Microelectronic component and corresponding production process

A technology of microelectronics and micromechanical components, which is applied in the directions of microelectronic microstructure devices, electrical components, microstructure technology, etc., can solve the problems of unreliable surface state of sensor elements, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The same reference numbers in the figures indicate identical or functionally identical elements.

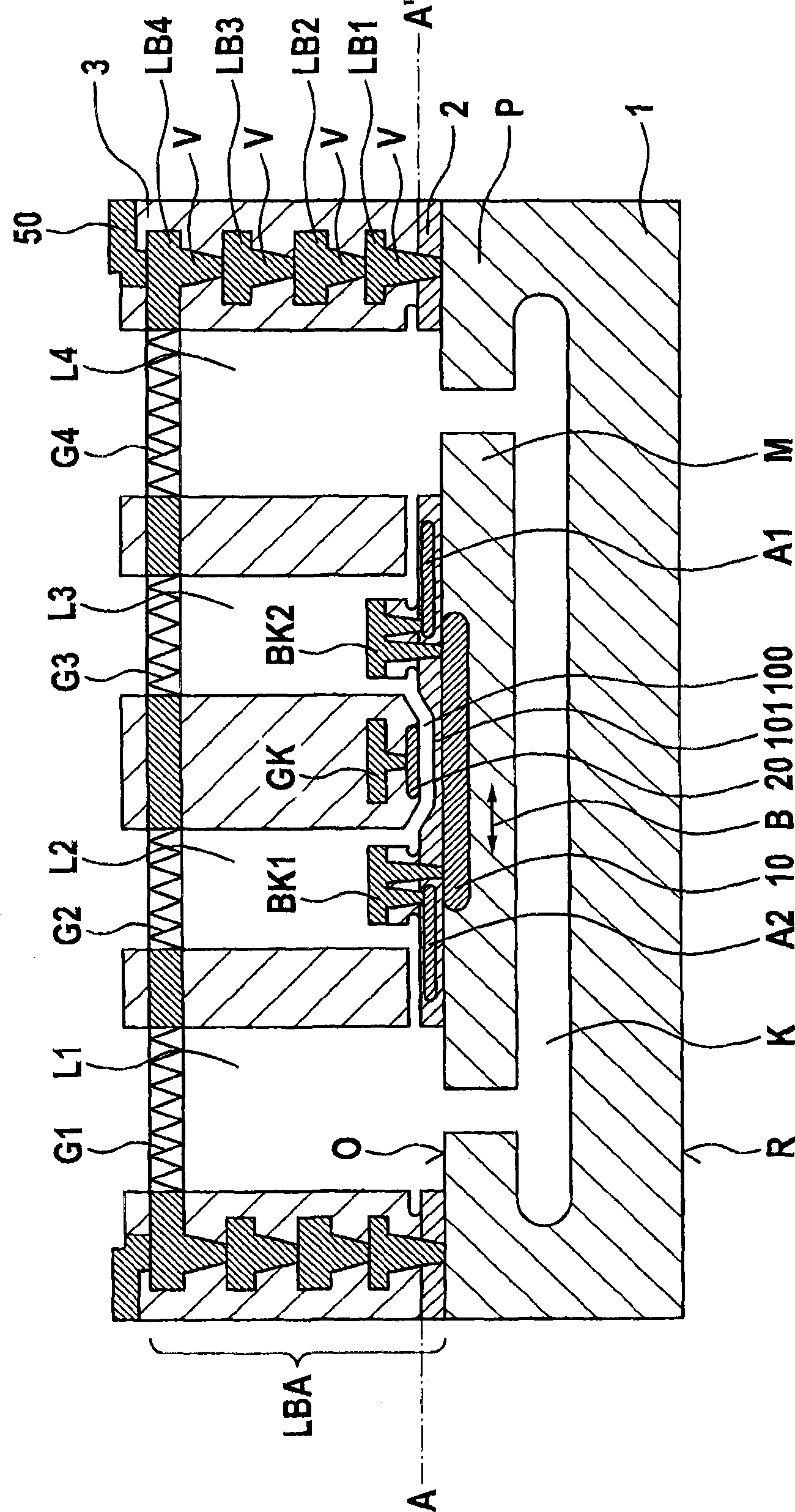

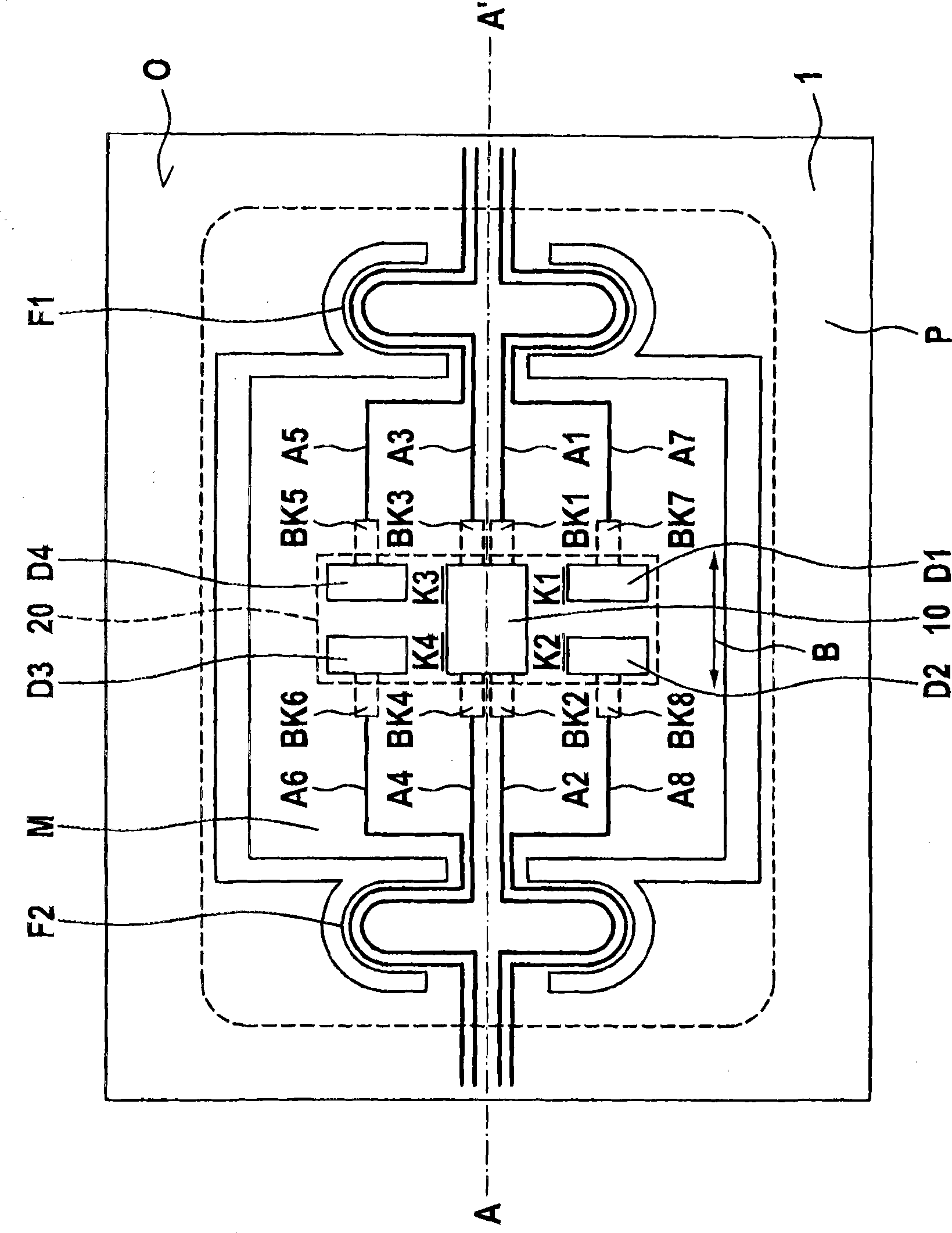

[0032] Figure 1a ), b) are schematic cross-sectional views for illustrating a microelectronic component according to a first embodiment of the present invention, more precisely, Figure 1a ) is the vertical cross-section, while Figure 1b ) is along Figure 1a ) The horizontal cross-section of line A-A'.

