities, such as particles, organic impurities, inorganic impurities, metals, etc. Ions, silica fume dust, etc.

[0042] Ordinary cleaning methods can only remove part of the impurities on the surface of the silicon wafer, but cannot remove the impurities with strong adhesion. For example, the hydrogen atom in the organic matter can form a strong...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com