Flame-retardant finishing method for curtain fabric

A technology for flame retardant finishing and fabrics, which is applied in fiber processing, textile and papermaking, fiber types, etc. It can solve problems such as insufficient flame retardant effect and durability, unreasonable flame retardant concentration, processing time and temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

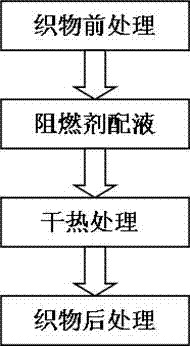

[0017] The specific processing method is as follows:

[0018] a) Fabric pre-treatment, before the curtain fabric is subjected to flame-retardant finishing, the fabric is clean and absorbent through pre-treatment to ensure that the flame retardant can penetrate well and avoid possible chemical reactions between chemicals. The pre-treatment process is: first pre-treatment agent liquid preparation, the pre-treatment agent formula is: sodium carbonate 2g / L, 30% sodium hydroxide 2g / L, hydrogen peroxide 5g / L, degreasing scouring agent 0.5g / L, bath Ratio 1:30; then put the curtain fabric into the prepared pretreatment agent solution, heat up to 80°C for heat reaction treatment for 20 minutes; then wash with hot water at 90°C for 5 minutes; after hot cleaning, wash at room temperature, wash The drying time is 5 minutes; finally, drying is carried out, the drying temperature is 105°C, and the drying time is 3 minutes.

[0019] b) Flame retardant preparation, the preparation process is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com