High-salt-content inorganic wastewater fluidization treatment technique and system

A technology for inorganic wastewater and fluidized treatment, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as low energy consumption and treatment efficiency, and achieve stable and reliable operation and accurate positioning , the effect of convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

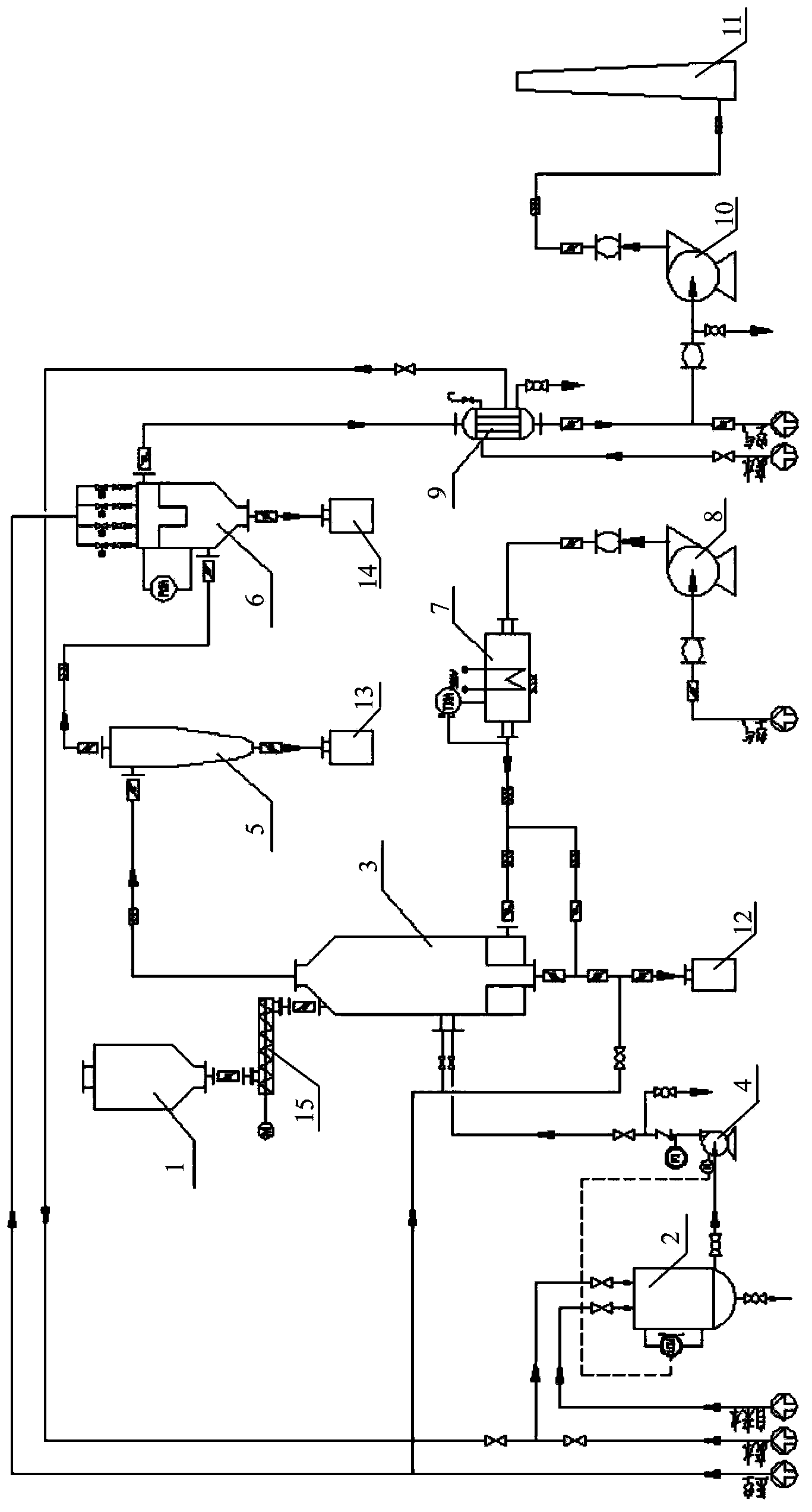

[0018] Such as figure 1 As shown, the high-salt inorganic wastewater fluidized treatment system includes a fluidized medium powder storage tank 1 (the fluidized medium adopts CaO powder) and a waste water tank 2 respectively connected to the fluidized bed drying tower 3, and the waste water tank 2 is connected with the fluidized bed A delivery pump 4 and a high-pressure nozzle are arranged between the drying towers 3 . Wastewater can be evaporated concentrated liquid or directly high-salt concentration wastewater. The wastewater is temporarily stored in the wastewater tank 2 through the pipeline. When necessary, it is transported to the fluidized bed drying tower 3 through the waste liquid delivery pump 4 and atomized by a high-pressure nozzle. After that, it is sprayed into the fluidized bed drying tower. The fluidized medium powder is loaded into the storage tank 1, and then transported into the fluidized bed drying tower 3 through the screw feeding mechanism 15.

[0019] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap