Gas-phase antirust dispersing body

A gas-phase anti-rust and shell technology, which is used in the field of gas-phase corrosion inhibitor and metal protection, can solve the problems of increasing the contact resistance of electrical connection, easy oxidation of the contact surface, accidents, etc., and achieves long anti-rust period, convenient operation, Easy to use and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of the vapor phase antirust dispersion of the present invention: by weight parts, the components of the gas phase antirust corrosion inhibitor used are as follows:

[0024]

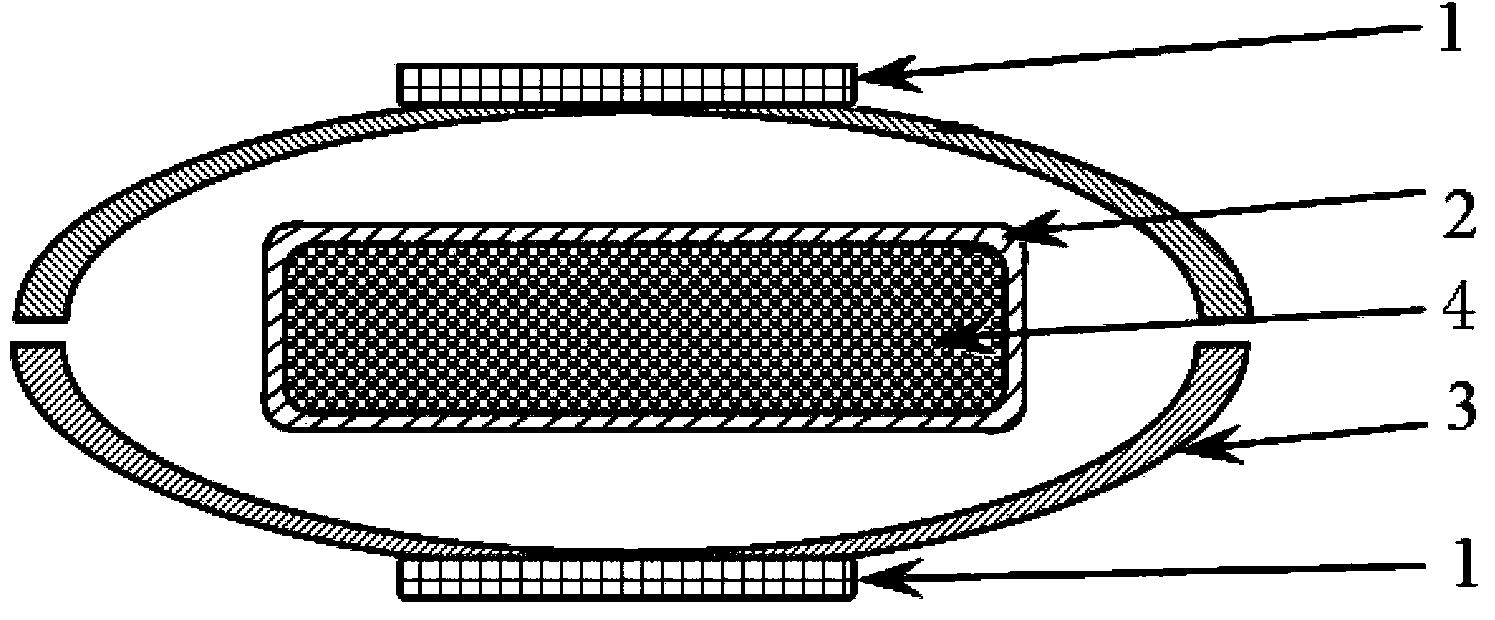

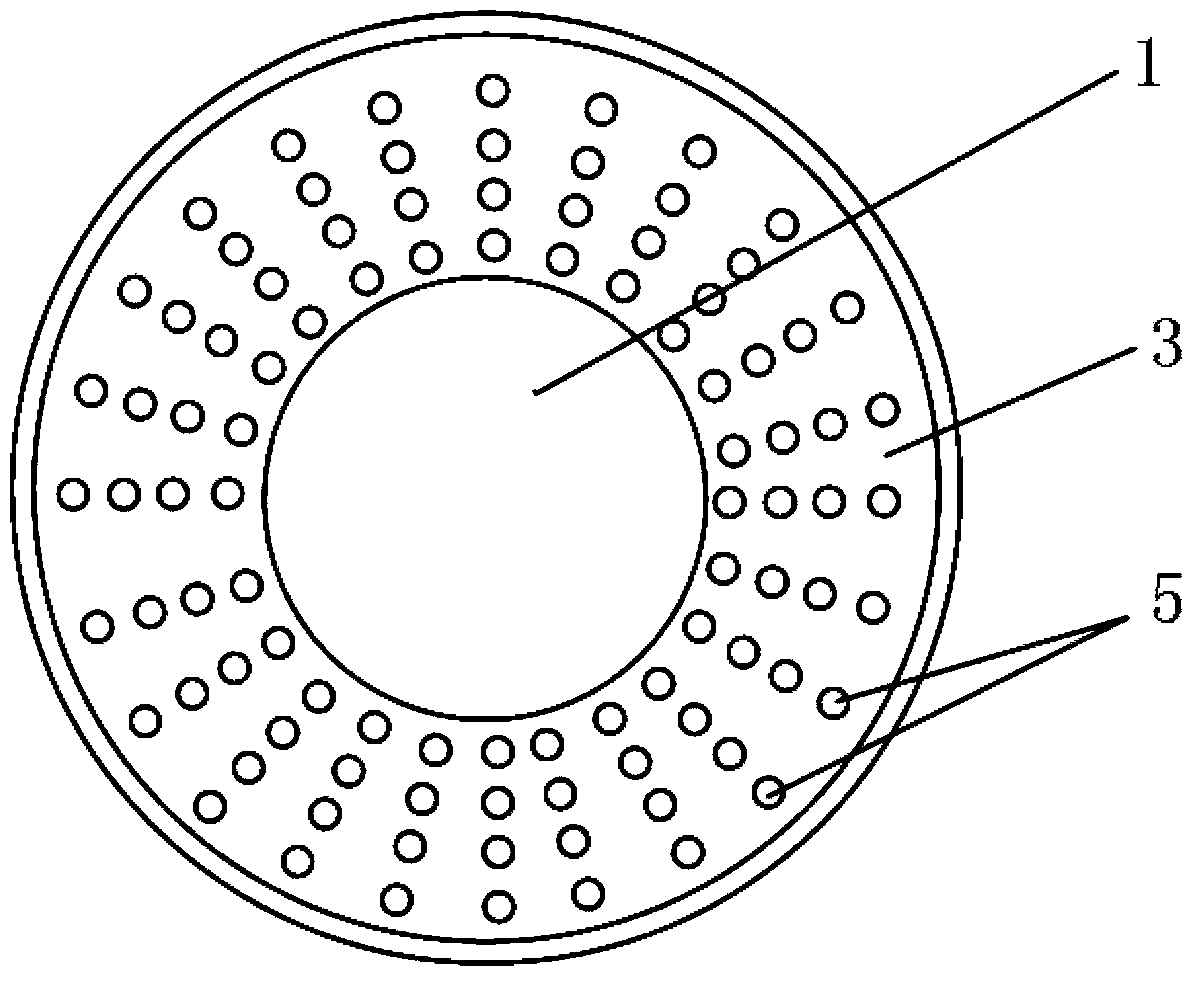

[0025] Grind and weigh the raw materials of each component of the gas phase corrosion inhibitor according to the above ratio, then fully mix the components, filter with a sieve, and re-grind and filter the large particle raw materials. Put the prepared vapor phase anti-rust and corrosion inhibitor into the air-permeable packaging material and heat seal it. Put the gas-phase anti-rust and corrosion inhibitor coated with gas-permeable packaging materials into the protective box outside the body, fit the two hemispherical shells together, and stick them on the plane outer surface of one hemispherical shell The magnet sheet, and the logo on the plane of the other hemispherical shell, that is, a vapor phase anti-rust diffuser.

[0026] The volume of an electrical control cabinet is 0.3m ...

Embodiment 2

[0028] The preparation of the vapor phase antirust dispersion of the present invention: the difference from Example 1 is that the components of the vapor phase antirust corrosion inhibitor are as follows:

[0029]

[0030] Stick self-adhesive styrofoam on the plane of one hemispherical shell of the vapor phase antirust diffuser, and stick a logo on the plane of the other hemispherical shell.

[0031] An electronic component manufacturer has several semi-finished product turnover boxes for temporary storage of semi-finished electronic components or parts. The storage period is 1-3 months. 3 In the space, a vapor phase anti-rust diffuser in this embodiment is installed, and long-term observation shows that it can effectively prevent the oxidation of the metal of the electronic component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com