Method for Zr-based hydrogen storage alloy deposition of Pd film and plating solution for chemical plating

A hydrogen storage alloy and electroless plating technology, applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problems of waste of precious metal palladium impurities, poor stability of plating solution, etc., and achieve low equipment requirements and low cost Low, fast deposition rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

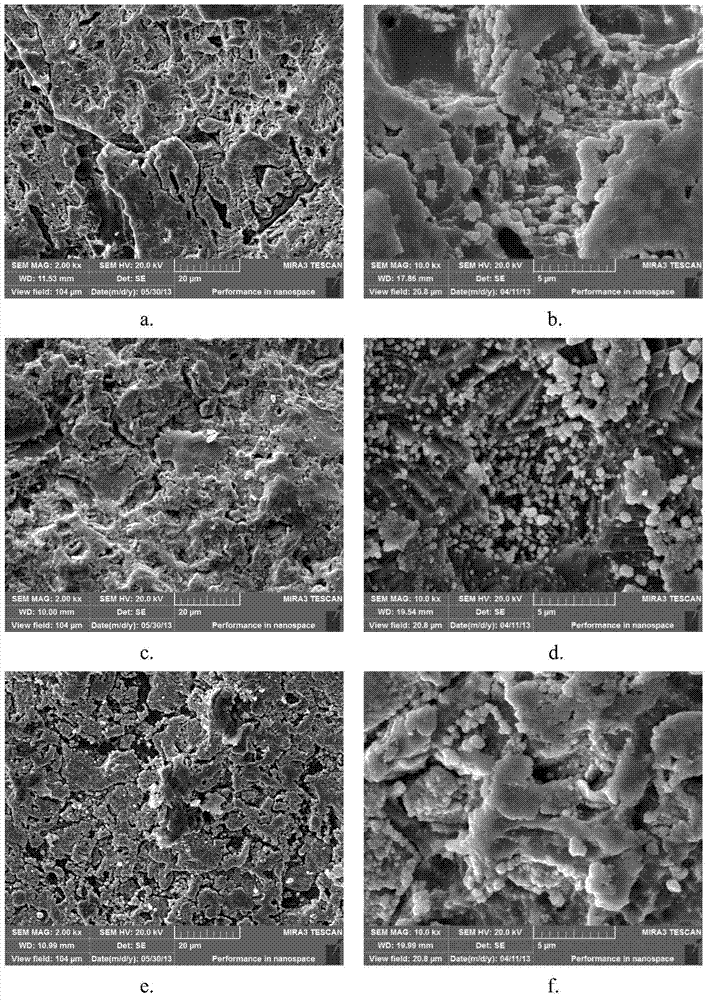

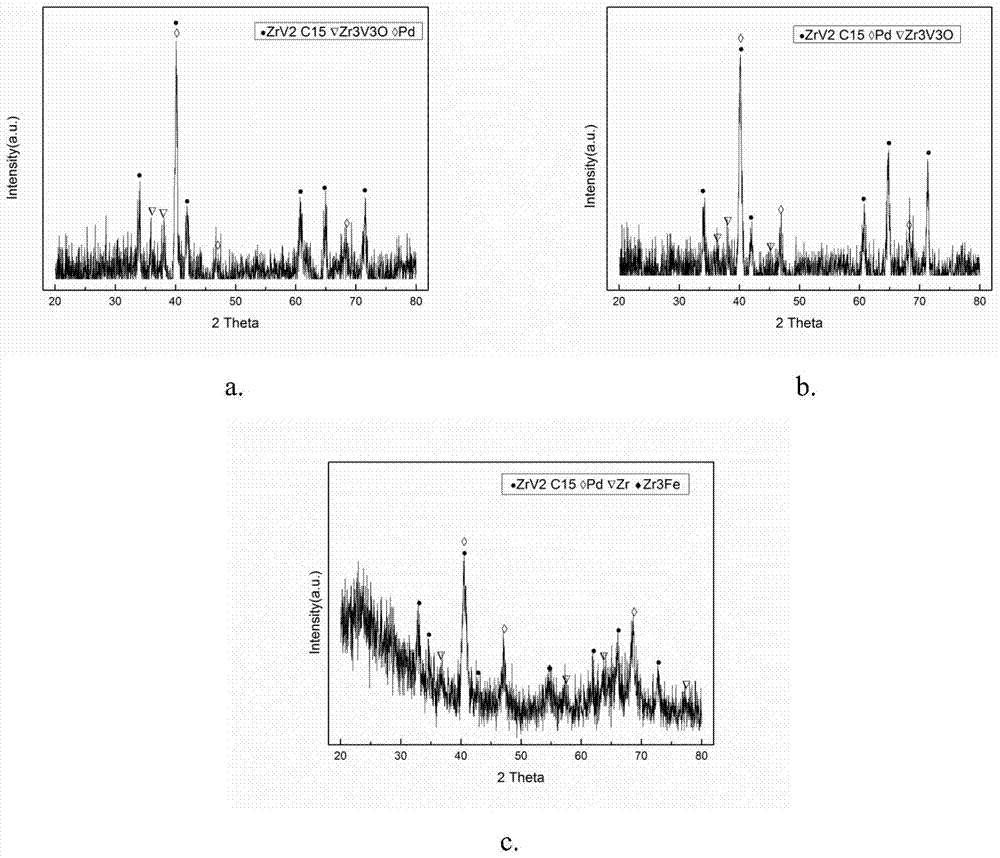

[0030] This embodiment is through electroless plating process in ZrV 2 A method for depositing a Pd film on the surface of alloy particles. ZrV 2 The alloy is mechanically crushed into alloy particles with a particle size of 0.5-1.5mm. The technique that the electroless plating that adopts in the present invention prepares Pd film, concrete steps are:

[0031] Step 1, surface treatment of the alloy particle matrix. ZrV by conventional method 2 Surface pretreatment of alloy particles. The substrate surface treatment includes sanding off the ZrV 2 oxide layer on the alloy surface, and the ZrV 2 The alloy particles were ultrasonically cleaned in absolute ethanol for 5 minutes, and the ZrV was taken out after cleaning 2 Alloy particles, then ZrV 2 Alloy particles were ultrasonically cleaned in acetone for 5 minutes to remove ZrV 2 Oil stains on the surface of alloy particles.

