Preparation method of iron oxide water-based color paste

A water-based color paste, iron oxide technology, applied in the direction of pigment paste, etc., can solve the problems of large specific gravity, unsuitable grinding and dispersion, coarse particles of water-based color paste, poor tinting strength, etc., to improve the dispersion performance, improve production efficiency and hiding power. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

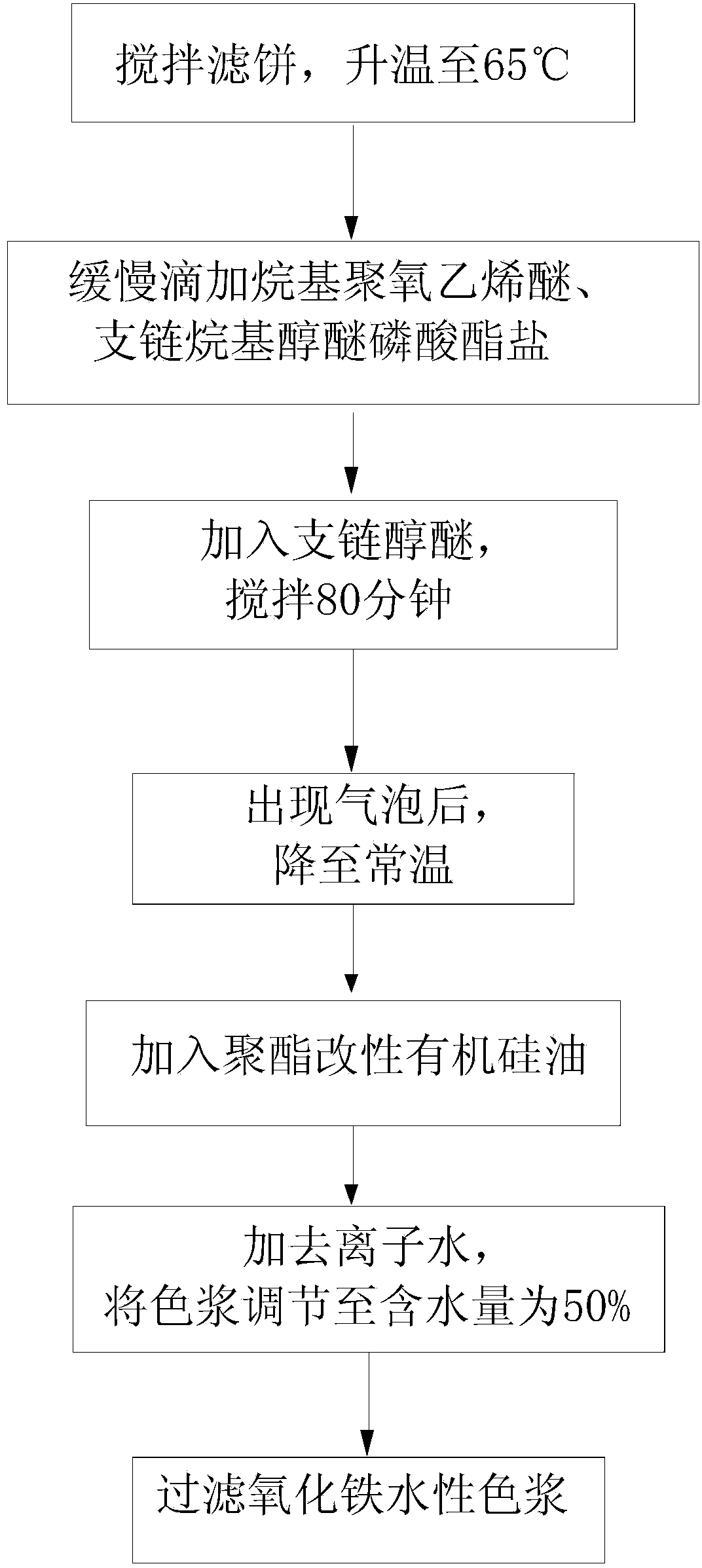

Image

Examples

Embodiment 1

[0020] (1) Use undried iron oxide pigments, also known as filter cakes. The parts by weight of water are 35, the filter cake is stirred, and the temperature is raised to 65°C.

[0021] (2) Add dropwise the alkyl polyoxyethylene ether as an anionic active agent and the branched chain alkyl alcohol ether phosphate salt as a high-performance dispersant, keep the temperature at 65°C, and keep stirring at a stirring speed of 1200 rpm ; The number of parts by weight of the alkyl polyoxyethylene ether is 3, and the number of parts by weight of the branched chain alkyl alcohol ether phosphate salt is 4; the slow dropwise addition is completed within 50 minutes.

[0022] (3) Add branched alcohol ether as a supplementary wetting agent, keep the temperature at 65° C., and keep stirring for 80 minutes; the weight part of branched alcohol ether is 2.

[0023] (4) After bubbles appear, cool down to room temperature; keep stirring.

Embodiment 2

[0028] (1) Use undried iron oxide pigments, also known as filter cakes. The parts by weight of water are 45, the filter cake is stirred, and the temperature is raised to 75°C.

[0029] (2) Add dropwise the alkyl polyoxyethylene ether as an anionic active agent and the branched chain alkyl alcohol ether phosphate salt as a high-performance dispersant, keep the temperature at 75°C, and keep stirring at a stirring speed of 1300 rpm ; The number of parts by weight of the alkyl polyoxyethylene ether is 6, and the number of parts by weight of the branched chain alkyl alcohol ether phosphate salt is 8; the slow dropwise addition is completed within 70 minutes.

[0030] (3) Add branched chain alcohol ether as a supplementary wetting agent, keep the temperature at 75° C., and keep stirring for 100 minutes; the weight part of branched chain alcohol ether is 3.

[0031] (4) After bubbles appear, cool down to room temperature; keep stirring.

Embodiment 3

[0036] (1) Use undried iron oxide pigments, also known as filter cakes. The parts by weight of water are 40, the filter cake is stirred, and the temperature is raised to 70°C.

[0037] (2) Add dropwise the alkyl polyoxyethylene ether as an anionic active agent and the branched chain alkyl alcohol ether phosphate salt as a high-performance dispersant, keep the temperature at 70°C, and keep stirring at a stirring speed of 1300 rpm ; The number of parts by weight of the alkyl polyoxyethylene ether is 4, and the number of parts by weight of the branched chain alkyl alcohol ether phosphate salt is 6; the slow dropwise addition is completed within 60 minutes.

[0038] (3) Add branched chain alcohol ether as a supplementary wetting agent, keep the temperature at 70° C., and keep stirring for 90 minutes; the weight part of branched chain alcohol ether is 2.5.

[0039] (4) After bubbles appear, cool down to room temperature; keep stirring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com