Method for low-temperature preparation of nano bismuth tungstate

A technology of nano-tungsten and bismuth acid, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of high energy consumption and high conditions, and achieve the effect of high energy consumption, high conditions and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] First prepare 2mmol / L Bi(NO 3 ) 3 ·5H 2 O aqueous solution and 1mmol / L Na 2 WO 4 2H 2 40 mL of O aqueous solution. The surfactants are PVP and CTAB, and 0.12 g is added to each reactant solution. In the preparation of Bi(NO 3 ) 3 ·5H 2 In the process of O solution, first dissolve it with 5mL of 1mol / L nitric acid aqueous solution, and then add 35mL of deionized water. Under the condition of magnetic stirring, the Bi(NO 3 ) 3 ·5H 2 O solution was added dropwise to Na 2 WO 4 2H 2 O solution. The pH of the solution was adjusted to 7 by using 1 mol / L NaOH aqueous solution for pH adjustment. Transfer the resulting mixed solution into a sealed glass bottle. When the temperature of the drying oven was stable at 98°C, the glass bottle was placed in a constant temperature drying oven. After reacting for 6 hours, the obtained precipitate was washed twice with water and ethanol respectively, and then put into an oven and dried at 60°C for 1 hour. The bismuth tu...

Embodiment 2

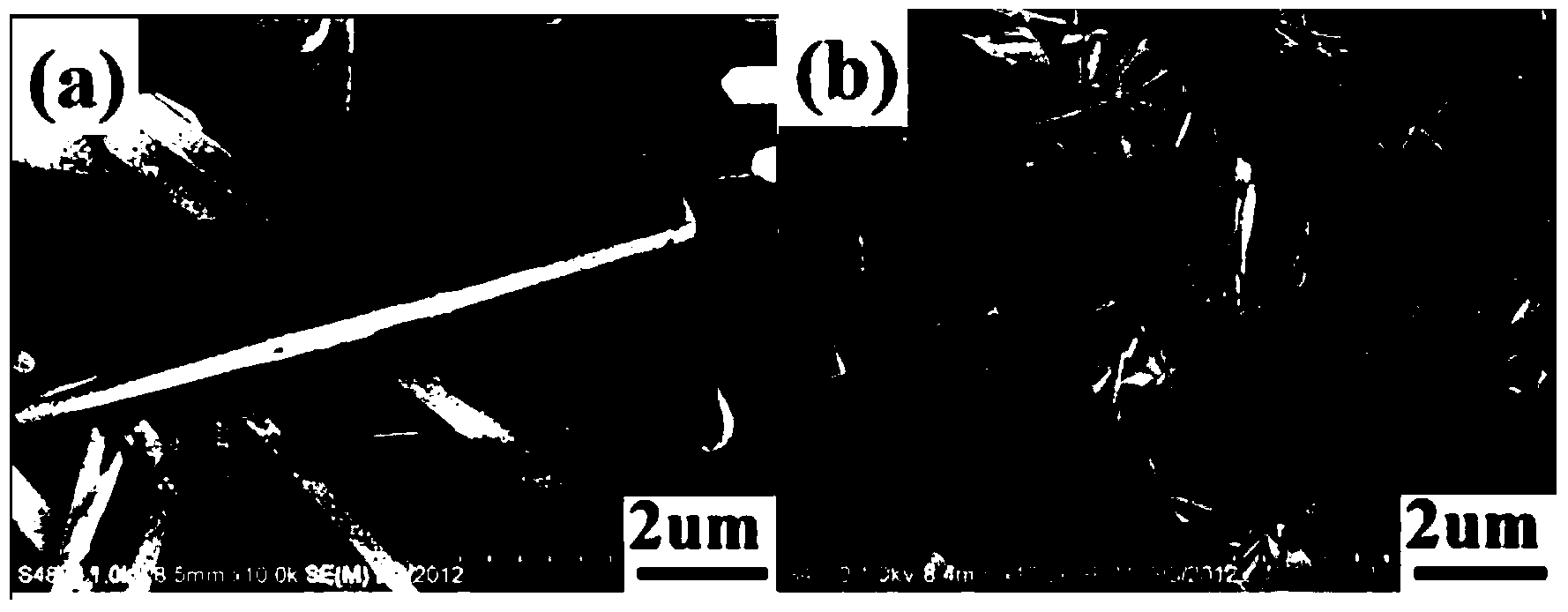

[0029] Prepare 2mmol / L Bi(NO 3 ) 3 ·5H 2 O aqueous solution and 1mmol / L Na 2 WO 4 2H 2 40 mL of O aqueous solution. 