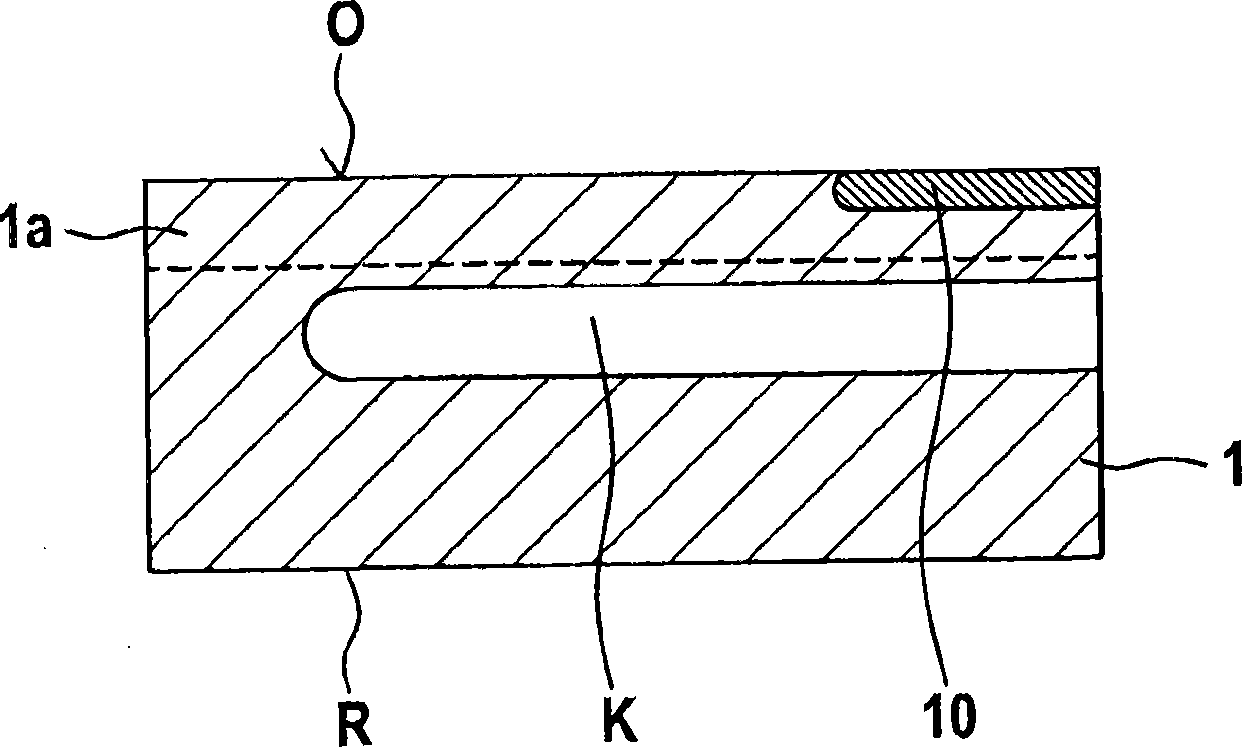

[0033] exist Figure 1a ), b) shows a micromechanical component, which is an inertial sensor with a movable channel. At this time, reference numeral 1 denotes a single-crystal silicon semiconductor substrate having a front surface O and a rear surface R. As shown in FIG.

[0034] The silicon semiconductor substrate 1 has a cavity K on which an elastically deflectable mass device M is arranged, which is connected to the periphery P of the silicon semiconductor substrate 1 via a spring device F1, F2, wherein The spring arrangement consists of a first silicon spring F1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com