[0032] Step 2, pretreatment of the alloy particle matrix before electroless plating. The pret...

Embodiment 2

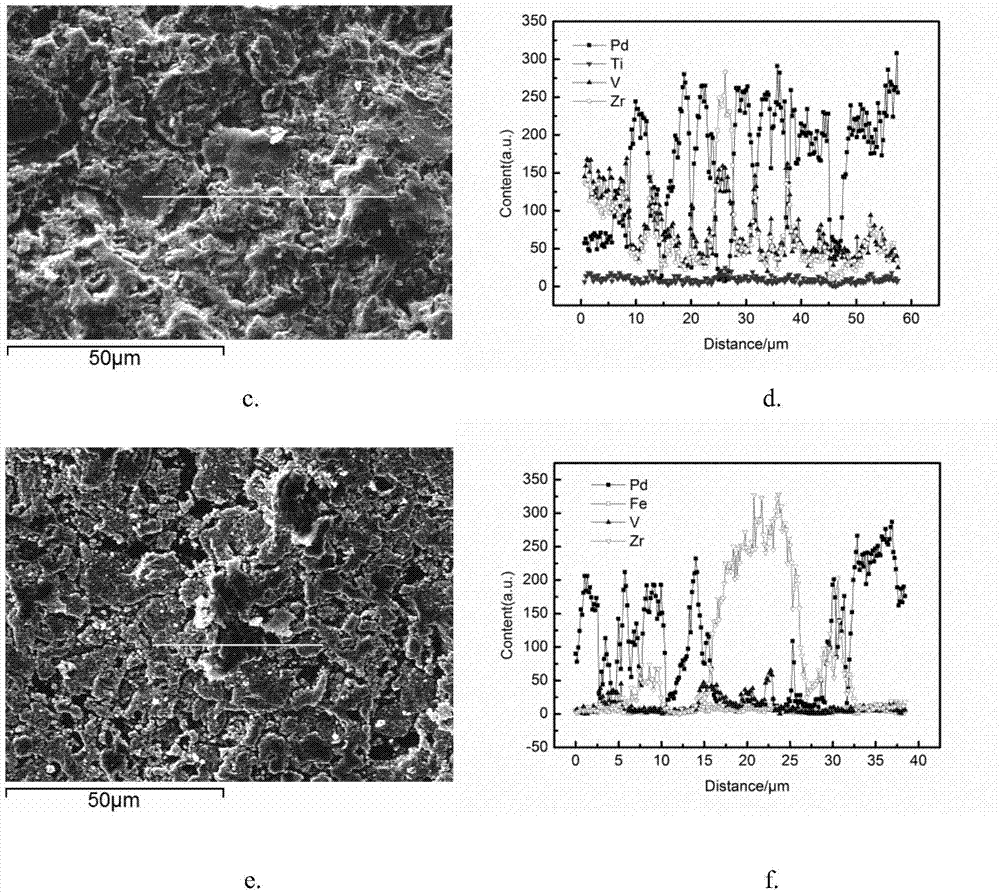

[0056] In this embodiment, the electroless plating process is carried out on Zr 0.9 Ti 0.1 V 2 A method for depositing a Pd film on the surface of alloy particles. Will Zr 0.9 Ti 0.1 V 2 The alloy is mechanically crushed into alloy particles with a particle size of 0.5-1.5mm. The electroless plating that adopts in the present invention prepares the pretreatment process of Pd film, concrete steps are:

[0057] Step 1, surface treatment of the alloy particle matrix. Zr by conventional method 0.9 Ti 0.1 V 2 Surface pretreatment of alloy particles. The surface treatment of the substrate includes sanding off the Zr 0.9 Ti 0.1 V 2 The oxide layer on the surface of the alloy, and the Zr 0.9 Ti 0.1 V 2 The alloy particles were ultrasonically cleaned in absolute ethanol for 5 minutes, and the Zr 0.9 Ti 0.1 V 2 Alloy particles, then Zr 0.9 Ti 0.1 V 2 The alloy particles were ultrasonically cleaned in acetone for 5 minutes to remove Zr 0.9 Ti 0.1 V 2 Oil stains o...

Embodiment 3

[0082] This embodiment is a method for depositing a Pd film on the surface of St707 alloy particles through an electroless plating process. The St707 alloy is mechanically crushed into alloy particles with a particle size of 0.5-1.5 mm. The electroless plating that adopts in the present invention prepares the pretreatment process of Pd film, concrete steps are:

[0083] Step 1, surface treatment of the alloy particle matrix. The surface of the St707 alloy particles was pretreated by conventional methods. The surface treatment of the substrate includes grinding off the oxide layer on the surface of the St707 alloy with sandpaper, and ultrasonically cleaning the St707 alloy particles in absolute ethanol for 5 minutes, taking out the St707 alloy particles after cleaning, and then placing the St707 alloy particles in acetone Ultrasonic cleaning for 5 minutes to remove the oil on the surface of the St707 alloy particles.

[0084] Step 2, pretreatment of the alloy particle matrix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com