Non-needle electrostatic spinning device

An electrospinning, needle-free technology, applied in textiles and papermaking, filament/thread forming, fiber treatment, etc., can solve the problem of uneven distribution of electrospinning nanofibers, increasing jet instability, affecting the quality of nanofibers, etc. Problems, to avoid electrostatic interference and electric field concentration phenomenon, reduce electrostatic interference, reduce the effect of charge density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

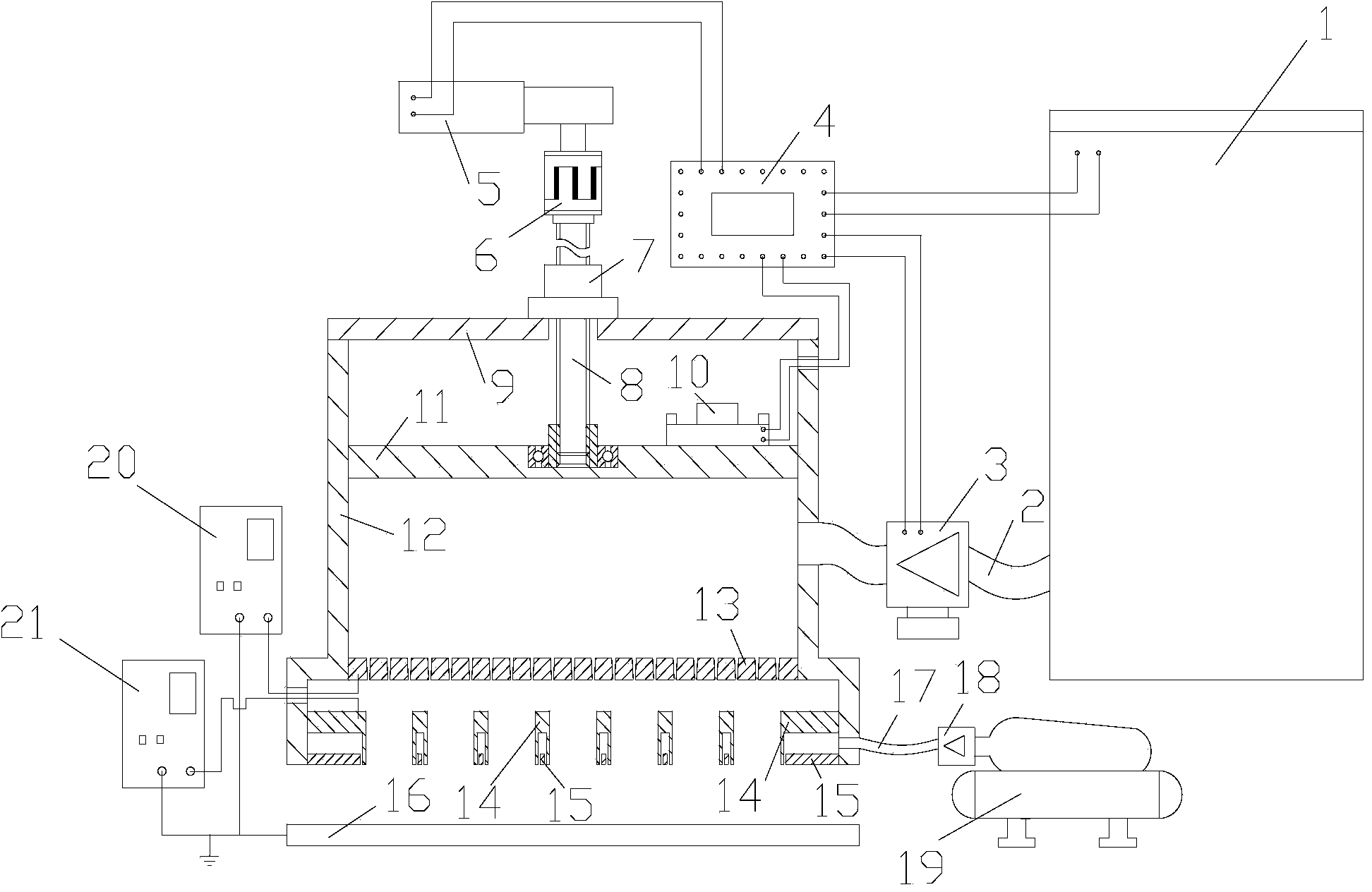

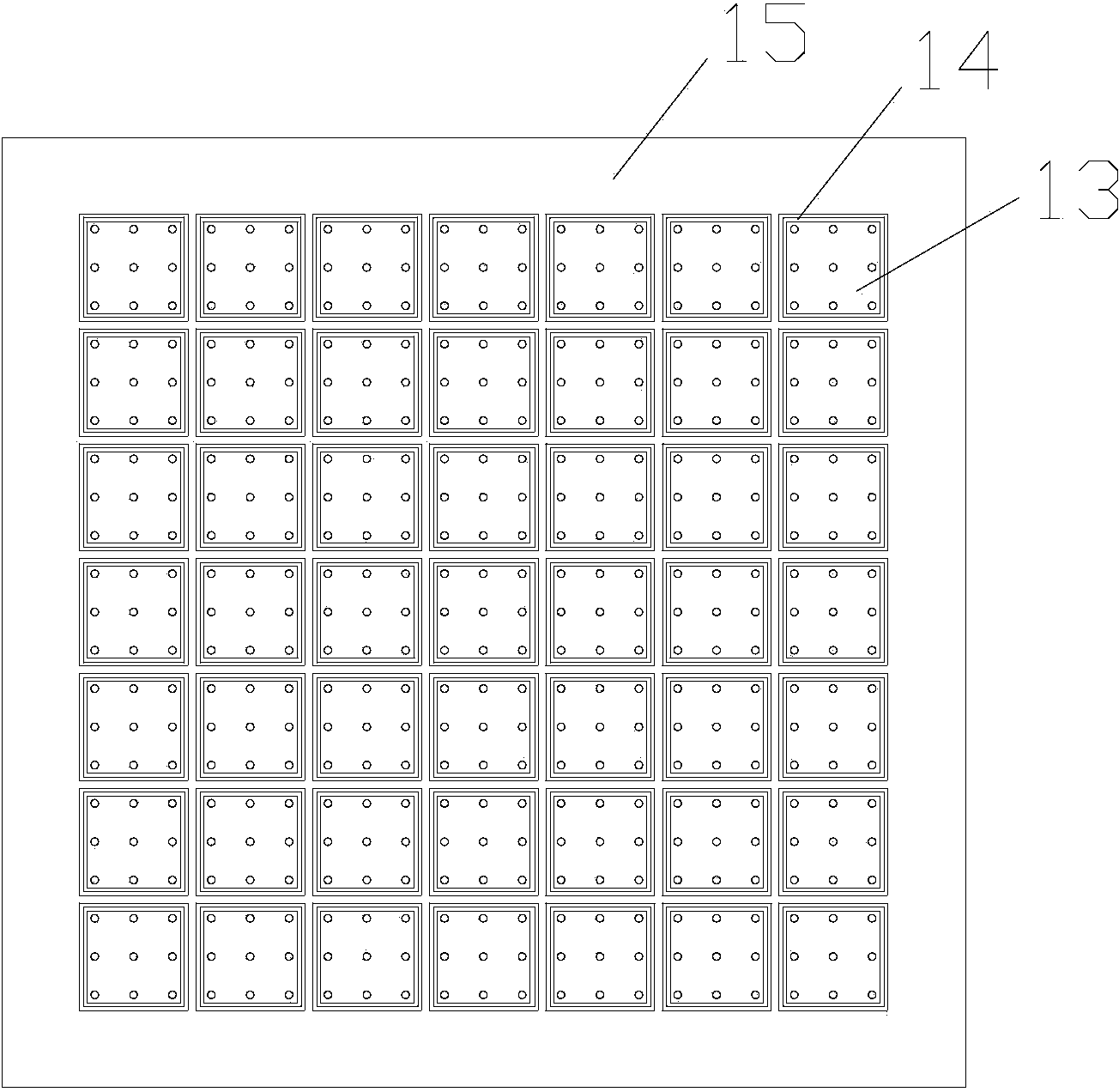

[0019] exist figure 1 Among them, the main control board 4 can communicate with and control the components connected to it, the servo motor 5 is electrically connected to the main control board 4, the output shaft of the servo motor 5 is connected to one end of the coupling 6, and the other end of the coupling 6 is connected to The ball screw 8; the cover plate 9 is fixed on the upper end of the guide cylinder 12, the cover plate 9 has a through hole, the ball bearing 7 is fixed at the center of the cover plate 9, and is tightly connected with the ball bearing 7, during the rotation of the ball screw 8 Under the helical cooperation with the ball bearing 7, the ball screw 8 will move up and down; the other end of the ball screw 8 passes through the through hole on the cover plate 9, and is connected with the guide plate 11 directly below the cover plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Upper mouth diameter | aaaaa | aaaaa |

| Lower mouth diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com