0.12 g of surfactant PVP was added to each reactant solution. In the preparation of Bi(NO 3 ) 3 ·5H 2 In the process of O solution, first dissolve it with 5mL of 1mol / L nitric acid aqueous solution, and then add 35mL of deionized water. Under the condition of magnetic stirring, the Bi(NO 3 ) 3 ·5H 2 O solution was added dropwise to Na 2 WO 4 2H 2 O solution. The pH of the solution was adjusted to 7 by using 1 mol / L NaOH aqueous solution for pH adjustment. Transfer the resulting mixed solution into a sealed glass bottle. When the temperature of the drying oven was stable at 98°C, the glass bottle was placed in a constant temperature drying oven. After reacting for 6 hours, the obtained precipitate was washed twice with water and ethanol respectively, and then put into an oven and dried at 60°C for 1 hour. The prepared bismuth tungstate is a mixed...

Embodiment 3

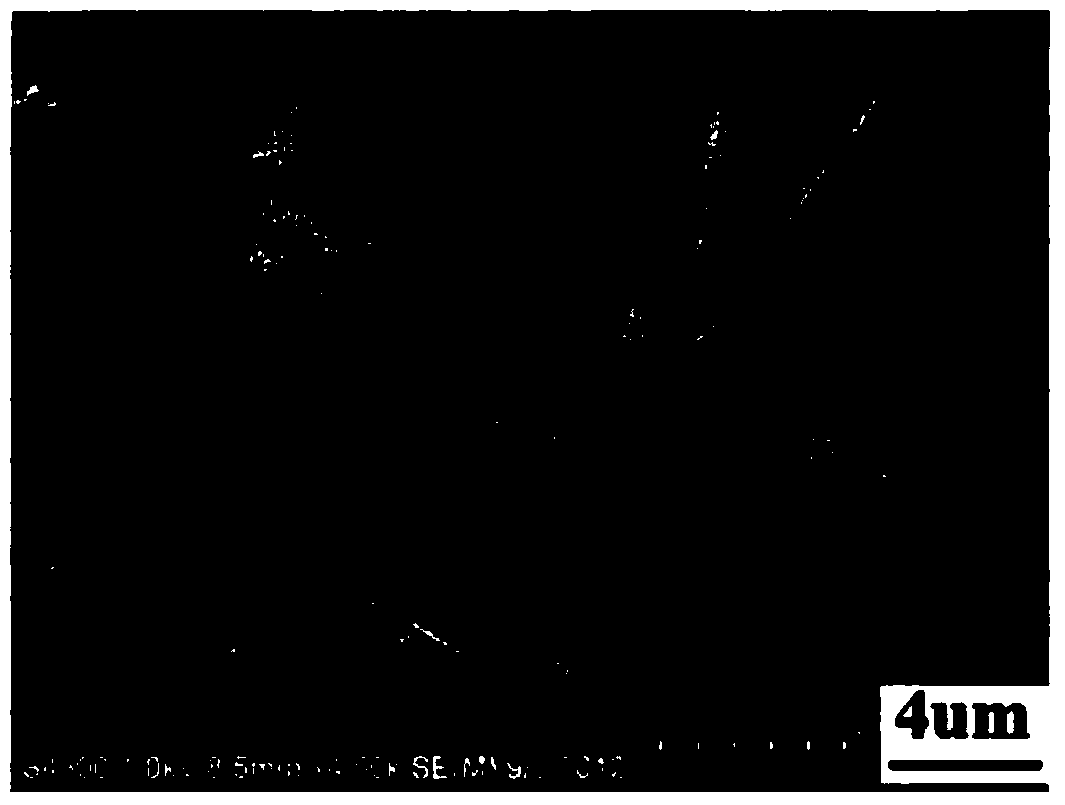

[0031] Prepare 2mmol / L Bi(NO 3 ) 3 ·5H 2 O aqueous solution and 1mmol / L Na 2 WO 4 2H 2 40 mL of O aqueous solution. 0.04 g of surfactant CTAB was added to each reactant solution. In the preparation of Bi(NO 3 ) 3 ·5H 2 In the process of O solution, first dissolve it with 5mL of 1mol / L nitric acid aqueous solution, and then add 35mL of deionized water. Bi(NO 3 ) 3 ·5H 2 O solution was added dropwise to Na 2 WO 4 2H 2 O solution. The pH of the solution was adjusted to 7 by using 1 mol / L NaOH aqueous solution for pH adjustment. Transfer the resulting mixed solution into a sealed glass bottle. When the temperature of the drying oven was stable at 98°C, the glass bottle was placed in a constant temperature drying oven. After reacting for 6 hours, the obtained precipitate was washed twice with water and ethanol respectively, and then put into an oven and dried at 60°C for 1 hour. The prepared bismuth tungstate has a nano-sheet structure, the thickness of the sheet is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com